Jeff Hoover

Blackhawk

- Joined

- Feb 25, 2009

- Messages

- 919

There's a new rage sweeping thru the small world of those that choose to pour their own bullets from molten lead alloy called powder coating (PC). Giving these home brewed projectiles a new face in any color under the rainbow has been interesting to say the least. At first, I took it as a passing fad, and had no interest. Shooting my traditional cast beauties has been perfectly satisfactory up to this point. Why would I want to make bullets that looked like Skittles candy? Good friend Dick Thompson, aka 'sixshot' on the Forums, was the first to experiment with the new fad that I personally knew of. I was cold at first to the new technique, questioning what gains could be made compared to traditional sizing and lubing? Dick reported good accuracy, no leading what so ever, and the fact that a lot of bullets could be treated with PC with a pound of powder that cost about the same as a stick of premium bullet lube. After treating over 9,000 bullets, he still had over a ½ pound of powder left over. Pretty impressive! I started looking at Youtube videos and reading about PC on numerous forums. Curiosity was getting the better of me, and after much cogitation, a plan was formed to delve into the dark underworld of PC bullets. Many scoff at the new idea, and I did too, at first. I thought it was just about the colors people were enthralled with.

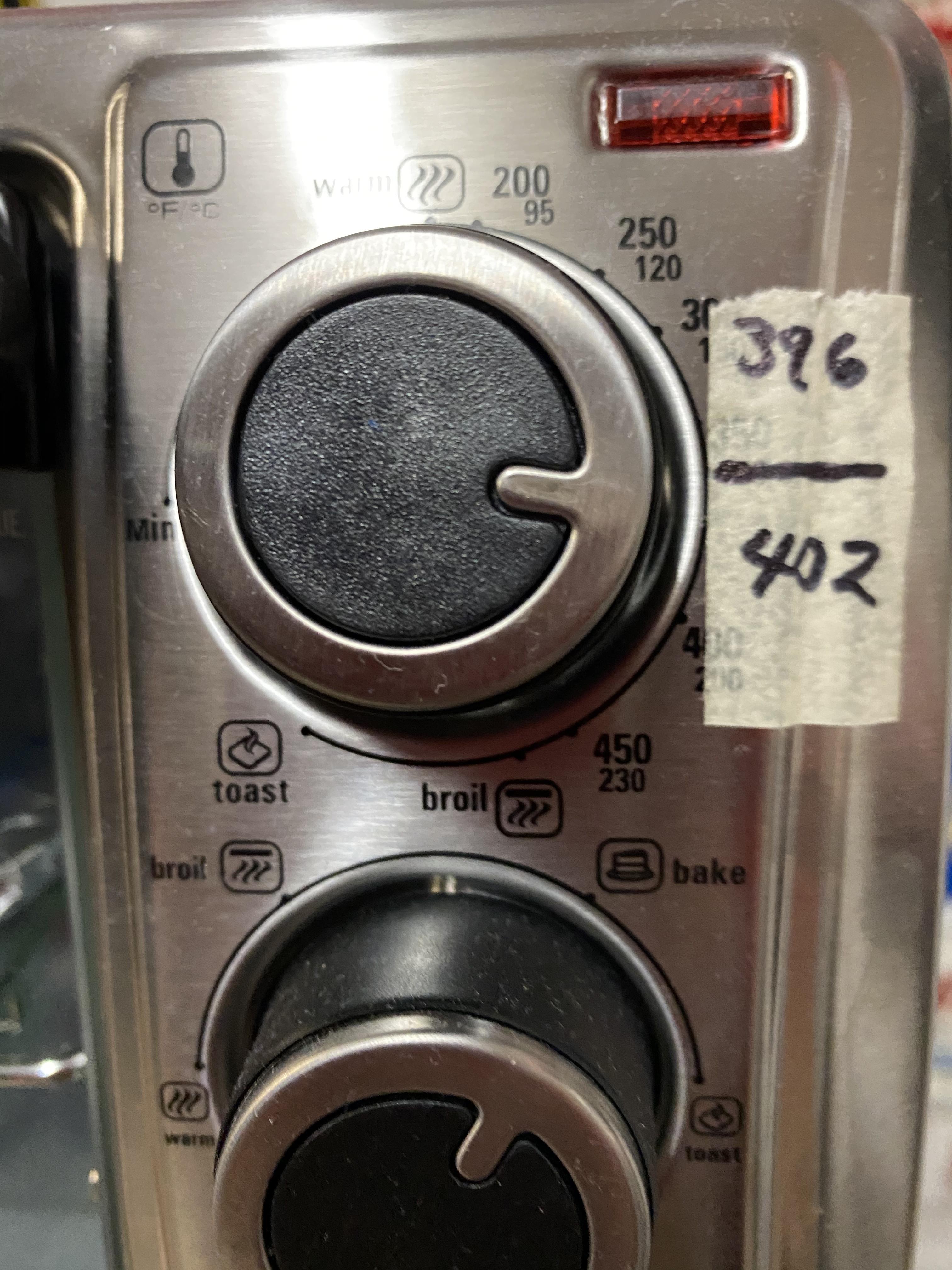

