Shooting cast bullets in the 480 Ruger can have some problems. SAAMI specs (and Ruger) call for a rather abrupt 45 degree step which transitions into the cylinder throats. This can cause the chambers to shave off a "ring" of lead from the bullets as they are fired, and after a few rounds, will prevent chambering of fresh ammo.

To cure the problem, I had Clyde at Manson Reamers make me a custom finishing reamer on my own specs with the more typical 6 degree 30min angle so that the chamber will have a more traditional chamfer and facilitate the use of cast bullets without ringing the chambers..

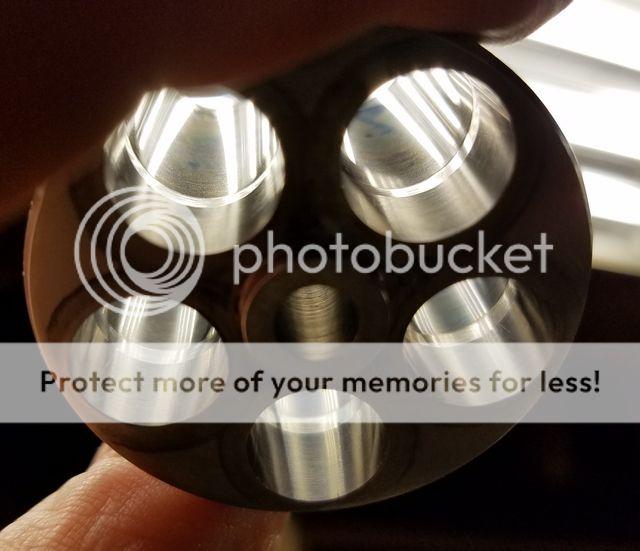

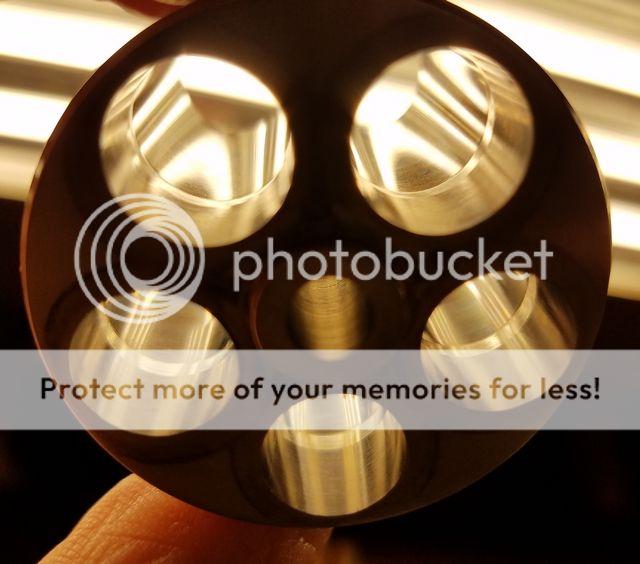

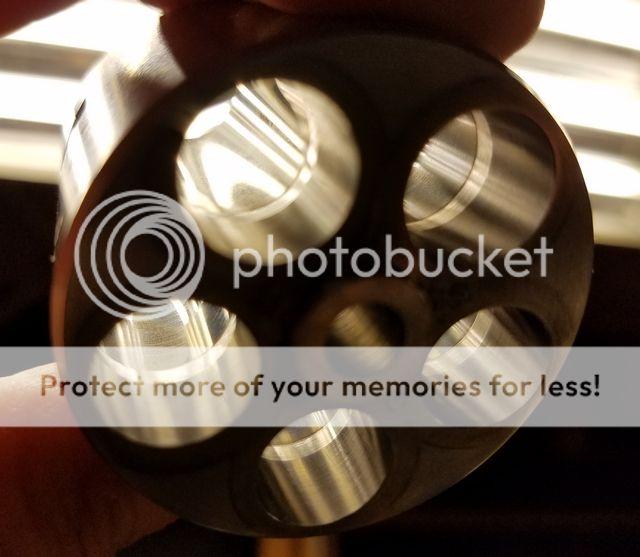

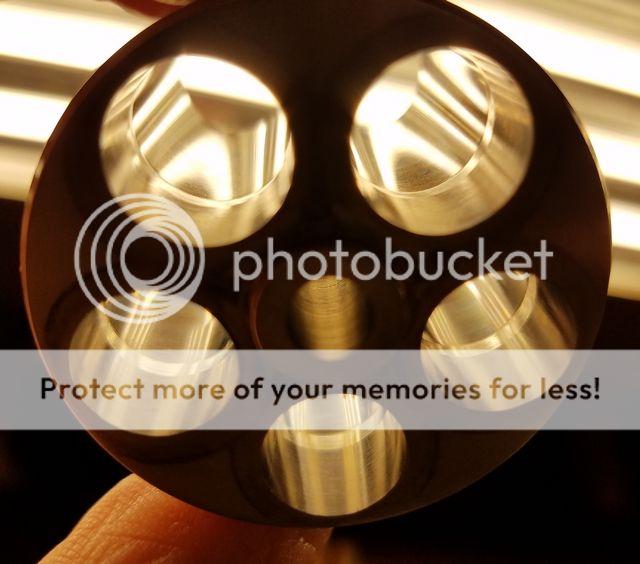

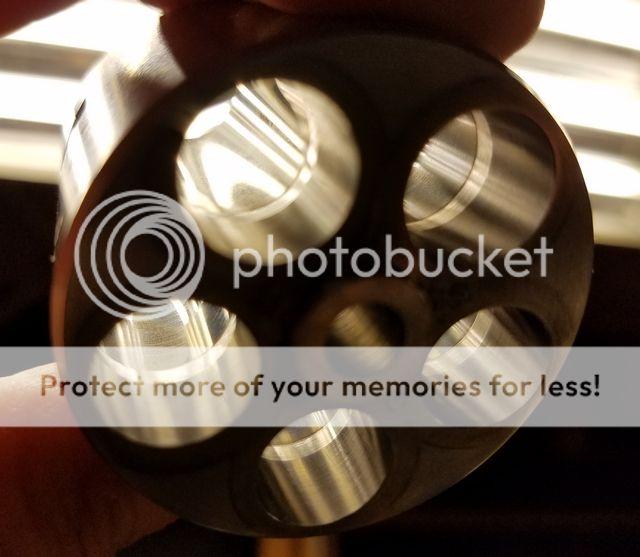

Here are some pics. You can see in the first pic, a stock 480 Ruger cylinder with the very abrupt angle, the rest of the pics are this same cylinder after reaming the chambers to remove that sharp angle and change it into a much easier transition from case mouth to cylinder throat..

BTW, the throats in front of the chamfers were honed with the Sunnen hone to make them a consistent .4782" so I could use a .478" pilot on the nose of the reamer. This insures the chamfer is concentric to the throat. You want the tightest fit you can achieve with the pilot for the best results.

