jhearne

Buckeye

- Joined

- Jul 14, 2007

- Messages

- 1,365

Edit 10/16/13: Removed video links, took them down some time back along with my website. The info here is much more detailed and laid out than the videos would let me be. Sorry for forgetting to remove them all this time.

Ok guys/gals, this first post contains 5 sections, SR9 Field Strip, SR9 Magazine Disassembly, Magazine Disconnect Removal, SR9 Detail Strip to Internal Compenent Assemblies, and finally SR9 Internal Detail Strip with polish points. Since this is a VERY lengthy write-up, I have labeled above the "How-To's" of this post, and color coded them, below starting with the Magazine Disassembly, each section will be a different color. Hope this helps many more than it confuses.

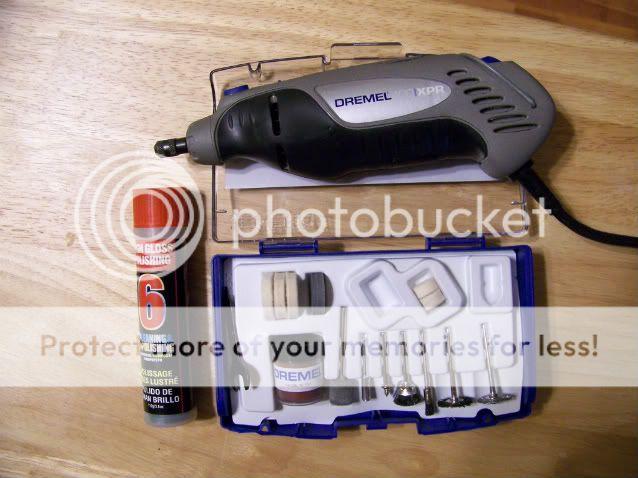

The Second Post of this thread will show the tools I used for those interested.

WARNING!!

Any and ALL precautions should be taken when removing ANY parts from ANY firearm. NEVER do any work without re-testing the functionality of the weapon. These pistols are tough and rugged, but not meant to be mishandled or neglected. Common Sense goes a VERY long way. If you are ever unsure about tearing into your firearm, please take it to a gunsmith and have them do the wanted work. I am and will not be held responsible for ANY misinterpretation or misuse of these How-To's.

Thank you,

Josh

Here we go!

NOTE: ALL Part Numbers I refer to will be from the NEW Part Listing provided by Ruger with my Retrofitted/Recalled SR9. For Retrofitted SR9 Pistols with Serial No. Prefix 330-XXXXX and new SR9 Pistols with Serial No. Prefix 331-XXXXX.

Click any Photo for a full size version of the 640 size preview I've made, the large photo SHOULD open in a new tab or window depending on your browser and settings.

Field Stripping the SR9

SR9 Video Field Strip How-To

Step 1, make SURE the gun is UNLOADED!....Triple check this step. I find it much easier when assembling and disassembling the SR9 to have an empty magazine to push up the ejector so you don't ever have to reach inside the gun.

Step 2, With an empty mag in place pull the slide back to it's easily locked position, another reason I say to use an empty magazine.

Step 3, Push from the right side of the frame the #51 - Takedown Pin Assembly with your finger tip and pull the pin from the left side using the flat, if you can't get it out with your fingertips just use a flathead screwdriver or a dime, something to gently pry out the pin. It's design was kept simple to be easily pulled after breaking it free from the right side.

Step 4, Push the Ejector down, this keeps the gun from cocking and allows you to simply remove the slide without any extra steps. You can use a pencil eraser (what the Manual suggests), or your finger, it's your choice.

Step 5, Pull the slide back and let it come forward, UNDER YOUR FORCE, do not Sling Shot OR use the Slide Release. Doing so could send the slide flying off the frame and dropping onto the ground if your not careful. Just control it's release and let it come off under your control.

Step 6, With the Slide off you can now pull the #27 Guide Rod Assembly out and then remove the #15 Barrel - 9mm from the Slide.

This concludes the Field Strip procedure. Refer to your part listing and Exploded View for part information on this, there are pictures in your manual of this procedure.

Magazine Disassembly

Here's the How-To for taking apart your SR9 Magazines, Old AND New Design, it doesn't matter. The only possible discrepancy is if your in a Capacity Limited State, meaning you have the 10 Round Magazines. Though They should be VERY similar if not the same procedure to take apart.