There are numerous ways to apply the PC. Sprayers, using paint thinners, Tupperware containers, cool whip dishes, and brass tumblers, to name a few. My first attempt was done with a Tupperware container. You simply place 40-50 cast bullets inside, add a little Harbor Freight PC, put the lid on and shake, rattle, and roll the bullets for a couple of minutes, until the bullets are totally covered. Once, covered, you place them onto a tray of nonstick aluminum foil and bake at 400 degrees. I did 16 minutes the first time and it seemed to work well, so I stick with it as my time. The once shiny bullets were transformed into red PC projectiles. Easy enough! But to capture my interest further, I wanted a way to process bullets by the hundreds, surpassing my rate with the arm fatiguing RCBS Lub-A-Matic II. After more cogitation, I decided to try the brass tumbler method. 4-500 bullets were dumped in the tumbler, powder applied, and after a 20 minute whirl, the bullets were uniformly coated as I ate a sandwich. Now that was simple! I was happy with the ease of coating my bullets that way. Next, I dumped, that's right, dumped my PC bullets onto a nonstick foil tray. They were on their sides, over laying each other. I wanted quick and easy, so tried it this way. Into the oven for a 16 minute 400 degree transformation.

Bullets dropped and powder sprinkled.

After their 20 minute PC whirlpool.

After a 20 minute 400 degree bake.

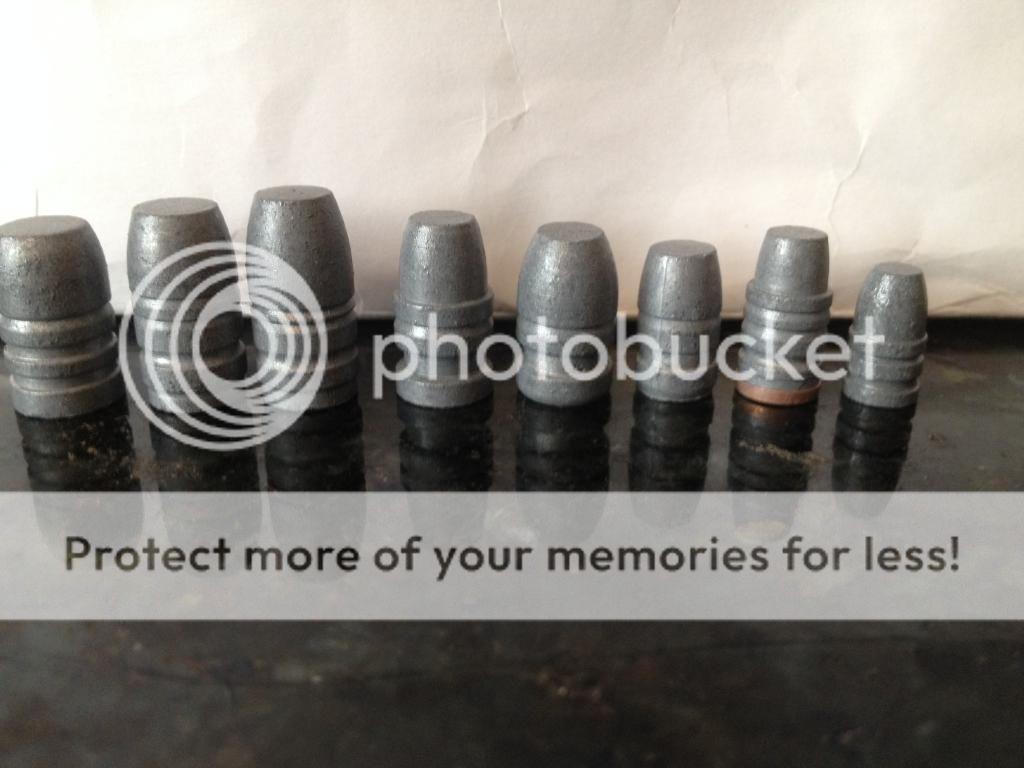

Some of the earth tone colors I stumbled into.

