You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oh no!! My first squib load and in my LCR!

- Thread starter Mus408

- Start date

Help Support Ruger Forum:

Luckyducker

Single-Sixer

My wife and I were doing some plinking some years ago and while she was shooting my Taurus M66 357mag loaded with 158 grain cast bullets in 38spec cases I heard a round go "pop" and ordered her to stop shooting. I checked the gun and the bullet was still crimped in the case but the primer had fired, and when I pulled the bullet after we returned home I found there was no powder in the case (mea culpa, as I roll my own). Evidently I crimp hard enough that the primer didn't produce enough pressure to move the slug. I have twice had the experience while shooting rifles that mis-fired that the primers were duds. Oh well, feces happens!

Bullet was an Xtreme copper plated and tapped out easy with wood dowel.

These have a slight knurled crimp groove and looked like a good crimp pressure on the bullet.

So I assume maybe light powder charge or a not so hot primer fire.

Could be just a plain mess up on my part with no powder..but the Dillon 550 press has a very positive

powder drop.

These have a slight knurled crimp groove and looked like a good crimp pressure on the bullet.

So I assume maybe light powder charge or a not so hot primer fire.

Could be just a plain mess up on my part with no powder..but the Dillon 550 press has a very positive

powder drop.

I had one a couple years ago in my SP101. I was shooting some light 327 loads, trying to work up a good medium to full power load. Just not enough oomph to move the bullet.

Same as you said, a sort of light "pop." Luckily I was paying attention and stopped shooting. I used a brass rod and a few light taps and problem solved. No big deal.

I would bet in your case it was a light powder charge. I know that was the situation with me. That or perhaps the copper plating was a little bit thicker on that bullet and it just got stuck. Or a combination of the two.

Same as you said, a sort of light "pop." Luckily I was paying attention and stopped shooting. I used a brass rod and a few light taps and problem solved. No big deal.

I would bet in your case it was a light powder charge. I know that was the situation with me. That or perhaps the copper plating was a little bit thicker on that bullet and it just got stuck. Or a combination of the two.

I had a squib in 1970 and learned my lesson. I drove over an hour to shoot, ran one cylinder full and the second round of the next cylinder full; "pfffft". No tools on hand so I had to drive another hour home after only 6 rounds. I now look in every case I charge with powder.

I have slugged many barrels since and I use a brass rod (brass won't split/splinter). I've read of wood dowels splintering in the bore and wedging in between the bullet and barrel getting stuck pretty hard. I keep a 12" rod in my range box and when I shoot a rifle I have one 36" long that I take along...

I bought one of these; 1/4"x6' which gave me a few "squib rods" for less than $15.00. https://www.mcmaster.com/#standard-brass-alloy-rods/=1671ghx

I have slugged many barrels since and I use a brass rod (brass won't split/splinter). I've read of wood dowels splintering in the bore and wedging in between the bullet and barrel getting stuck pretty hard. I keep a 12" rod in my range box and when I shoot a rifle I have one 36" long that I take along...

I bought one of these; 1/4"x6' which gave me a few "squib rods" for less than $15.00. https://www.mcmaster.com/#standard-brass-alloy-rods/=1671ghx

Clovishound

Blackhawk

Mus408 said:Bullet was an Xtreme copper plated and tapped out easy with wood dowel.

These have a slight knurled crimp groove and looked like a good crimp pressure on the bullet.

So I assume maybe light powder charge or a not so hot primer fire.

Could be just a plain mess up on my part with no powder..but the Dillon 550 press has a very positive

powder drop.

What is your powder charge verification routine? Visual, powder check die? If the answer is none, this will likely not be your last squib. Powder measures are very reliable, but they are not perfect, no matter who makes them. Not only that, but given the volume of ammo most of us make, the odds are that something unexpected will occur at some point. Sometimes it's the equipment that fails, usually it is the operator that is at fault.

I once had a .357 that showed up in the powder check die as overcharged. I dumped the charge, refilled and still over. I looked in the case and there was a lot of compressed powder stuck in the bottom of the case. My best guess was I had a .357 case mixed in with the .38s and discovered it when dropping powder/flaring. Thought I dumped the powder, but didn't and decapped the SP primer and dropped the case in the .357 ready to load. The shoulder of the decapping pin likely compressed the powder and made a cake that stuck in the case. I should have inspected the case before putting in the the other ready to load cases, but it had already been inspected once. Strike one. I should have dumped the powder before depriming, thought I had. Strike two. Had I not used a powder check die, it would have been strike three. A visual inspection of the powder charge would have caught this as well. As a result of this mistake, I have changed my case handling/inspection routine, but the powder check is the last line of defense.

