seitz 555

6X45 Custom Mini 14

I'll start off by stating this is going to be a long winded post. I have a Mini 14 that just won't shoot. When I got it, I was well aware of the Mini's reputation for not being exactly a tack driver, with out of the box groups being 5 to 9 inches common. But I thought I could at least get one to shoot well enough to cover the group with a snuff can lid at 100 yds. Boy was I wrong.

Here is my gun; Mini 14 chambered in 6x45 built by ARS out of Midland, Texas (they are no longer in business). It came with a synthetic Choate stock which was bedded by those folks I assume. When I would lock the trigger into the action it was very hard (required much more force than I thought it should), so I purchased an OEM Ruger stock for the gun. This new stock needed to be bedded so I completed that and let the bedding cure for 8 days.

I have loaded 55,58,60,62,69,70,75 and 87 grain bullets with various powders. Powders were Win. 748, AA LT-30 and AA2230 being the powders that shot best in the gun. The lighter bullets 55, 58 and 60 have shot the best, though not very good. Loads that have performed the best to date are 28 gr. 748 - 26.5 gr 2230 and 22.5 gr LT-30 all with either a 55 gr Sierra Blitzking or a 58 gr Hornady V-max.

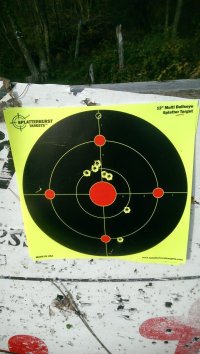

The 3 or 5 shot groups are all over the place. First shot may be 3" low and left 2" next shot on the vertical centerline and right 1" nest two shot within an inch of the second shot and the last shot 6" high and 2" left. That pattern to some degree repeats itself every group. One exception is the 1 or 2 shots that are very far off might come at any time in the group. It may be the middle shots that go wild or the last or first ones, no real pattern.

I was in hopes that a custom barrel would perform much better than this one has.

Any suggestions you could offer would be greatly appreciated.

Here is my gun; Mini 14 chambered in 6x45 built by ARS out of Midland, Texas (they are no longer in business). It came with a synthetic Choate stock which was bedded by those folks I assume. When I would lock the trigger into the action it was very hard (required much more force than I thought it should), so I purchased an OEM Ruger stock for the gun. This new stock needed to be bedded so I completed that and let the bedding cure for 8 days.

I have loaded 55,58,60,62,69,70,75 and 87 grain bullets with various powders. Powders were Win. 748, AA LT-30 and AA2230 being the powders that shot best in the gun. The lighter bullets 55, 58 and 60 have shot the best, though not very good. Loads that have performed the best to date are 28 gr. 748 - 26.5 gr 2230 and 22.5 gr LT-30 all with either a 55 gr Sierra Blitzking or a 58 gr Hornady V-max.

The 3 or 5 shot groups are all over the place. First shot may be 3" low and left 2" next shot on the vertical centerline and right 1" nest two shot within an inch of the second shot and the last shot 6" high and 2" left. That pattern to some degree repeats itself every group. One exception is the 1 or 2 shots that are very far off might come at any time in the group. It may be the middle shots that go wild or the last or first ones, no real pattern.

I was in hopes that a custom barrel would perform much better than this one has.

Any suggestions you could offer would be greatly appreciated.