OK, Now I have my PC bullets. My original purchase of Harbor Freight powder coat was 2 pounds of red and some yellow. Red was fine, but some were turned off by lipstick looking bullets. I tried various combos of red and yellow to get more of an earth tone color. Finally, trying to appeal to diehard traditional cast bullet curmudgeons, I thought of mixing white and a touch of black to come up with a shade of grey that would look close to lead slugs.

Totally convinced that I could process hundreds of cast bullets for shooting faster than the traditional method of lubing and sizing, if these PC bullets would equal the traditionally sized and lubed slugs, I would have been happy, and still feel that I was coming out way ahead of the game just by the simple reason of ease and speed of PC these bullets. If the bullets chambered in the gun, I didn't bother sizing them. Although, sizing with a LEE push thru sizer is a lot easier and cleaner than the traditional method of the RCBS Lub-A-Matic II. So I was still ahead with the PC method, in my mind.

Just as the proof is in the pudding, the true test was gonna be performance at the range. To say that I was impressed would be an understatement! I shot clean guns, dirty guns, and guns that I was disappointed in with their accuracy with traditional cast. All the guns were shot clean by the PC bullets. That is, their barrels were free of lead, with just a touch of powder residue. The loads I shot were all on the stiff side too. What really impressed me was how well my Marlin lever guns took to the PC bullets. I think this is for several reasons. When baking, my usually hard water quenched bullets soften to a bhn of about 10. The PC is tough. It is said to be around 24 bhn. When throwing rejects into the pot, the lead will melt inside the PC jacket, and then dissolve, or melt into the alloy a minute or so later. These soft slugs will bump up if need be, while the tough PC shell engages the rifling. Whatever it is, it sure works!

This is about typical of the results I get using the PC bullets. .32 H & R RCBS 100 gr SWC, over 11.6 grs H110. 12 shots, 25 yards. Ammo loaded in same batch. The blue painters tape is 1.5" .

187 WFN, no gas check applied, .38 spc, 12.6 grs 2400, 50 yards. Best this rifle has ever shot with cast or jacketed slugs. It has done it numerous times too.

Here's the Lyman 160 gr RNFP cowboy bullet over 12.6 grs 2400 in .38 spc. This slug never shot well in the Marlin until PC. Again, 50 yards.

Numerous shots with Ruger Bisley at 25 yards with Skeeter load and PC Keith slug.

12 shots, 25 yards, Ruger Bisley Hunter .41 mag 250 gr WFN over 17 grs 2400.

I've had 7 range sessions shooting PC bullets, each time shooting between 3-400 a session. Each time I finish, I am simply amazed at the results. Most groups are reduced 30-50 %. The barrels are clean, needing only a wet patch to clean, tho I never really had a problem with leading shooting regular cast handloads of mine. I don't sell these bullets and have no skin in the game promoting the PC slugs. I believe PC is one of the most innovative things to hit the cast shooter arena. Since PC my bullets, I have processed 7-8 5 lb. coffee cans full of bullets. It is easy and fast. Think of it this way for the non conformist to PC bullets, it is nothing more than a new way to lube your bullets. No more, No less. I am anxious to get my other rifles into this PC game. I've coated a few bullets and need to load them so I can feed my rifles and see how they do.

Here are a few positives off the top of my head using PC bullets.

1) Speed of processing bullets

2) Better accuracy

3) Cheaper than premium bullet lube

4) Neater handling of bullets. Dies stay clean, as do hands.

5) Undersized molds can now be used as bullets are usually .002" larger after PC

6) Barrels are clean after shooting

7) No risk of lead oxidation for long term storage of bullets.

I hope I don't come off as a snake oil salesman. I was genuinely surprised and amazed at the results I got using PC bullets. We all get set in our ways, especially as we age. "What the hell do I need to do that for? Looks stupid to me!" Yet, every now and then, you can teach and old dog a new trick. Sometimes that old dog gets a nice big juicy bone for trying that trick, too!

There are numerous ways to apply the PC. Sprayers, using paint thinners, Tupperware containers, cool whip dishes, and brass tumblers, to name a few. My first attempt was done with a Tupperware container. You simply place 40-50 cast bullets inside, add a little Harbor Freight PC, put the lid on and shake, rattle, and roll the bullets for a couple of minutes, until the bullets are totally covered. Once, covered, you place them onto a tray of nonstick aluminum foil and bake at 400 degrees. I did 16 minutes the first time and it seemed to work well, so I stick with it as my time. The once shiny bullets were transformed into red PC projectiles. Easy enough! But to capture my interest further, I wanted a way to process bullets by the hundreds, surpassing my rate with the arm fatiguing RCBS Lub-A-Matic II. After more cogitation, I decided to try the brass tumbler method. 4-500 bullets were dumped in the tumbler, powder applied, and after a 20 minute whirl, the bullets were uniformly coated as I ate a sandwich. Now that was simple! I was happy with the ease of coating my bullets that way. Next, I dumped, that's right, dumped my PC bullets onto a nonstick foil tray. They were on their sides, over laying each other. I wanted quick and easy, so tried it this way. Into the oven for a 16 minute 400 degree transformation.

