In diagnosing feed/return to battery problems...once the magazine is eliminated as a possible cause...the next thing to look at is the extractor. We're assuming that the critical dimensions and geometry is within spec, and the pistol hasn't suffered the attentions of Dremel Dan and his typical work on the feed ramps.

The extractor's task is to pull the fired case from the chamber and hold onto it long enough for it to hit the ejector. That requires that the extractor place a little tension on the side of the rim and maintain it long enough to last the short trip. Much is made of proper extractor tension, with several knowledgeable people insisting on a narrow range. Too much and the slide can fail to return to battery. Too little, and the case falls off the breechface before it hits the ejector, causing weak and/or erratic ejection...or an outright failure to eject.

I haven't found that such a narrow window is all that critical, and that the gun will tolerate a lot more tension provided that the extractor operates with the proper amount of deflection...or lateral displacement with the case rim in place.

It doesn't take a lot of deflection, and too many modern pistols have way yonder more than necessary. If the case rim springs the extractor open as little as .005 inch...that's enough if the tension is sufficient. I like to see about .010-.012 inch, with .015 as a maximum...but I've gotten by with less.

There's another dimension involved. The distance between the breechface guide blocks. These are the two small, rectangular projections on the underside of the breechface. The extractor passes through one of them. Deflection is determined by the amount of the extractor's tensioning wall that protrudes past its block. Too much, and the rim literally hits a wall as it slides up the breechface and it can bring the slide to a stop just short of full battery. Too little, and we get extraction and/or ejection problems. By a wide margin, I've found too much in a good many production guns, and only rarely too little.

The wall protrusion is determined by the dimension of the forward pad, just behind the claw. If that is within spec at around .130-inch thick...and the breechface guides are within spec and centered...and the extractor channel isn't angled...the extractor will drop in and work with just a little bending for proper tension. If any of these dimensions are out of spec...it probably won't. You can bend and straighten the extractor until pigs fly and still have as problem on one function or the other.

