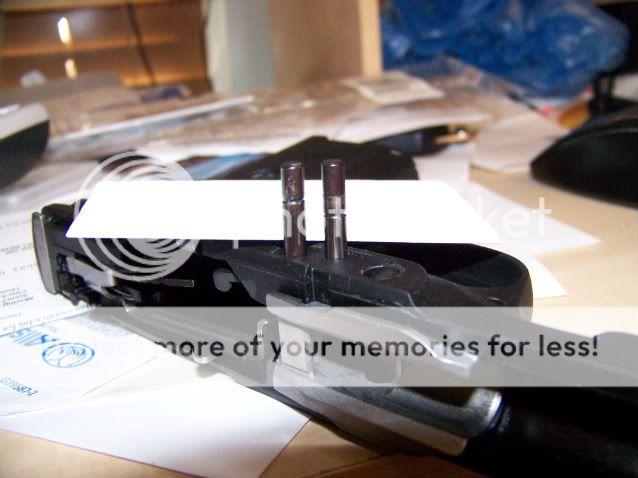

I did a teardown on my SR9 last night to see how big of a task it was, and by following the detailed instructions posted by jhearne I was able to get it apart with relative ease. The problem I'm having now is getting the rearward takedown pin back into the camblock and through the gun. As far as I can tell the holes line up, but the small pin/spring that seats in the side of the camblock seems to be impeding my ability to drive the pin through. Any thoughts?

Also, I can't seem to get the pin holding mag release out either. Is it too supposed to be punched out from the right side of the gun to the left like all the other pins? My mag release is sticking to the point where it won't release on it's own if I push it from the left side. I've tried oiling it to no avail so a teardown and cleaning seems to be the only feasible option. Thanks in advance for the help.

Also, I can't seem to get the pin holding mag release out either. Is it too supposed to be punched out from the right side of the gun to the left like all the other pins? My mag release is sticking to the point where it won't release on it's own if I push it from the left side. I've tried oiling it to no avail so a teardown and cleaning seems to be the only feasible option. Thanks in advance for the help.