A topic that's probably discussed more often than any other, and a question that's usually asked more. "Which magazine is best?"

The 1911 has earned a reputation in many circles for being a "finicky" feeder, often requiring just the right combination of magazine and ammunition in order to be reliable. I first heard of it about 30 years ago, and I was a little puzzled. I wondered what had happened. I'd never known the pistol to be fussy about ammunition, other than the occasional burp with certain hollowpoints. Namely, the old Hydra Shok ™ and Speer's 200-grain "Flying Ashtray" and both of those were doable by opening up the barrel ramp...or "throat" as it's become incorrectly called.

In the dear, dead days before its resurgence in popularity, the only magazines available were the same ones that had been designed by John Browning and Colt's Dream Team of top engineers...and those magazines that came in the box with Colt's pistols up until the early 80s all worked in pistols dating from 1912 forward. They often required modification to the lips in order to feed the semiwadcutters preferred by Bullseye competitors, but all that consisted of was forming a timed release point. Behind the release, they functioned exactly the same...modified or not. At one time...when I was doin' the job...I had the die and anvil set to modify the Hardball feed lips for the guys who wanted to use SWC ammunition, and the recent arrival of hollowpoints when needed...and they didn't always need it.

Then, around 1982 or 83....Colt made the tool obsolete when they quietly modified the feed lip design and gave us what I came refer to as the "Hybrid" feed lips. They combined the gradual, controlled rise of the hardball magazine with the earlier release point of the Bullseye/SWC modification, and their magazines worked well across the board with all sorts of ammunition as long as the proper barrel ramp cut was included.

Incidentally, that "throated" ramp came about because of SWC bullets...not hollowpoints. More on that later.

Then, just a few years later...the 1911 became finicky, and my response was: "Now what?"

I noticed that some of the aftermarket magazines had different feed lips. The taper so carefully worked out by the genius was gone...and the complaints rose. Many people lamented the feed angle, stating that what was needed was a straight approach to the chamber. The problem with that was that a straight shot into the chamber was hard to arrange because it would force the extractor to climb over the case rim...and that was a no-no. The rim had to get behind the extractor from underneath.

Then they started working to make the feed angle less abrupt by trying to place the round as high as possible in the feeding position and radiusing the bottom corner of the extractor claw for clearance. Then came mirror polishing the feed ramp and rounding the top corner of the barrel ramp, which...if taken too far...resulted in the case being unsupported.

All in order to reduce the feed angle and get the pistols to run. One noted pistol smith/builder/marketer of high end semi- customs made the statement that the toughest bullet profile to get a 1911 reliably feed with was...are you sitting down...hardball. I was like...lolWUT?

So, now the problem was the acute angle of approach after bouncing off the feed ramp, and the lament that this angle made the 1911 finicky and it required the attentions of a skilled smith before it could ever be reliable enough for serious business.

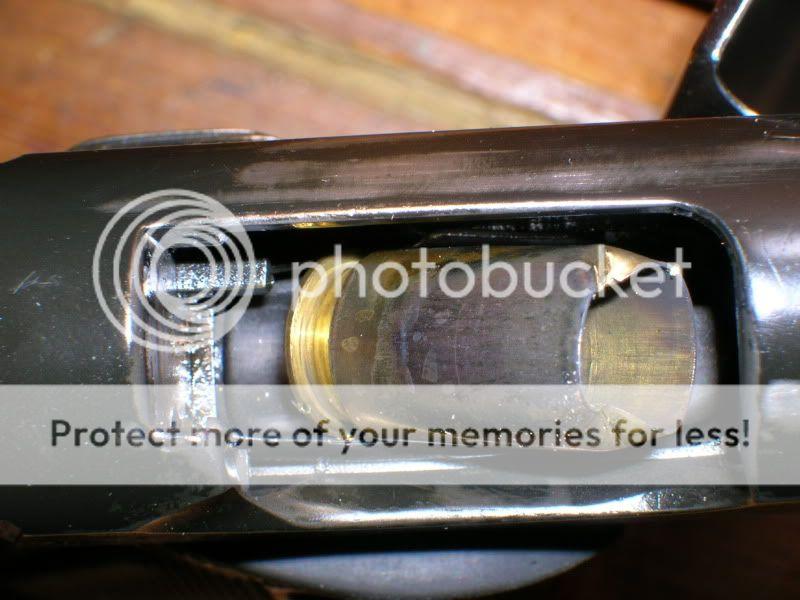

Study the picture below. It illustrates the difference between the parallel feed lips and the tapered feed lips, and the positioning of the cartridge just before the final release point...and we come to understand that Browning was well aware of the angle and the potential problems associated with it...and we can see that the solution was there all along if someone had just taken the time to look at it.