On another note, I don't think a "not so hot primer fire" would result in a squib. If the primer fired enough to move the bullet out of the case, I can't help but think it would have ignited enough powder to move the bullet out of the barrel, if there was a normal powder charge in the case. Just my opinion.

I do visuals but not for every single round BUT WILL find away now to mount a small mirror in that

loading station of the press. It's a tight spot in there.

I also do many spot checks on the load weight using my balance scale or the digital scale.

loading station of the press. It's a tight spot in there.

I also do many spot checks on the load weight using my balance scale or the digital scale.

Clovishound

Blackhawk

Visuals are fine. I find that powder check dies are easier to use, and it's a lot easier to spot an over/under charge than eyeballing a single case, especially with deep cases like .38 and .357. Having said that, the important thing is to identify a large deviation. Of course the thing with a powder check die, unless it is a lock out or audible warning style, is that you must look at it every time you pull the handle on a charged case. The same is true with a visual inspection. IMO EVERY round must be checked for a gross deviation. Checking 25% of them, just reduces the chances of a squib/overload by 25%. Spot weighings are necessary, but they are designed to make sure your measure isn't drifting.

Do you have room for a powder check die? FWIW, I use a powder cop die for my deep cases, and a visual for my shallow auto cases. I only have 4 stations on my turret, and prefer to seat and crimp separately when possible. I feel that the visual I get with, say 9mm, cases is sufficient to identify problem charges. With deep cases and charges being a small percentage of case volume, I use the powder check, even if it means having to size/decap in a separate operation. Bottleneck rifle calibers have every charge weighed and then visually inspected prior to seating a bullet. Of course, they are low production numbers for rifle calibers, and I drop powder for them using a stand alone measure vs a die mounted for pistol calibers.

Do you have room for a powder check die? FWIW, I use a powder cop die for my deep cases, and a visual for my shallow auto cases. I only have 4 stations on my turret, and prefer to seat and crimp separately when possible. I feel that the visual I get with, say 9mm, cases is sufficient to identify problem charges. With deep cases and charges being a small percentage of case volume, I use the powder check, even if it means having to size/decap in a separate operation. Bottleneck rifle calibers have every charge weighed and then visually inspected prior to seating a bullet. Of course, they are low production numbers for rifle calibers, and I drop powder for them using a stand alone measure vs a die mounted for pistol calibers.

My press is the Dillon 550B with 4 stations.

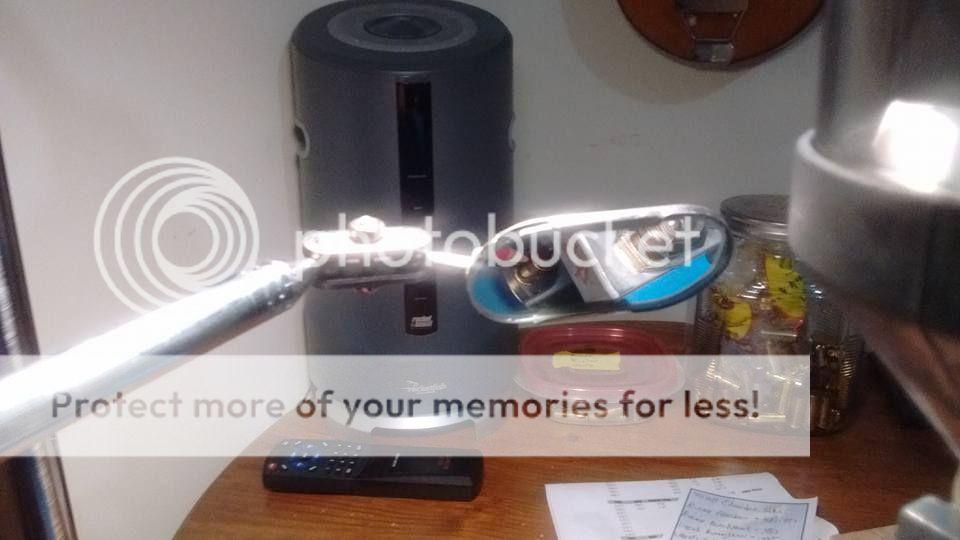

I just found a way to mount a small mirror which is fully adjustable.

If you look close at the red pencil pointing at the .45 Colt case you may see the shiny bottom.

Looks better in person. This will be of great help for easy visual from my seated position while loading.

I just found a way to mount a small mirror which is fully adjustable.

If you look close at the red pencil pointing at the .45 Colt case you may see the shiny bottom.

Looks better in person. This will be of great help for easy visual from my seated position while loading.

Similar threads

- Replies

- 17

- Views

- 574

- Replies

- 3

- Views

- 225

- Replies

- 4

- Views

- 344