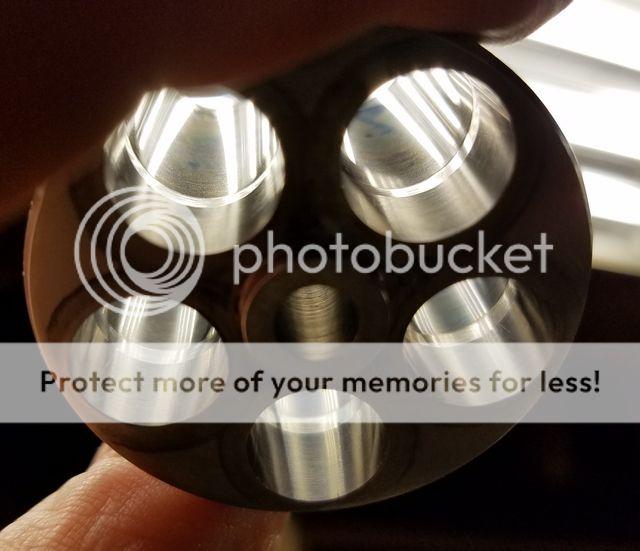

The last pic is a dead stop that I machined from tool steel to insure consistent depth and conformity.

To cure the problem, I had Clyde at Manson Reamers make me a custom finishing reamer on my own specs with the more typical 6 degree 30min angle so that the chamber will have a more traditional chamfer and facilitate the use of cast bullets without ringing the chambers..

Here are some pics. You can see in the first pic, a stock 480 Ruger cylinder with the very abrupt angle, the rest of the pics are this same cylinder after reaming the chambers to remove that sharp angle and change it into a much easier transition from case mouth to cylinder throat..

BTW, the throats in front of the chamfers were honed with the Sunnen hone to make them a consistent .4782" so I could use a .478" pilot on the nose of the reamer. This insures the chamfer is concentric to the throat. You want the tightest fit you can achieve with the pilot for the best results.

The last pic is a dead stop that I machined from tool steel to insure consistent depth and conformity.