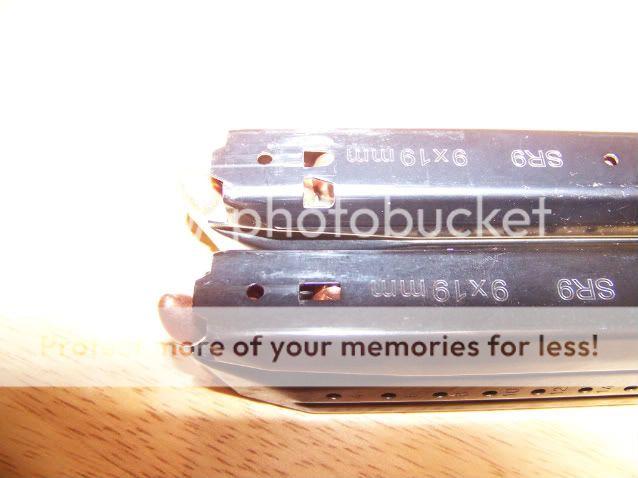

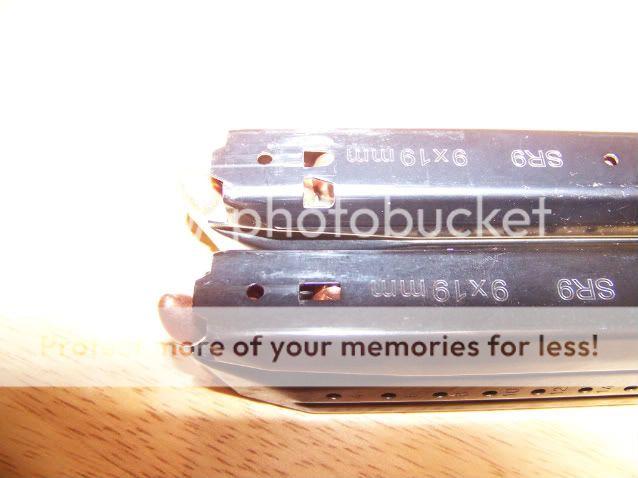

Here is the difference between the Old and New design magazines. The Old one is the U shaped catch, while the new one has a rectangular notch. I received the new one after the recall and the 2 old ones I have were with the gun at it's purchase.

I suggest taking apart one at a time, so you can use the other to reference how your progress is coming. The Follower should fit only one way in the ammo opening.

First, empty the magazine(s).

Locate the Assembly Pin in the bottom of the base plate. The way they assemble these mags is that on the bottom of the Spring there's a metal base plate before the plastic plate. The Metal plate has a nub that sticks out and fits in to the hole in the plastic plate.

To remove the Plastic Plate, take a small punch or pin and push the Metal nub while trying to push the plastic plate towards the front of the magazine. Once you get the pin out of the Plastic hole you can put down the tool. Keep one hand over the bottom so the Spring doesn't shoot out of the Mag Case, and ease the plastic cover plate off the bottom still pushing towards the front. The Spring should shoot the metal plate out with it, it's attached, but it comes off easily.

Pull the spring out with the follower, it is attached at the other end of the spring. Wipe out the inside of the case and clean what you would like to. Reverse the process to re-assemble the Magazine.

It's a very simple process, but a necessary one. Especially for those of us with old style magazines, when the noses of FMJ rounds catch the mag latch while loading mags, the shaving can pile up in the magazine. I've heard a few people here who cleaned them out and were amazed at what was in them.

