callshot

Blackhawk

I have been feeling well enough to get out of the house and do some smelting lead. The weather has been exceptionalloy :wink: :wink: good and Dick lent me his plumbers pot and cast iron muffin tin. This first picture is of the pot and a wire spool table. It had been drug into my garage for the night and I took the picture the next morning.

This is a better picture of the pot.

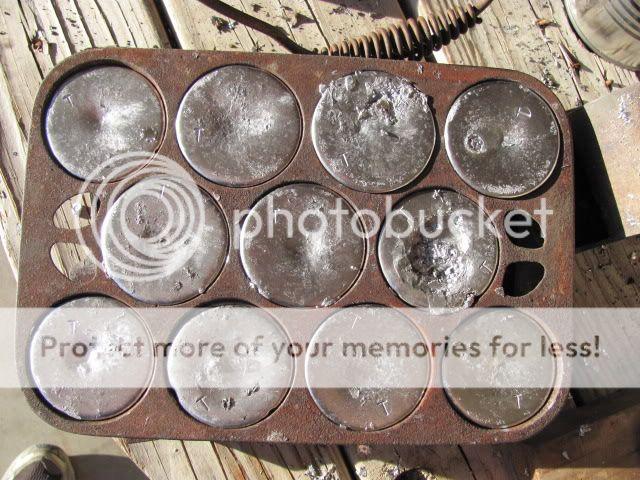

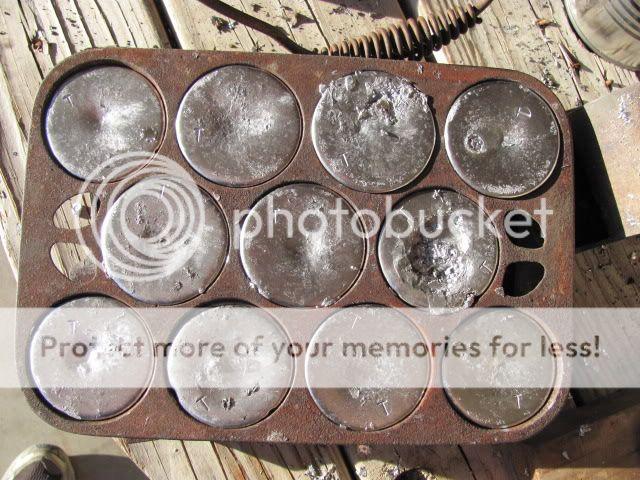

This is the cast iron muffin tin full of lead. They come out at 2 lbs. each.

My muffin tin only has 6 wells. They only weigh 1 and 1/2 lbs each. If I get the pot full, and fluxed it will fill both muffin tins.

This is some bees wax that I use to flux with. I used to be a beekeeper and had this on hand.

This is a picture of the clips, valve stems, and other dross and junk that I get out of the pot after fluxing.

This is a picture of the wheel weights that are NOT lead. They will not melt down and are just heavy junk.

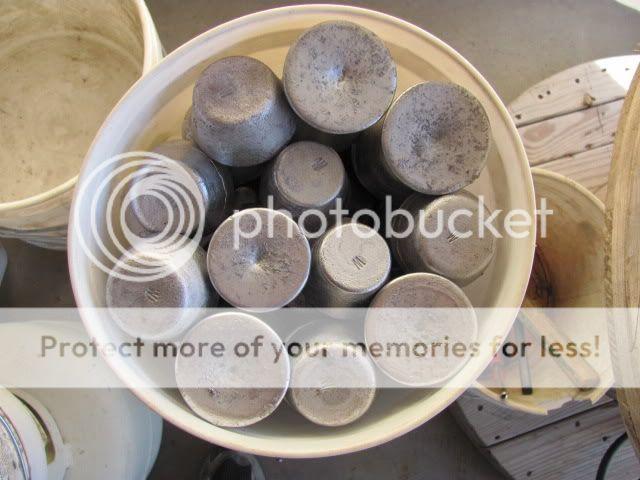

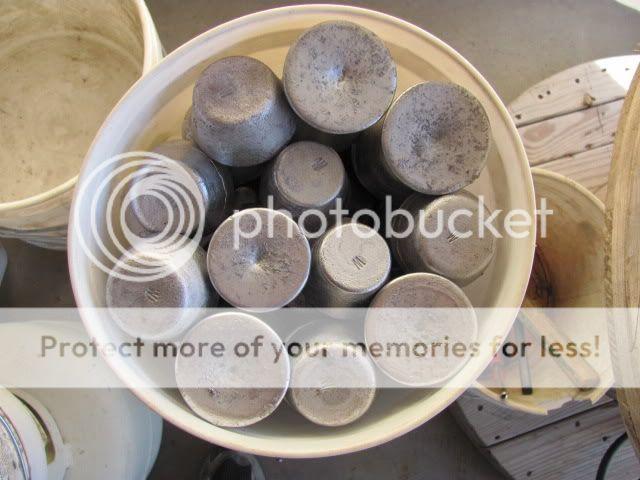

This is a bucket of ingots after they have cooled off. DANGER :!: Don't try to lift it by yourself.