And finally someone did. Either that, or it's proof that some of these folks do surf the forums and are open to suggestions. It's come to my attention that the same renowned smith/builder/marketer has started offering his flagship magazines with...tapered feed lips and a timed release point.

Look and learn. This is the way that the 1911 is supposed to feed...with the rim under the extractor before the magazine releases it. Smooth, controlled feed with a low angle into the chamber. Browning really did have the answer.

It's ironic...and a little amusing...that everyone pretty well accepts that the 1911 has to closely adhere to spec in order to function reliably...but somehow feel that doesn't apply to the magazine, and that they can modify part of the system without consequence. Controlled feed is a system, and the magazine is part of that system. A firearms design genius...along with a team of very sharp engineers...worked the bugs out of that system over a hundred years ago.

Study it, and think carefully about what you're seeing.

The 1911 has earned a reputation in many circles for being a "finicky" feeder, often requiring just the right combination of magazine and ammunition in order to be reliable. I first heard of it about 30 years ago, and I was a little puzzled. I wondered what had happened. I'd never known the pistol to be fussy about ammunition, other than the occasional burp with certain hollowpoints. Namely, the old Hydra Shok ™ and Speer's 200-grain "Flying Ashtray" and both of those were doable by opening up the barrel ramp...or "throat" as it's become incorrectly called.

In the dear, dead days before its resurgence in popularity, the only magazines available were the same ones that had been designed by John Browning and Colt's Dream Team of top engineers...and those magazines that came in the box with Colt's pistols up until the early 80s all worked in pistols dating from 1912 forward. They often required modification to the lips in order to feed the semiwadcutters preferred by Bullseye competitors, but all that consisted of was forming a timed release point. Behind the release, they functioned exactly the same...modified or not. At one time...when I was doin' the job...I had the die and anvil set to modify the Hardball feed lips for the guys who wanted to use SWC ammunition, and the recent arrival of hollowpoints when needed...and they didn't always need it.

Then, around 1982 or 83....Colt made the tool obsolete when they quietly modified the feed lip design and gave us what I came refer to as the "Hybrid" feed lips. They combined the gradual, controlled rise of the hardball magazine with the earlier release point of the Bullseye/SWC modification, and their magazines worked well across the board with all sorts of ammunition as long as the proper barrel ramp cut was included.

Incidentally, that "throated" ramp came about because of SWC bullets...not hollowpoints. More on that later.

Then, just a few years later...the 1911 became finicky, and my response was: "Now what?"

I noticed that some of the aftermarket magazines had different feed lips. The taper so carefully worked out by the genius was gone...and the complaints rose. Many people lamented the feed angle, stating that what was needed was a straight approach to the chamber. The problem with that was that a straight shot into the chamber was hard to arrange because it would force the extractor to climb over the case rim...and that was a no-no. The rim had to get behind the extractor from underneath.

Then they started working to make the feed angle less abrupt by trying to place the round as high as possible in the feeding position and radiusing the bottom corner of the extractor claw for clearance. Then came mirror polishing the feed ramp and rounding the top corner of the barrel ramp, which...if taken too far...resulted in the case being unsupported.

All in order to reduce the feed angle and get the pistols to run. One noted pistol smith/builder/marketer of high end semi- customs made the statement that the toughest bullet profile to get a 1911 reliably feed with was...are you sitting down...hardball. I was like...lolWUT?

So, now the problem was the acute angle of approach after bouncing off the feed ramp, and the lament that this angle made the 1911 finicky and it required the attentions of a skilled smith before it could ever be reliable enough for serious business.

Study the picture below. It illustrates the difference between the parallel feed lips and the tapered feed lips, and the positioning of the cartridge just before the final release point...and we come to understand that Browning was well aware of the angle and the potential problems associated with it...and we can see that the solution was there all along if someone had just taken the time to look at it.

And finally someone did. Either that, or it's proof that some of these folks do surf the forums and are open to suggestions. It's come to my attention that the same renowned smith/builder/marketer has started offering his flagship magazines with...tapered feed lips and a timed release point.

Look and learn. This is the way that the 1911 is supposed to feed...with the rim under the extractor before the magazine releases it. Smooth, controlled feed with a low angle into the chamber. Browning really did have the answer.

It's ironic...and a little amusing...that everyone pretty well accepts that the 1911 has to closely adhere to spec in order to function reliably...but somehow feel that doesn't apply to the magazine, and that they can modify part of the system without consequence. Controlled feed is a system, and the magazine is part of that system. A firearms design genius...along with a team of very sharp engineers...worked the bugs out of that system over a hundred years ago.

Study it, and think carefully about what you're seeing.