Magazine Disconnect Removal How-To

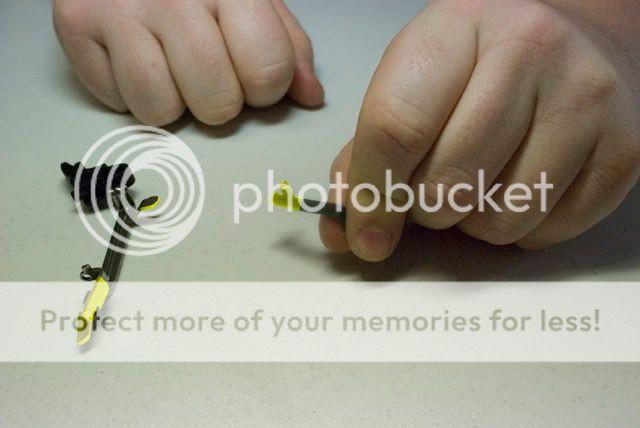

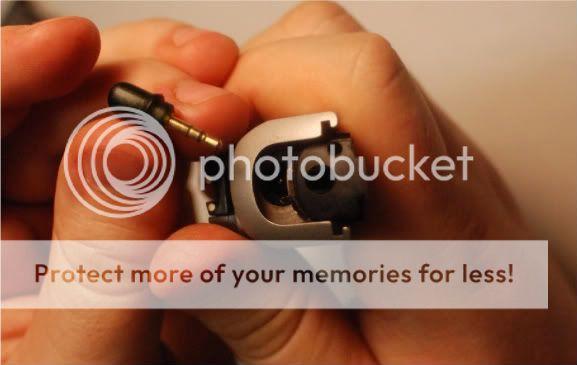

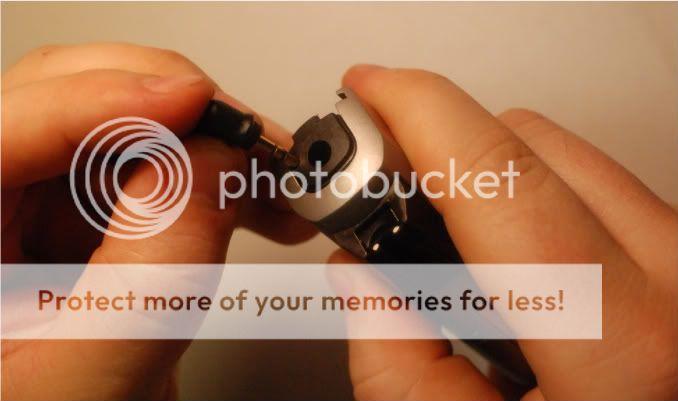

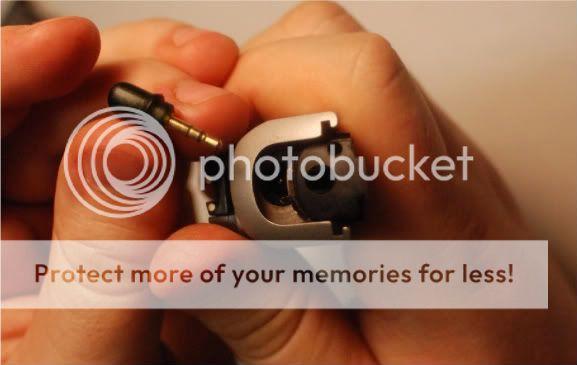

I will take you from a Field Stripped SR9 to a Stripped Slide with or without your #18 Magazine Disconnect in place. For this, aside from your Field Stripped SR9, you will need a utensil for compacting the #19 Striker Cover Spring by pressing the #20 Striker Cover Plunger. For this procedure I used a mini-plug off of an old headset, not the 1/8" plug size, but the much smaller one, it worked perfectly. Anything under 0.100" (1/10th of an Inch) should fit, Paper Clip, Bobby Pins, etc.....

Step 1 - Getting Acclimated to the Parts.

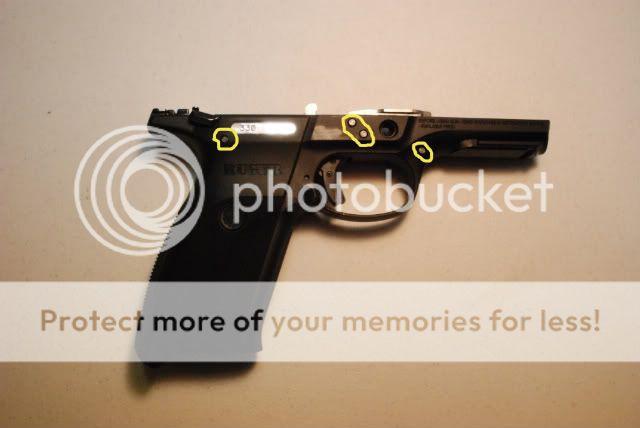

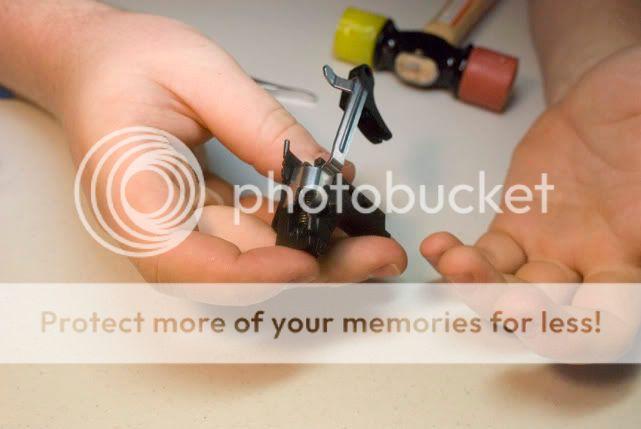

Locate the #17 Striker Blocker, #18 Magazine Disconnect and the Metal Tab on the #22 Striker itself. These are pointed to by the 3 Brass Rods, in order I listed from Left to Right in the photo.

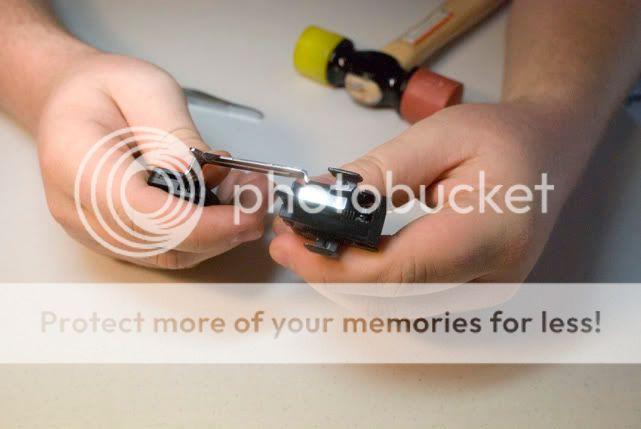

Step 2 - Setting the Striker for Removal.

