P94/GP100

Single-Sixer

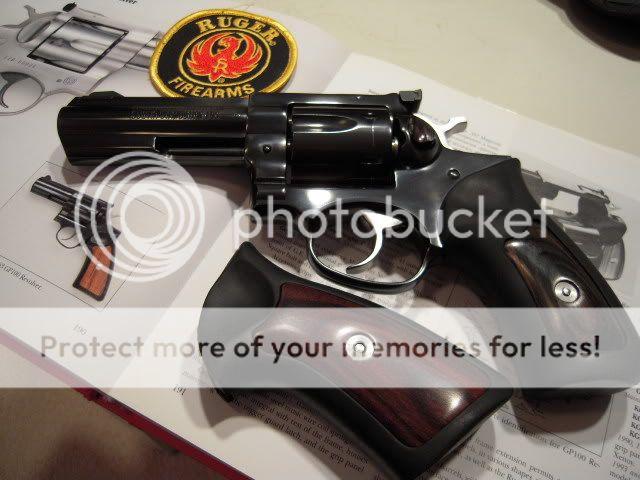

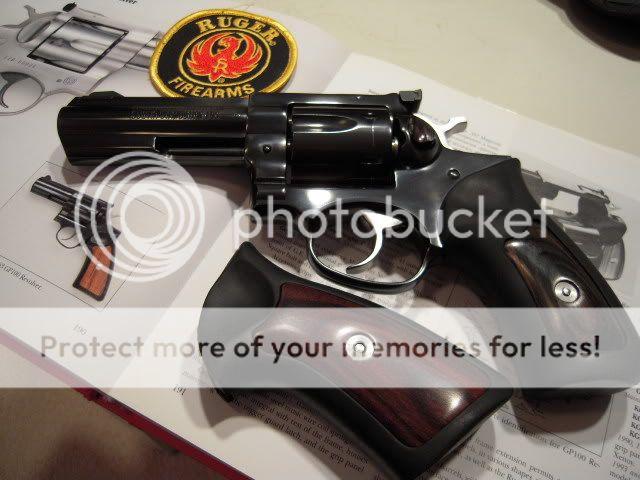

Attached are some images I thought forum participants might enjoy of my 1998 vintage 173-serial number GP100, which I bought specifically with the intention of having Chris Peters thoroughly go through. The work was inspired by a 1992 Massad Ayoob article, where he thoroughly discussed Chris' GP100 gunsmithing skills and results. I kept the article in the back of my mind, and 1998 proved to be an opportune time to have the project done. Chris' extracurricular efforts at the time (he was concurrently a full-time Ruger employee; he subsequently retired, and then was re-hired at Ruger's behest as head of their New Hampshire Customer Service Department, which I believe is his current position at Ruger) were through Wind River Trading Company, headed by Skip Christie. Skip, Chris and I thoroughly discussed my project; my goal was to have the revolver optimized for both carry and steel plate competition(that being my primary competition venue at the time-it's since switched to IDPA).

Starting with a GP100 package Chris and Skip termed the Lynx (which was what Massad had used and reviewed), we meticulously went through what would work best for me. Ultimately, the project involved a complete action job, recutting the forcing cone, recutting/bevelling the muzzle, chamfering the cylinder charge holes, deburring/polishing the chambers, deburring the ejector pins, replacing the OEM ejector with a modified one, which Chris developed and termed the "+P Power Eater," with a terraced front face designed to preclude unburnt powder granules and residue (particularly prevelant with +P ammunition) from wedging between the cylinder's back face and the ejector, potentially tying up the cylinder, polishing the ejector rod, rounding and polishing the trigger, replacing the front sight with Millett's Orange Bar sight, and the rear sight with Millett's White Outline sight (sadly, Millett has pretty much totally eliminated their iron sight offerings a year or so back), peening of both the cylinder latch pin and rear sight retaining pin, providing a Lett Winewood laminate insert for the larger grip, and a Lett Silver-Black laminate insert for the compact grip (the larger grip is intended for heavier recoiling .357 magnum loads, while the compact grips are optimized for carry/competition, where I usually use 125 grain .38 Special +P loadings-the compact grip handles beautifully, without compromising the grip in the least). Externally, Chris provided his intermediate-level polish and bright blueing, with the topstrap bead-blasted for a non-reflective matte blue (the result was magnificent; if this is his intermediate level, his "ultimate" level could only be incrimentally better to my visualization).

Additionally, as Chris was unsatisfied with the OEM cylinder and barrel, he facilitated Ruger replacing them both under warranty in conjunction with the project.

Upon receipt of the gun, I had Kramer make up one of their horsehide IWB holsters for it for concealed carry/IDPA use, and I also obtained a Bianchi UM84R full flap holster for hiking/hunting/field use (that's the revolver version for their military M12 holster).

