As noted above,, it's actually not very hard to do.

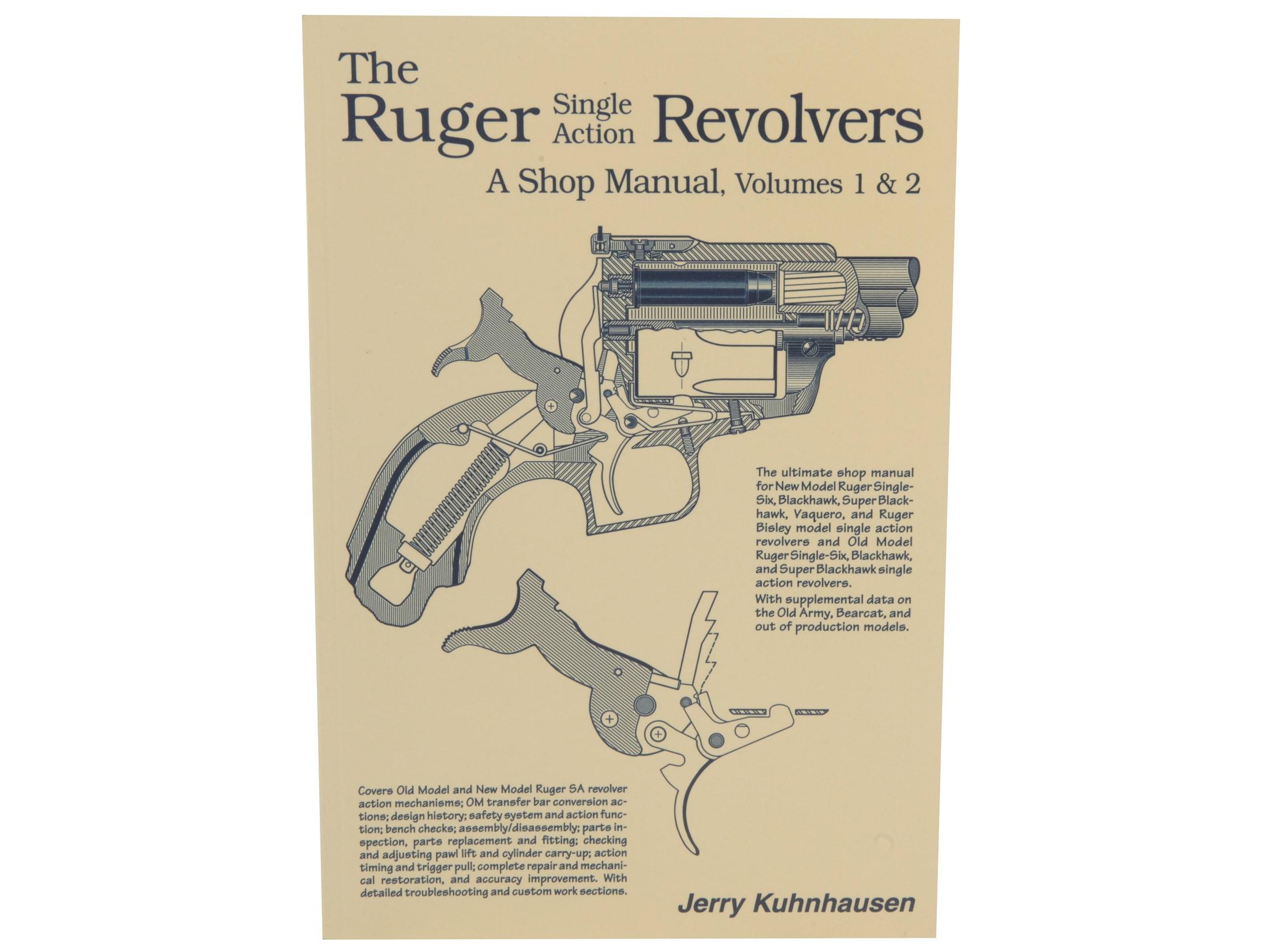

The best thing is to get a correct manual and it shows how to disassemble & reassemble the gun. And if you don't have a manual, Ruger sends reprints out, for free, or heck, I'm sure I could dig a reprint out for you. (If I haven't given them all away or lost them in the mess of my stuff.)

One VERY important step; USE CORRECTLY FITTING SCREWDRIVERS to avoid marring the gun, the screws etc.

From memory;

Remove the grips.

Cock the hammer.

Insert a pin in the mainspring strut bottom, to capture the spring under tension.

Pull the trigger, and you will have a "floppy" hammer, as the mainspring is now removed from the hammer.

Remove the (5) screws holding the grip frame from the main frame.

Remove the g/f & mainspring assy from the frame.

The 3 screws in the side of the main frame hold the trigger, the hammer & all in place in the frame. Remove them, and the parts will easily come out. Pay attention to the way the parts come out, and just reverse the procedure to re-install the replacement parts.

You can check operation by manually operating it all together once reassembled w/o the g/f & all. Just realize that the hammer doesn't have anything to move it. Do so manually. Once you have the internals replaced, and they move as they should, you can re-install the grip frame & mainspring assy.

Cock & remove the capture pin, and if all was done correctly, it'll operate just fine. Put the grips back on.

A manual has this info as well, and shows the parts etc. Having a manual would be very helpful.