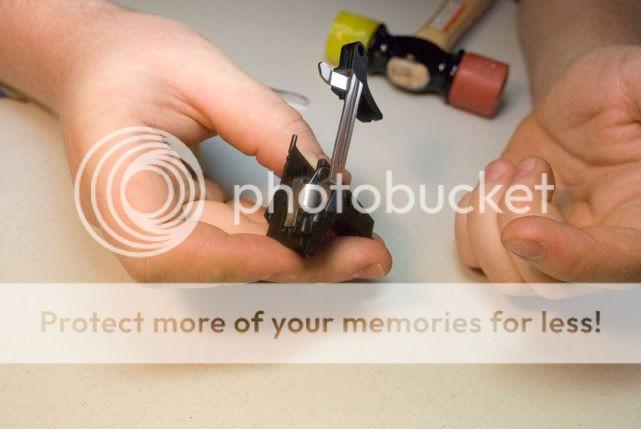

Press the Magazine Disconnect (Referred to as Mag DC from here on out) and while holding it in, push the metal tab on the Striker as far as it can go in, you shouldn't see the tip of the striker on the breechface as the Striker Blocker is doing it's job, blocking the striker. Release the Mag DC and press in the Striker Blocker, again while holding the Striker Blocker, push the Striker as far as it can go, you should now see the tip of the Striker in the Breechface.

Step 3 - Striker Cover Removal.

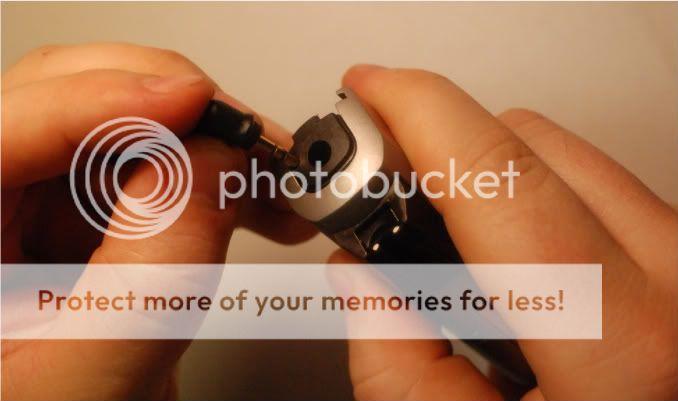

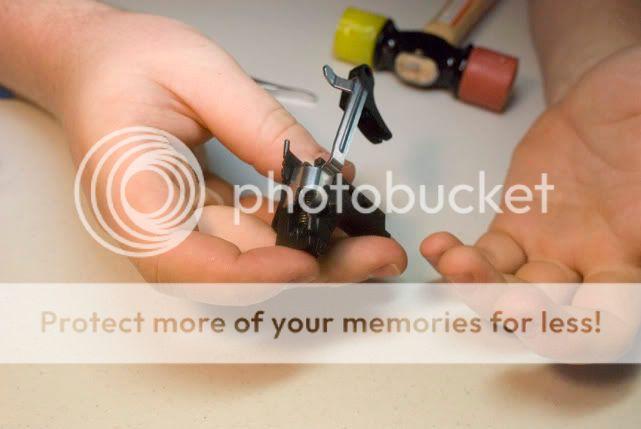

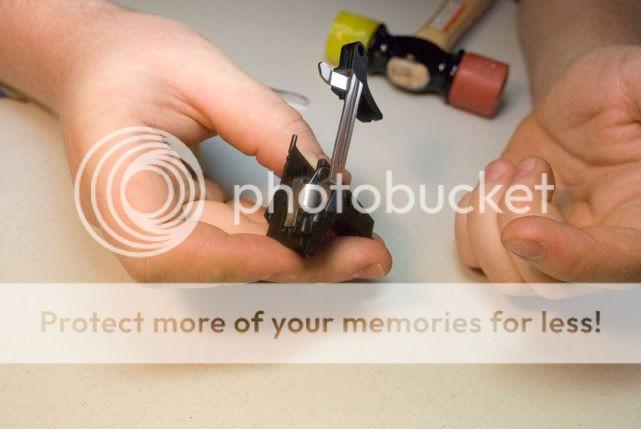

Once the Striker is clear of the #21 Striker Cover, take your small diameter tool and press the #20 Striker Cover Plunger as far in as you can make it go. You while doing so you should try to slide the Cover off towards the bottom of the Slide. Once you get it moving you can stop pressing the Plunger and continue to slide the Cover off. The Plunger and it's Spring can fly out, but I haven't had them jump out of the Slide yet. The Spring is stuck inside I figure.