For carry, I normally use Remington's 125 gr .38 Special +P Golden Saber jacketed hollowpoint cartridges; as a less-expensive analog cartridge for competition and practice I normally use Remington/UMC's 125 gr .38 Special +P semi-jacketed hollowpoints. For IDPA, I normally administratively load the cylinder with a Bianchi Speed Strip (as in normal carry a Speed Strip carried in a upsidedown Galco 2X2X2 pouch positioned on my strongside, immediately in front of the holster for a back-up reload); subesquent reloads are accomplished with a Safariland Comp III speedloader carried loose in my strongside vest/jacket pocket (as I normally do "in real life"); additional IDPA reloads are accomplished with 2 HKS Speedloaders carried in a velcro-flapped Bianchi Accumold Dual Speedloader Pouch carried directly in front of the holster.

Despite the extensive custom work, the revolver is in full compliance with IDPA's Stock Service Revolver criteria, so I compete in that division with the revolver.

For lubrication, internal action lubrication is achieved with Dri-Slide, a molybednum disulfide dry-film lubricant carried in suspension in a liquid carrier solution (after application, where capillary action serves to effectively deposit the solution to all the action's nooks and crannies, the liquid solution evaporates, leaving a non-residue attracting dry film application of lubricant that I've found particularly ideal for revolver actions over the years). The hammer pin axle was lubricated with a coat of TW25B, as were the cylinder crane/frame pivot interface points. A drop of Weapon Shield was provided as lubricant for cylinder rotation around the crane shaft, applied at the front face of the cylinder, and a light coat of Weapon Shield was applied a a general anti-corrosive to the exterior.

Enjoy!

Best, Jon

Starting with a GP100 package Chris and Skip termed the Lynx (which was what Massad had used and reviewed), we meticulously went through what would work best for me. Ultimately, the project involved a complete action job, recutting the forcing cone, recutting/bevelling the muzzle, chamfering the cylinder charge holes, deburring/polishing the chambers, deburring the ejector pins, replacing the OEM ejector with a modified one, which Chris developed and termed the "+P Power Eater," with a terraced front face designed to preclude unburnt powder granules and residue (particularly prevelant with +P ammunition) from wedging between the cylinder's back face and the ejector, potentially tying up the cylinder, polishing the ejector rod, rounding and polishing the trigger, replacing the front sight with Millett's Orange Bar sight, and the rear sight with Millett's White Outline sight (sadly, Millett has pretty much totally eliminated their iron sight offerings a year or so back), peening of both the cylinder latch pin and rear sight retaining pin, providing a Lett Winewood laminate insert for the larger grip, and a Lett Silver-Black laminate insert for the compact grip (the larger grip is intended for heavier recoiling .357 magnum loads, while the compact grips are optimized for carry/competition, where I usually use 125 grain .38 Special +P loadings-the compact grip handles beautifully, without compromising the grip in the least). Externally, Chris provided his intermediate-level polish and bright blueing, with the topstrap bead-blasted for a non-reflective matte blue (the result was magnificent; if this is his intermediate level, his "ultimate" level could only be incrimentally better to my visualization).

Additionally, as Chris was unsatisfied with the OEM cylinder and barrel, he facilitated Ruger replacing them both under warranty in conjunction with the project.

Upon receipt of the gun, I had Kramer make up one of their horsehide IWB holsters for it for concealed carry/IDPA use, and I also obtained a Bianchi UM84R full flap holster for hiking/hunting/field use (that's the revolver version for their military M12 holster).

For carry, I normally use Remington's 125 gr .38 Special +P Golden Saber jacketed hollowpoint cartridges; as a less-expensive analog cartridge for competition and practice I normally use Remington/UMC's 125 gr .38 Special +P semi-jacketed hollowpoints. For IDPA, I normally administratively load the cylinder with a Bianchi Speed Strip (as in normal carry a Speed Strip carried in a upsidedown Galco 2X2X2 pouch positioned on my strongside, immediately in front of the holster for a back-up reload); subesquent reloads are accomplished with a Safariland Comp III speedloader carried loose in my strongside vest/jacket pocket (as I normally do "in real life"); additional IDPA reloads are accomplished with 2 HKS Speedloaders carried in a velcro-flapped Bianchi Accumold Dual Speedloader Pouch carried directly in front of the holster.

Despite the extensive custom work, the revolver is in full compliance with IDPA's Stock Service Revolver criteria, so I compete in that division with the revolver.

For lubrication, internal action lubrication is achieved with Dri-Slide, a molybednum disulfide dry-film lubricant carried in suspension in a liquid carrier solution (after application, where capillary action serves to effectively deposit the solution to all the action's nooks and crannies, the liquid solution evaporates, leaving a non-residue attracting dry film application of lubricant that I've found particularly ideal for revolver actions over the years). The hammer pin axle was lubricated with a coat of TW25B, as were the cylinder crane/frame pivot interface points. A drop of Weapon Shield was provided as lubricant for cylinder rotation around the crane shaft, applied at the front face of the cylinder, and a light coat of Weapon Shield was applied a a general anti-corrosive to the exterior.

Enjoy!

Best, Jon