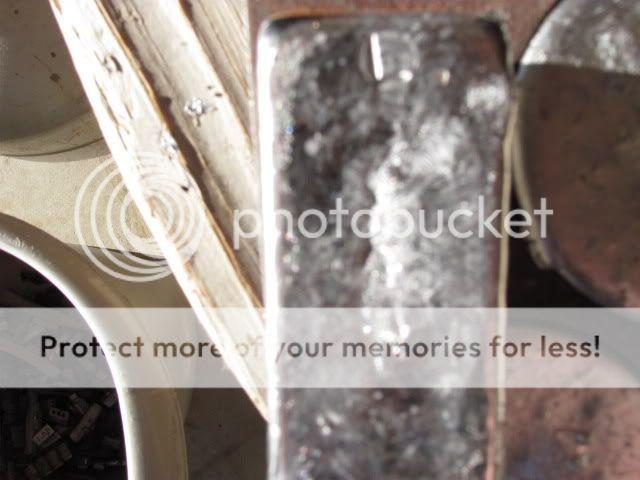

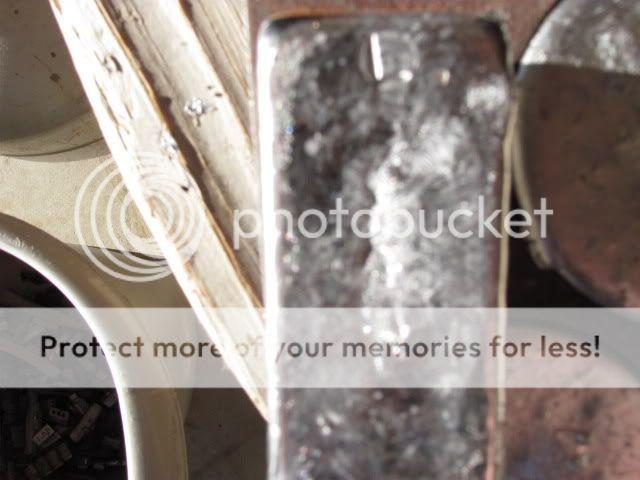

This is some of the ingots that didn't fit in the bucket, YET. :roll:

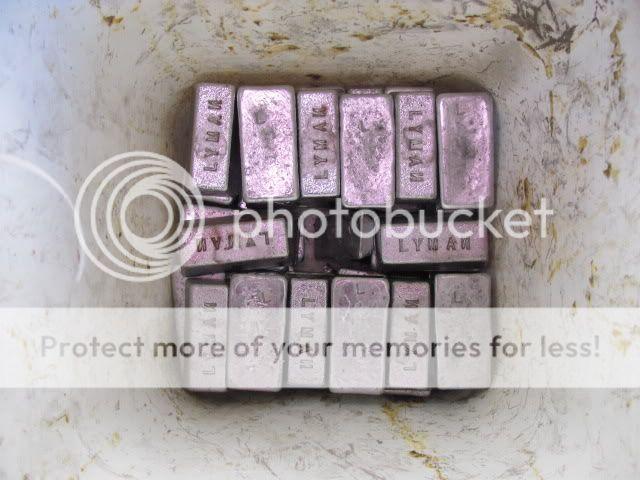

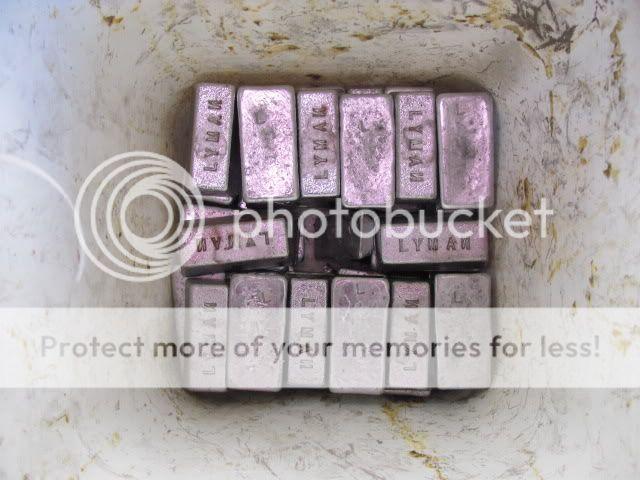

When casting different alloys, I need to mark them so I will know what they are. Note: "The most faded ink is better than my memory" I use some steel stamps to mark the ingots. "W" is for wheel weights.

"L" is for straight lead.

I used Dick's 1 lb. ingot moulds, and made them different shape to help me measure them into my casting furnace.

"T" is for linotype. I use the same muffin tins for it, because most of the alloy will be mixed at 50-50 "W & T".

I smelted down 517 lbs of ingots in the last 4 days and still had time to do a little other stuff around the house. That should keep me going (casting bullets) for some time now. My sore, aching back will never be the same until I rest up for the winter. Maybe house work isn't Soooo bad.

This is a better picture of the pot.

This is the cast iron muffin tin full of lead. They come out at 2 lbs. each.

My muffin tin only has 6 wells. They only weigh 1 and 1/2 lbs each. If I get the pot full, and fluxed it will fill both muffin tins.

This is some bees wax that I use to flux with. I used to be a beekeeper and had this on hand.

This is a picture of the clips, valve stems, and other dross and junk that I get out of the pot after fluxing.

This is a picture of the wheel weights that are NOT lead. They will not melt down and are just heavy junk.

This is a bucket of ingots after they have cooled off. DANGER :!: Don't try to lift it by yourself.

This is some of the ingots that didn't fit in the bucket, YET. :roll:

When casting different alloys, I need to mark them so I will know what they are. Note: "The most faded ink is better than my memory" I use some steel stamps to mark the ingots. "W" is for wheel weights.

"L" is for straight lead.

I used Dick's 1 lb. ingot moulds, and made them different shape to help me measure them into my casting furnace.

"T" is for linotype. I use the same muffin tins for it, because most of the alloy will be mixed at 50-50 "W & T".

I smelted down 517 lbs of ingots in the last 4 days and still had time to do a little other stuff around the house. That should keep me going (casting bullets) for some time now. My sore, aching back will never be the same until I rest up for the winter. Maybe house work isn't Soooo bad.