airfoil

Bearcat

Taking her apart was easy...putting it back together...we will see. But, I've got a hammer.

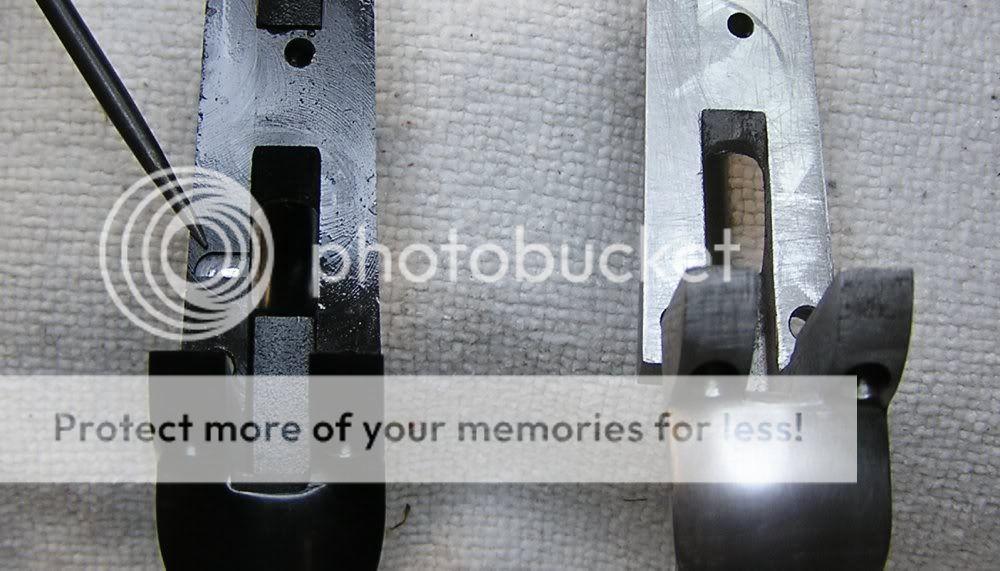

It's got that bottom lobe and the little divot in the frame...

[URL=http://s1362.photobucket.com/u...686/pf_airfoil/DSCN0280_zpsazgeecgh.jpg[/img][/url]

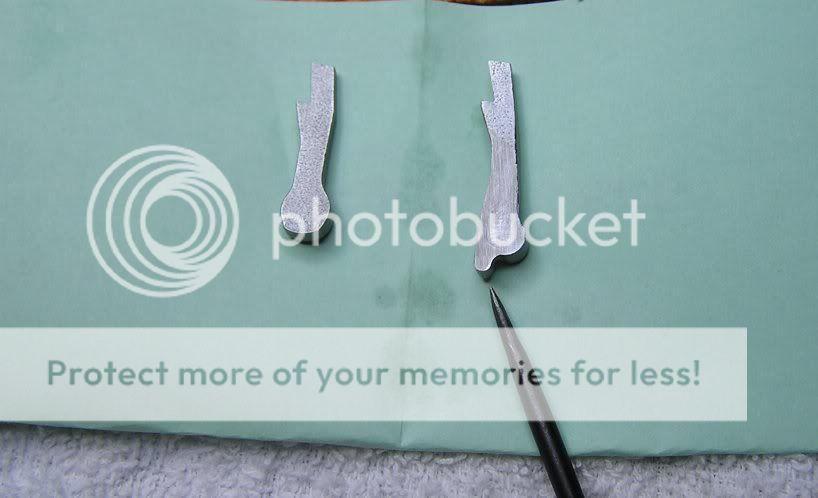

Looks like some wear and file marks...

[url=http://s1362.photobucket.com/u...686/pf_airfoil/DSCN0279_zpsmyf6osli.jpg[/img][/url]

[URL=http://s1362.photobucket.com/u...686/pf_airfoil/DSCN0278_zps1uhndqan.jpg[/img][/url]

[URL=http://s1362.photobucket.com/u...686/pf_airfoil/DSCN0271_zpsaztiz5ak.jpg[/img][/url]

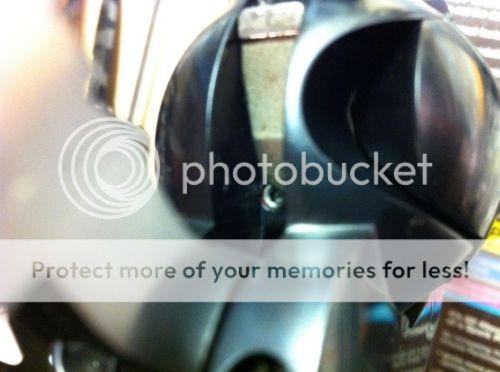

Scuffs on the hammer

The pawl is in good enough shape for measuring for fitting the new one, I trust...

I'm thinking it was a bad casting...I've fired this thing maybe 250 times and dry fired probably thrice that...I usually don't break my toys.

Might as well go ahead and polish up the trigger and hammer as outlined in this article...http://www.gunsamerica.com/blog/diy-slick-ruger-single-action/

The gate and cylinder latch felt fine to me, so won't do much with those.

When I get the replacements, I'll post. If anyone see's something amiss here, or want's me to take some more wedding pictures...chime in.

Thanks!

and please excuse my picture taking and posting to forum skillz

It's got that bottom lobe and the little divot in the frame...

[URL=http://s1362.photobucket.com/u...686/pf_airfoil/DSCN0280_zpsazgeecgh.jpg[/img][/url]

Looks like some wear and file marks...

[url=http://s1362.photobucket.com/u...686/pf_airfoil/DSCN0279_zpsmyf6osli.jpg[/img][/url]

[URL=http://s1362.photobucket.com/u...686/pf_airfoil/DSCN0278_zps1uhndqan.jpg[/img][/url]

[URL=http://s1362.photobucket.com/u...686/pf_airfoil/DSCN0271_zpsaztiz5ak.jpg[/img][/url]

Scuffs on the hammer

The pawl is in good enough shape for measuring for fitting the new one, I trust...

I'm thinking it was a bad casting...I've fired this thing maybe 250 times and dry fired probably thrice that...I usually don't break my toys.

Might as well go ahead and polish up the trigger and hammer as outlined in this article...http://www.gunsamerica.com/blog/diy-slick-ruger-single-action/

The gate and cylinder latch felt fine to me, so won't do much with those.

When I get the replacements, I'll post. If anyone see's something amiss here, or want's me to take some more wedding pictures...chime in.

Thanks!

and please excuse my picture taking and posting to forum skillz