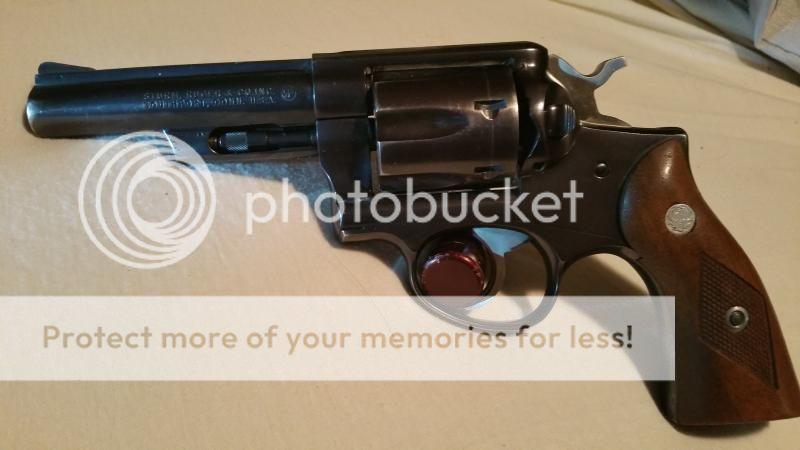

I've been taking a hiatus from RF for a while, but not from shooting or hand loading.

For anyone here who reloads or casts for the .357mag/38 special the 358156 bullet might be a great all around bullet for your needs. It's what I find myself using for most of my 357 needs, and even some of my 38 special needs (I have a version of this mold that drops a bullet with a plain base) My molds can drop this bullet with a flat point, the penta point that really is not that deep of a cavity, or with a DEEP hollow point spud.

The bullets tested were with an alloy of wheel weights +2% tin air cooled and sized to .359 (as the same alloy sized to .358 tended to lead my revolvers barrel). The bullets are 151 grains after they are sized, lubed and gas checked. The lubricant is bees wax, lard, Johnson's paste wax and enough Vaseline to make it sticky and flow nicely through the lube sizer.

There was no leading in my revolver, or my Marlin 1894. Everything below 1200 ft/sec only expanded to .40" with about 12-14" penetration, while the rounds between 1200-1300 ft/sec went between 14-16" and expanded to .50" diameter. The slower rounds could have benefited from a softer alloy or deeper hollow point, but would most certainly sacrifice on penetration. The bullet on the bottom of the picture below was traveling 1600 ft/sec from the 18" Marlin and penetrated 17", with a recovered diameter of .50" though it shed a lot of lead for a recovered weight of 114 grains.

Below are the results of this round with some jacketed bullets recovered from shredded rubber mulch. I KNOW… it's not ballistics gel; but it's cheap, reusable, and I find it to be a useful tool to compare bullet performance. Expansion in this media is not as consistent as it is with ballistics gel, as some bullets, such as the Barnes (top of picture at 1550 ft/sec), and the Federal HST (bullets in the middle of the picture) tend to get clogged with material… though I RARELY see the Barnes get clogged like the round pictured here. These 147 grain HST's were only hitting 930 ft/sec out of my M&P Shield, and perform much better than this when run through my full size CZ75B… which I did not have today. The 90 grain .380 FMJ on the middle far right and far left, fired out of my little Sig penetrated 16" lol

With this alloy/bullet/hollow point combination an impact velocity of 1200-1600 should give a nice balance of penetration and expansion. If I were using this bullet on pigs, I'd opt for a flat point. Here is my cheapo testing set up (until I get the time and refrigerator space to whip up some ballistics gel), if anyone is interested.

For anyone here who reloads or casts for the .357mag/38 special the 358156 bullet might be a great all around bullet for your needs. It's what I find myself using for most of my 357 needs, and even some of my 38 special needs (I have a version of this mold that drops a bullet with a plain base) My molds can drop this bullet with a flat point, the penta point that really is not that deep of a cavity, or with a DEEP hollow point spud.

The bullets tested were with an alloy of wheel weights +2% tin air cooled and sized to .359 (as the same alloy sized to .358 tended to lead my revolvers barrel). The bullets are 151 grains after they are sized, lubed and gas checked. The lubricant is bees wax, lard, Johnson's paste wax and enough Vaseline to make it sticky and flow nicely through the lube sizer.

There was no leading in my revolver, or my Marlin 1894. Everything below 1200 ft/sec only expanded to .40" with about 12-14" penetration, while the rounds between 1200-1300 ft/sec went between 14-16" and expanded to .50" diameter. The slower rounds could have benefited from a softer alloy or deeper hollow point, but would most certainly sacrifice on penetration. The bullet on the bottom of the picture below was traveling 1600 ft/sec from the 18" Marlin and penetrated 17", with a recovered diameter of .50" though it shed a lot of lead for a recovered weight of 114 grains.

Below are the results of this round with some jacketed bullets recovered from shredded rubber mulch. I KNOW… it's not ballistics gel; but it's cheap, reusable, and I find it to be a useful tool to compare bullet performance. Expansion in this media is not as consistent as it is with ballistics gel, as some bullets, such as the Barnes (top of picture at 1550 ft/sec), and the Federal HST (bullets in the middle of the picture) tend to get clogged with material… though I RARELY see the Barnes get clogged like the round pictured here. These 147 grain HST's were only hitting 930 ft/sec out of my M&P Shield, and perform much better than this when run through my full size CZ75B… which I did not have today. The 90 grain .380 FMJ on the middle far right and far left, fired out of my little Sig penetrated 16" lol

With this alloy/bullet/hollow point combination an impact velocity of 1200-1600 should give a nice balance of penetration and expansion. If I were using this bullet on pigs, I'd opt for a flat point. Here is my cheapo testing set up (until I get the time and refrigerator space to whip up some ballistics gel), if anyone is interested.