deac45

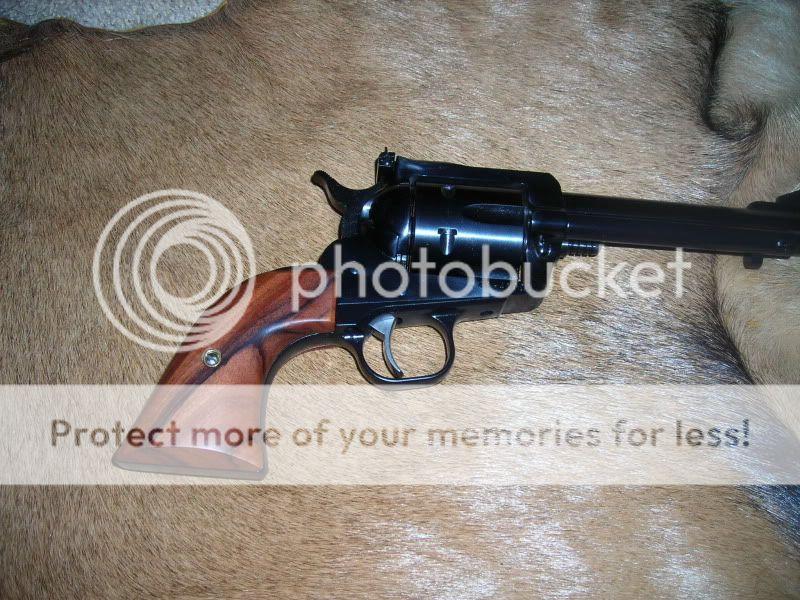

Single-Sixer

Nice work! I happen to prefer little or no bevel on the bottom.

deac45

deac45

knuckles":s7h2qc5q said:Heck' they look as good as factory... nice!

29 Wheelgunner":yicm0m3y said:Excellent job, are you sure that they are your first?

JSimpson65":1euz9eev said:29 Wheelgunner":1euz9eev said:Excellent job, are you sure that they are your first?

Thanks, I'll take that as a compliment.