tek4260

Buckeye

I finally got a second to try adding a stud between the ejector rod housing and the barrel to take the force off the screw when the revolver recoils. I didn't actually finish the project because the revolver I was going to try it on is an early NM therefore it already has a stud. I may finish this project later on a New Model that only relies on the 8x36 screw to hold the housing on.

First, chuck a drill bit upside down in your drill press and set the table where you can the vise as a guide for your hacksaw. Turn on the press and cut the bit off. With my method you will actually cut 2 pieces off the bit. One for the stud and one to mark the housing with.

On one of the pieces, chuck it up in the press and use a file to turn it down to a point.

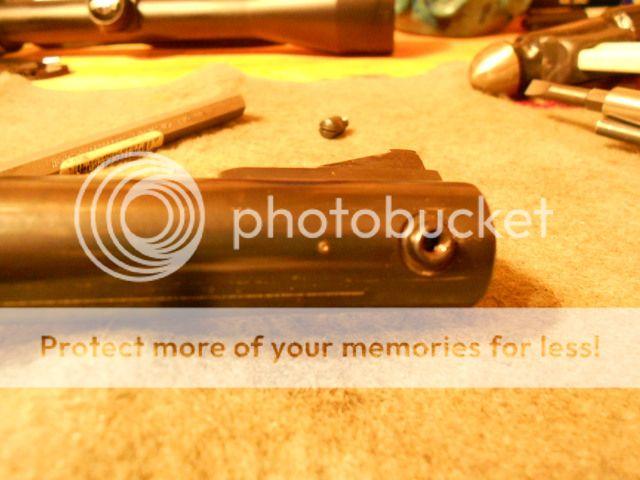

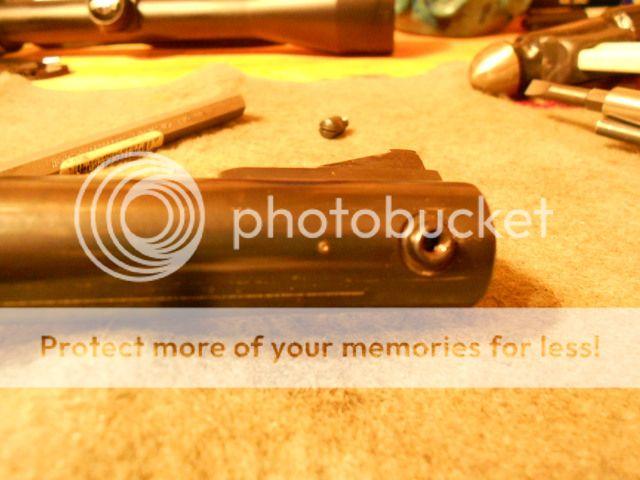

Mark the location of the stud on the barrel close to the screw. This will let the housing lay as close to flat as possible for marking the housing later on. Clamp the revolver in the press and install the housing screw to use as a guide to make sure you are drilling perpendicular to the barrel.

Then it is time to mark the housing

This piece will be used to mark the housing. Once the hole is drilled in the barrel, you shorten it until is barely sticks above the surface of the hole. Then you install the housing, tighten the screw and tap the housing with a hammer to mark the center of the hole, and then drill the housing. This insures that the hole in the barrel lines up perfectly with the hold in the housing. Otherwise there would be slop between the pin and the housing and it wouldn't help take the force of recoil off the screw.

Once the housing is drilled, remove the pointed piece and install the stud you made from the bit. I would clamp it in a pair of straight jaw vice grips near the bottom to add some ridges and make it a press fit in the barrel in addition to soldering it in or using some epoxy. Once it is seated in the barrel, trim the top so it sits flush with the inside with the housing and doesn't impede the ejector.

Seems like a simple solution to the problem of shearing the screw on hard kicking revolvers.

First, chuck a drill bit upside down in your drill press and set the table where you can the vise as a guide for your hacksaw. Turn on the press and cut the bit off. With my method you will actually cut 2 pieces off the bit. One for the stud and one to mark the housing with.

On one of the pieces, chuck it up in the press and use a file to turn it down to a point.

Mark the location of the stud on the barrel close to the screw. This will let the housing lay as close to flat as possible for marking the housing later on. Clamp the revolver in the press and install the housing screw to use as a guide to make sure you are drilling perpendicular to the barrel.

Then it is time to mark the housing

This piece will be used to mark the housing. Once the hole is drilled in the barrel, you shorten it until is barely sticks above the surface of the hole. Then you install the housing, tighten the screw and tap the housing with a hammer to mark the center of the hole, and then drill the housing. This insures that the hole in the barrel lines up perfectly with the hold in the housing. Otherwise there would be slop between the pin and the housing and it wouldn't help take the force of recoil off the screw.

Once the housing is drilled, remove the pointed piece and install the stud you made from the bit. I would clamp it in a pair of straight jaw vice grips near the bottom to add some ridges and make it a press fit in the barrel in addition to soldering it in or using some epoxy. Once it is seated in the barrel, trim the top so it sits flush with the inside with the housing and doesn't impede the ejector.

Seems like a simple solution to the problem of shearing the screw on hard kicking revolvers.