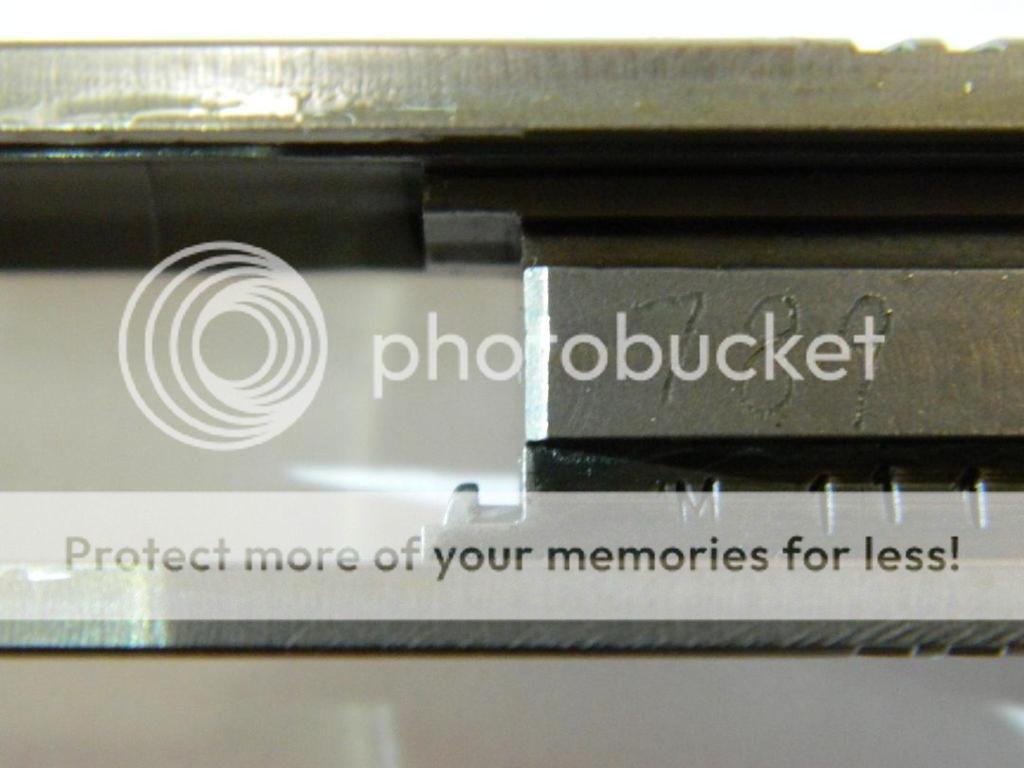

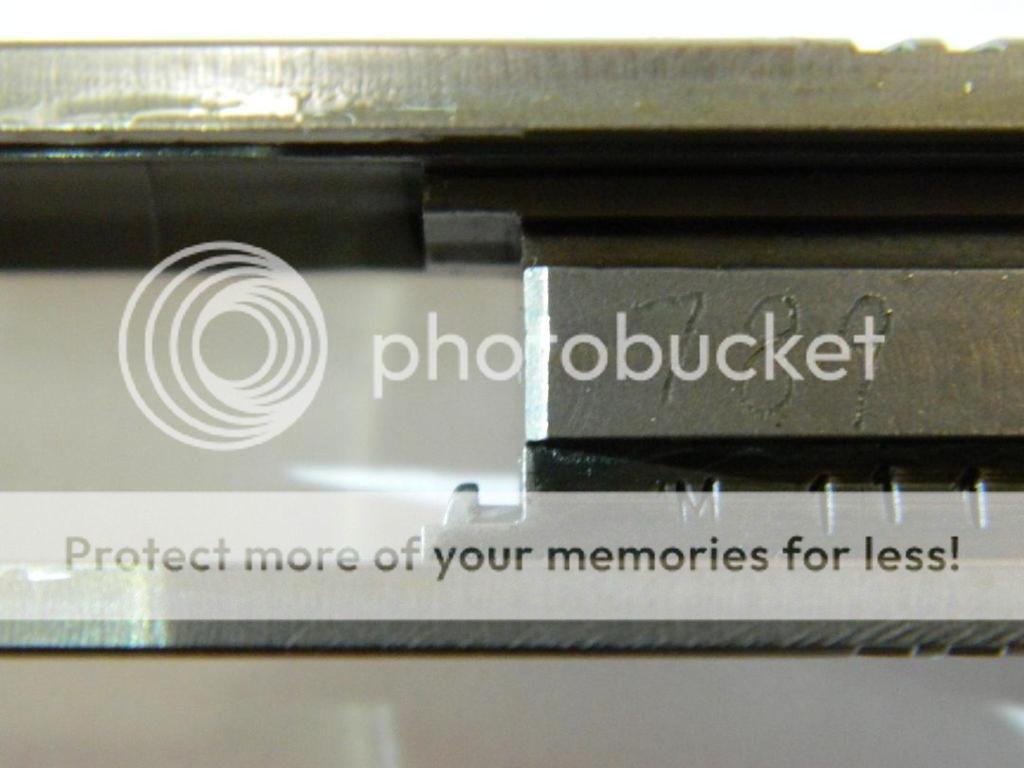

On the next post, we'll look at the guide blocks and how they figure into this. Meanwhile, the picture below shows a condition of wayyyy yonder too much deflection. This one was driving the owner 'round the bend with intermittent failures to go to battery, which is most often seen with deflection like this...but it can also cause a nose-dive into the ramp, even with good magazines and all critical dimensions within spec.

In other words, it can mimic a magazine problem, and is probably responsible for more Bubba-ed up feed and barrel ramps than anything else, because even Bubba usually tries different magazines before reaching for his Dremel tool.

Look at the picture. If you're having frequent return to battery failures, and you've tried different magazines without much success...this is the next place to look. Chances are, this is what you'll find. This was an OEM extractor in a good quality production gun. It had been back to the factory without resolve. The fix took all of about 10 minutes.

So, study this picture for a few minutes and visualize how it can cause a problem. I'll touch on the guide block specs later.

The extractor's task is to pull the fired case from the chamber and hold onto it long enough for it to hit the ejector. That requires that the extractor place a little tension on the side of the rim and maintain it long enough to last the short trip. Much is made of proper extractor tension, with several knowledgeable people insisting on a narrow range. Too much and the slide can fail to return to battery. Too little, and the case falls off the breechface before it hits the ejector, causing weak and/or erratic ejection...or an outright failure to eject.

I haven't found that such a narrow window is all that critical, and that the gun will tolerate a lot more tension provided that the extractor operates with the proper amount of deflection...or lateral displacement with the case rim in place.

It doesn't take a lot of deflection, and too many modern pistols have way yonder more than necessary. If the case rim springs the extractor open as little as .005 inch...that's enough if the tension is sufficient. I like to see about .010-.012 inch, with .015 as a maximum...but I've gotten by with less.

There's another dimension involved. The distance between the breechface guide blocks. These are the two small, rectangular projections on the underside of the breechface. The extractor passes through one of them. Deflection is determined by the amount of the extractor's tensioning wall that protrudes past its block. Too much, and the rim literally hits a wall as it slides up the breechface and it can bring the slide to a stop just short of full battery. Too little, and we get extraction and/or ejection problems. By a wide margin, I've found too much in a good many production guns, and only rarely too little.

The wall protrusion is determined by the dimension of the forward pad, just behind the claw. If that is within spec at around .130-inch thick...and the breechface guides are within spec and centered...and the extractor channel isn't angled...the extractor will drop in and work with just a little bending for proper tension. If any of these dimensions are out of spec...it probably won't. You can bend and straighten the extractor until pigs fly and still have as problem on one function or the other.

On the next post, we'll look at the guide blocks and how they figure into this. Meanwhile, the picture below shows a condition of wayyyy yonder too much deflection. This one was driving the owner 'round the bend with intermittent failures to go to battery, which is most often seen with deflection like this...but it can also cause a nose-dive into the ramp, even with good magazines and all critical dimensions within spec.

In other words, it can mimic a magazine problem, and is probably responsible for more Bubba-ed up feed and barrel ramps than anything else, because even Bubba usually tries different magazines before reaching for his Dremel tool.

Look at the picture. If you're having frequent return to battery failures, and you've tried different magazines without much success...this is the next place to look. Chances are, this is what you'll find. This was an OEM extractor in a good quality production gun. It had been back to the factory without resolve. The fix took all of about 10 minutes.

So, study this picture for a few minutes and visualize how it can cause a problem. I'll touch on the guide block specs later.