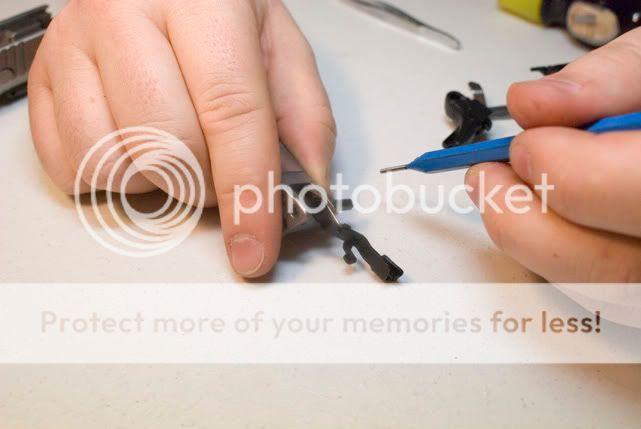

Step 4 - Striker and Mag DC Removal.

Remove the Striker from the slide, you may feel some resistance from the Mag DC applying friction against your removal of the Striker. It should come right out. Be careful when you get the Striker past the Mag DC as the Mag DC can jump out, nothing crazy but it can startle you, it did me my first time at this.

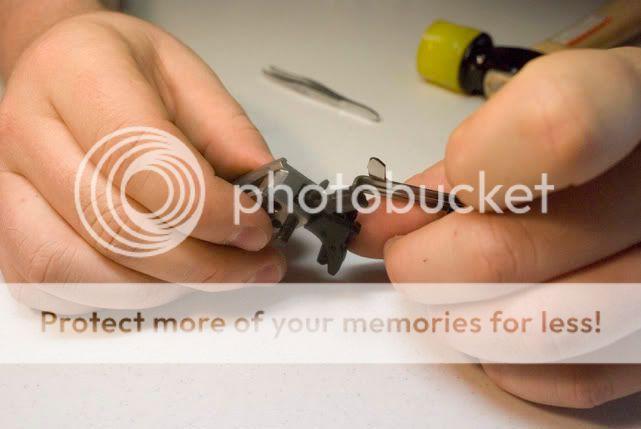

Step 5 - Slide Assembly.

Reinsert the Striker, be sure to press the Striker Blocker like before to set the Striker as far forward as possible. Then press in the Cover Plunger and re-install the Cover. Insert your Barrel and Guide Rod Assembly and your done after you re-assemble your pistol Slide to the Frame.

Congrats, you have just removed your Magazine Disconnect from your SR9.

NOTE: the Mag DC was designed by Ruger to be removable by you the owner/user. It has been speculated that removal could hurt you in Court if you ever had to use the SR9 in a Self/Home Defense case. It hasn't been used to our knowledge yet and may never be used. I have mine removed, IMHO removal of the Mag DC does nothing to any normal operational features of the gun, making it no more or less safe a weapon than it was from the factory. If I plan to use the gun, I'm going to use it, and store it to my own accordance with regards to my personal safety. I doubt any Lawyer will see things my way, but Gun Safety is Common Sense stuff, if you can't handle that, you shouldn't be looking to modify ANY part of your weapon. I accept ZERO responsibility for the misuse or neglect of your SR9 in EVERY situation it is used. You, the end user, are solely responsible for the safety of yourself and others around you.

If your looking for a lighter trigger, I DO NOT suggest you take a pair of cutters to your striker spring. I know it's stout but it was designed that way with an intent. Cutting springs weakens them but also can shorten their life. Do this the wrong way and you can break your Striker Spring Cup or Striker Shaft (both plastic pieces).

If you're adventurous and want a lighter/smoother trigger, I do suggest you try polishing, it's more work but safer if done patiently and with care, your trigger will feel much better than just lopping spring coils. I compare these two methods to food, Cutting springs is like a TV dinner, its quick and easy and only leaves you somewhat satisfied. Polishing parts is like cooking a nice thick steak, it takes longer and more effort is required to get it right but you should really enjoy the final product.

Any time you change something on your gun I suggest you hit the range and put a good bit of rounds through it to ensure everything is in working order. Always test your work for full functionality. This goes for both How-To's of this post (Mag DC and Detail Strip)

Again I am not responsible for anyone's shadetree gun smithing gone wrong. I am not a Smith, I am not an engineer, I do not claim to be either. I simply grasp concepts pretty well and have a mind for tinkering with things. I like find ways to apply what I learn through things like these How-To's.

With that said, lets try and tackle a detail strip to the frame and main components.

Detail Strip

Step 1 - Getting Acclimated again.

