TionestaDoug

Bearcat

- Joined

- Feb 1, 2016

- Messages

- 12

I have tried to adjust for all the dies trying to get the dies in time and as soon as I get one in time the others are off. Any thoughts?

6gun said:You get what you pay for toss it and buy a RCBS.

Clovishound said:6gun said:You get what you pay for toss it and buy a RCBS.

I also have loaded thousands and thousands of rounds on my LCT. IMO it is a quality machine. Like any rotating press, it needs some occasional maintenance. Cleaning, lubing, and yes, the little sacrificial part has to be replaced every few years, or whenever the mechanism has been "forced". That is why it's made of plastic.

RCBS makes good stuff. The LCT is a good press as well, at a different price point.

Clark said:I love my Lee turret press. I should buy some of those plastic gizmos to have on hand but it will probably take learning the hard way to do that...

6gun - Thanks for your enlightened opinion, if it hasn't been made clear then let me restate it for you: take it elsewhere.

Clark

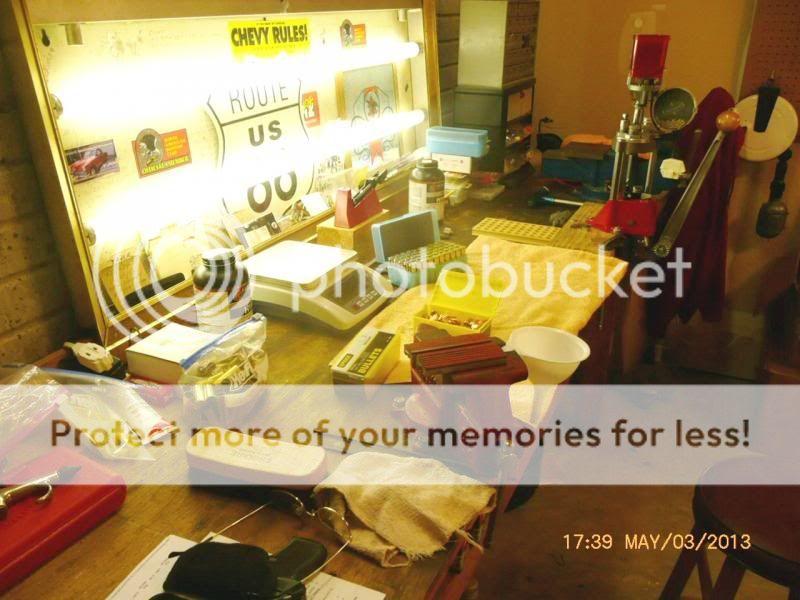

Mobuck said:Wow, my reloading bench hasn't been that clean since 3 hours after I finished building it.