Bullets dropped and powder sprinkled.

After their 20 minute PC whirlpool.

After a 20 minute 400 degree bake.

Some of the earth tone colors I stumbled into.

OK, Now I have my PC bullets. My original purchase of Harbor Freight powder coat was 2 pounds of red and some yellow. Red was fine, but some were turned off by lipstick looking bullets. I tried various combos of red and yellow to get more of an earth tone color. Finally, trying to appeal to diehard traditional cast bullet curmudgeons, I thought of mixing white and a touch of black to come up with a shade of grey that would look close to lead slugs.

Totally convinced that I could process hundreds of cast bullets for shooting faster than the traditional method of lubing and sizing, if these PC bullets would equal the traditionally sized and lubed slugs, I would have been happy, and still feel that I was coming out way ahead of the game just by the simple reason of ease and speed of PC these bullets. If the bullets chambered in the gun, I didn't bother sizing them. Although, sizing with a LEE push thru sizer is a lot easier and cleaner than the traditional method of the RCBS Lub-A-Matic II. So I was still ahead with the PC method, in my mind.

Just as the proof is in the pudding, the true test was gonna be performance at the range. To say that I was impressed would be an understatement! I shot clean guns, dirty guns, and guns that I was disappointed in with their accuracy with traditional cast. All the guns were shot clean by the PC bullets. That is, their barrels were free of lead, with just a touch of powder residue. The loads I shot were all on the stiff side too. What really impressed me was how well my Marlin lever guns took to the PC bullets. I think this is for several reasons. When baking, my usually hard water quenched bullets soften to a bhn of about 10. The PC is tough. It is said to be around 24 bhn. When throwing rejects into the pot, the lead will melt inside the PC jacket, and then dissolve, or melt into the alloy a minute or so later. These soft slugs will bump up if need be, while the tough PC shell engages the rifling. Whatever it is, it sure works!

This is about typical of the results I get using the PC bullets. .32 H & R RCBS 100 gr SWC, over 11.6 grs H110. 12 shots, 25 yards. Ammo loaded in same batch. The blue painters tape is 1.5" .

187 WFN, no gas check applied, .38 spc, 12.6 grs 2400, 50 yards. Best this rifle has ever shot with cast or jacketed slugs. It has done it numerous times too.

Here's the Lyman 160 gr RNFP cowboy bullet over 12.6 grs 2400 in .38 spc. This slug never shot well in the Marlin until PC. Again, 50 yards.

Numerous shots with Ruger Bisley at 25 yards with Skeeter load and PC Keith slug.

12 shots, 25 yards, Ruger Bisley Hunter .41 mag 250 gr WFN over 17 grs 2400.

I've had 7 range sessions shooting PC bullets, each time shooting between 3-400 a session. Each time I finish, I am simply amazed at the results. Most groups are reduced 30-50 %. The barrels are clean, needing only a wet patch to clean, tho I never really had a problem with leading shooting regular cast handloads of mine. I don't sell these bullets and have no skin in the game promoting the PC slugs. I believe PC is one of the most innovative things to hit the cast shooter arena. Since PC my bullets, I have processed 7-8 5 lb. coffee cans full of bullets. It is easy and fast. Think of it this way for the non conformist to PC bullets, it is nothing more than a new way to lube your bullets. No more, No less. I am anxious to get my other rifles into this PC game. I've coated a few bullets and need to load them so I can feed my rifles and see how they do.

Here are a few positives off the top of my head using PC bullets.

1) Speed of processing bullets

2) Better accuracy

3) Cheaper than premium bullet lube

4) Neater handling of bullets. Dies stay clean, as do hands.

5) Undersized molds can now be used as bullets are usually .002" larger after PC

6) Barrels are clean after shooting

7) No risk of lead oxidation for long term storage of bullets.

I hope I don't come off as a snake oil salesman. I was genuinely surprised and amazed at the results I got using PC bullets. We all get set in our ways, especially as we age. "What the hell do I need to do that for? Looks stupid to me!" Yet, every now and then, you can teach and old dog a new trick. Sometimes that old dog gets a nice big juicy bone for trying that trick, too!