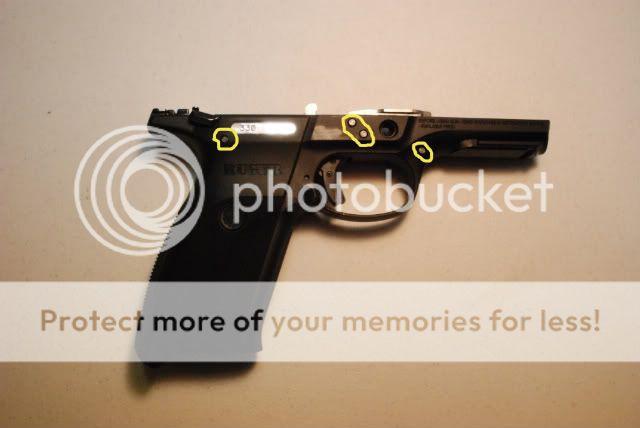

Take your Field Stripped SR9 and locate the 4 Pins that will be driven out from the RIGHT SIDE of the Frame. They are from Left to Right in the photo below, #56 Fire Control Housing Pin; #53 Camblock Pin, Upper; #52 Camblock Pin, Lower; #50 Camblock Pin, Front

Step 2 - Pin Removal.

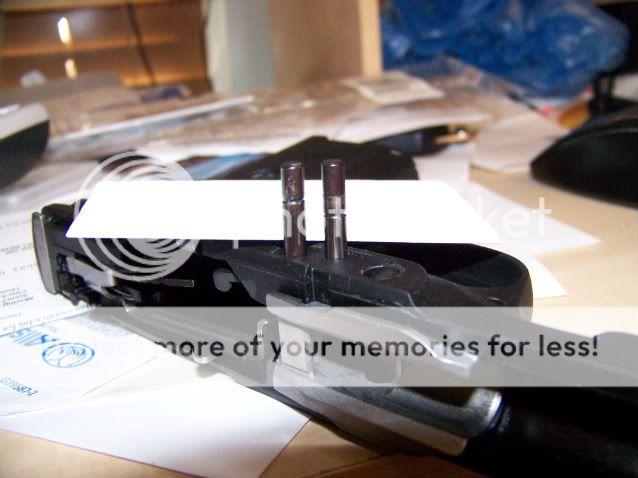

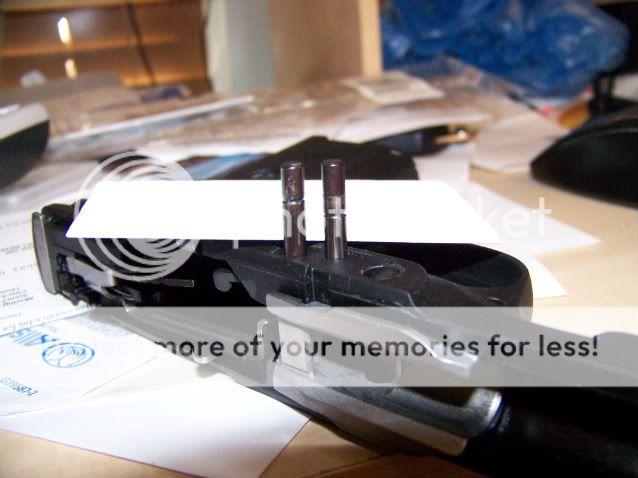

Drive out the 3 Camblock Pins, the Front pin drives out fairly easily. The Upper and Lower pins require a little more force, use a small hammer or mallet to help, use Brass Punches to drive these out, they are retained by the #31 Camblock Pin Retainer, the #30 Camblock Pin, Front Retainer is an O-Ring essentially that holds the Front Camblock Pin in place. Remove these from Right to left.

Please Note: Pins #52 and #53 are different. The retaining grooves are in different locations. Pin #53's groove is closest to the end. Both grooves are to fit the left side of the frame. The pin on the left is #53 and the right is #52. Pin #50 isn't shown in the pic but the groove is slightly off-centered, and should fit the left side of the frame as well, it fits part #30, Camblock, Front Retainer; a simple O-Ring. Thanks to Hawkeye for pointing this out to me.

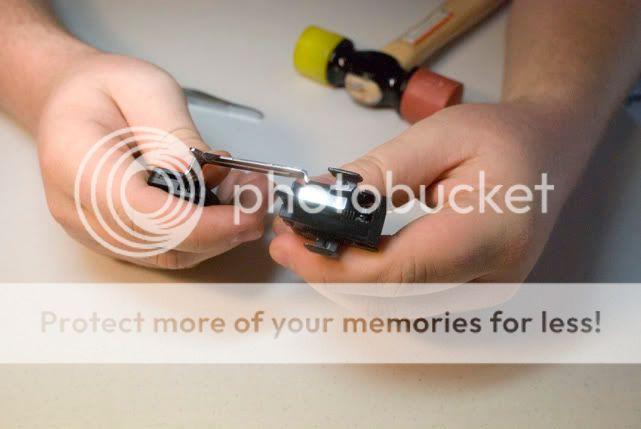

For the Fire Control Housing Pin, use the same punch and press, from the right side, while finding the sweet spot on the #42 Ejector. There is 2 noticeable positions, up and down, but in the right spot the pin can come out. There is some machine work on that pin, mainly a couple flat ground spots. On the Pin's head, the largest outside diameter part, there is a flat, this is important later, I'll remind you when.

Step 3 - Separation.

Using a small flathead screw driver or smaller pocketknife blade, gently pry the slide rails of the Camblock from the frame, Gently! Hold the frame with the Left side facing down, so the #31 Camblock Pin Retainer can fall out onto your surface, and not get lost. While doing this try and pry out the Fire Control Housing Assembly, DO NOT PULL THE ASSEMBLY OUT BY THE SAFETY LEVERS!! There is a chance mentioned in the other detail strip post that you could get the detents off and have a fun time re-aligning them. I forget exactly but it is still easy to pull the Assembly out without using those handy safety levers. You can gently pull on the Ejector, but if you can see the lip behind the safety levers you can get it started there, and in the back of the housing there's the pivot point for the safety levers, there's a lip just above them, and you can pry there as well. Once it gets past it's keeper spots it comes out fairly easily.

All of the guts are linked together after removal still. Further disassembly is required for those who wish to really detail clean or polish parts.

This is as far as I took my SR9 apart today. If you have the tools required you can go further than what I did and get the Fire Control Housing Assembly broken down and separate the trigger from the Trigger Bar.

Re-assembly....gently put the assemblies back in their proper locations. Be mindful to not forget the little wire Camblock Retainer, it is a spring by nature, but not a traditional wound one. You'll have to set it in place and finagle the spring in place while inserting the Camblock into the Frame, don't rush it and you'll be fine. Set the Fire Control Housing back in it's place and remember that the Ejector needs to be sort of halfway in between it's Up/Down positive set positions. Take the machined pin and make sure that while inserting it you wiggle the Ejector a bit to get it in the right position, as soon as the pin inserts most the way you can stop wiggling. Remember earlier when I mentioned I'd remind you about those flats on the pin's head? Now's that time, the Pin's Head Flat needs to be vertical, and with the flat towards the back end of the frame. (sorry I forgot to get a picture of this part). Look at your Exploded View to see what I mean, the flat is vertical (like a backwards uppercase "D"). Aligned like this the pin should freely push all the way in with minimal tools and force required. If you can't get the pin in without pressing it in, your doing it wrong. I ran into this problem last night and as soon as I looked at the Exploded View I adjusted it and tadaa!

Once the FC Housing is in place you may find that the 3 Camblock pin holes do not align properly. I found that if you push the Trigger bar forward and 'cock' the Trigger (you can simply pull the trigger forward as well) and then try to push the Camblock more into the frame it allows you to align all the holes. Drive the two Upper and Lower Camblock Pins in, the Groove in the 3 pins here go on the Left side of the Frame. Drive them Flush as you can get them, they need to be seated into the Takedown Pin pocket so the Takedown Pin can properly seat in the frame to clear the slide while cycling. Insert the Front Camblock Pin and adjust it flush as you can and your done with the Frame. Re-assemble the SR9 and dry fire the gun a few times to ensure proper cycling and to really make sure everything is fine, go hit the range.

SR9 DETAIL STRIP

Note: Your SR9 must be disassembled to the Frame and Main Internal Assemblies. If you haven't done this, please scroll up to the above section on doing so. After you have please come back to here and continue. This portion will get about 90% of your internal components apart, I haven't removed the Trigger from the Trigger Bar, the Trigger Bar Spring from the Fire Control Housing, the Inner Trigger (the Trigger Safety) from the Main Trigger, or removing the components for the Magazine Release. I will add these at a later time after I obtain smaller tools and a vise with the ability to hold the plastic pieces. I will also add a How-To on the FULL disassembly of the Slide and it's components at a later date. I don't want to damage any of the metal roll-pins by unecessarily forcing something out.

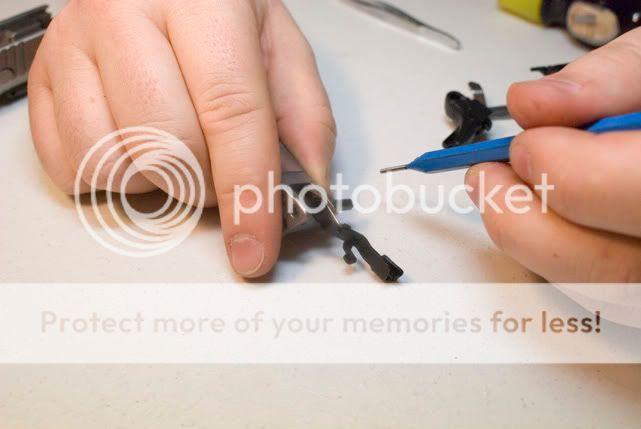

Step 1: Pin Location

There are 2 pins that will need to be driven out. On the left is #29, the Trigger Pivot Pin and on the right is #47, the Ejector Pivot Pin.

Step 2: Camblock/Slide Stop Removal

Drive out pin #29 from the right and #28, the Camblock; #33, the Slide Stop Lever Assembly should separate from the Trigger and the rest of what's still connected to the Trigger.

Step 3: Ejector Pin Removal and Safety Lever Flip

Drive out pin #47 from the right, it fits a little tight, but be gentle, it's all plastic on that housing and nothing needs to be broken or bent. The Ejector should still be in place, leave it for now.

Next, push the #46, Thumb Safety Assembly down, like your pushing past the fire detent if it were still a fully assembled gun. Careful as #48 Safety Detent Plunger and #49 Safety Detent Spring can come out a bit once the spring is released. NOTE: #48 and #49 are labeled as being 2 parts each, but labeled as the Safety Detent Plunger and Safety Detent Spring. There is another Plunger/Spring assembly that is underneath the Ejector, below the Ejector Pivot pin's hole we just drove out. This second Plunger/Spring assembly can fall out, my first strip didn't have it out, the second with these photos did.

Once the Detent/Spring is out you can simply pull the Safety Lever Assembly out of the Fire Control Housing (FCH), it snaps in and out of the back of the FCH. I left it in there for a few steps, however, it's specific removal is not a critical one, as long as it's been flipped and it's Detent Plunger/Spring has been removed your OK.

Step 4: Trigger Bar Separation

To 'loosen' the Trigger Bar, work it loose from its position, it's only held by #41 Trigger Bar Spring, and is sitting between the Safety Lever and #44, Trigger Bar Reset. Since the Safety Lever is out of the way the Trigger Bar is only resting there by the force of the spring, gently lift it away from the FCH and gently remove it from the spring. DO NOT FORCE IT, just manipulate its position until you get it off.

Step 5: Main Disassembly of the Fire Control Housing

The #42, Ejector can now be removed, just pull it forward and it should come out with little force required. #43 Trigger Bar Lift Spring should come out easily as well. #44 Trigger Bar Reset should come out easy but you may need to use a pair of tweezers to pull it out, do not pry, just lift it straight out from the FCH. Remember that the second Detent/Plunger may come out with the removal of the Ejector.

I did not remove the #41 Trigger Bar Spring, the pin needed to push it out is very small, and my smallest punch was a 1/16". It's removal isn't terribly necessary, unless your replacing it.

Step 6: Completely Apart

Congrats, if you've made it this far without substantial blood loss or kept a good deal of change in your pocket from your swear jar you've done well. I'm not responsible for those of you who did loose much blood. If you lost a couple bucks into your swear jar, don't sweat it, curse some more and go buy a cold one on me .

.

Step 7: Beginning FCH Reassembly

Replace the Ejector Detent Plunger/Spring assembly, you may need the tweezers for this.

While pressing in the Plunger, install the Ejector, once the edge of the Ejector is over the Plunger, you should be able to remove your pin/punch and slip the Ejector over the Plunger. After you get the Ejector in, replace it's pin, from left to right. The pin's overall width is less than the FCH width so it won't sit flush. I left mine sitting flush on the left side only. Refer to Step 1 of this section for the pin's location.

Snap in the Safety Lever Assembly but leave it flipped towards the back of the FCH.

Step 8: Trigger Bar Installation

Pull the Ejector forward, or push it down, however you prefer to call it, it has to be forward or the Trigger Bar cannot be installed properly. Orientate the FCH and Trigger Bar as they would sit as if fully assembled, rotate the Trigger Bar as if it were connected. Also flip the FCH so the spring falls out leaving it hooked end exposed to easily install the Trigger Bar. To install the Trigger Bar, you'll have to either flip the TB around so you see how it should connect to it spring or do some trial and error until you get it right. DO NOT FORCE ANYTHING on this part of reassembly. It's an easy part to get right or wrong, have patience and you'll get it right, this is a hard step to explain.

Step 9: Trigger Bar Reset and Lift Spring Install

Install the Trigger Bar Reset, there's a notch on both sides of the hole it fits into, it should slide right in, DO NOT FORCE IT. Once the TB Reset is in place, you'll need to position the Trigger Bar like it would sit if it were fully assembled. Now you'll flip the Safety Lever to it's Fire Detent, rotate it from the bottom of the FCH, you'll have to press in the Safety Detent Plunger/Spring and slide the Lever over the Plunger. It should snap into place once you get it there. The Safety Lever also retains the Trigger Bar Reset and captures the Trigger Bar between the Safety Lever and Trigger Bar Reset.

For the Lift Spring you'll put the end that has a sharp bend right at the end in the FCH letting the double looped spring part over the molded part it fits in. You'll have to manipulate the Lift Spring to fit under the Trigger Bar, it may take a little force, I used my fingers and not pliers or anything that could bend the spring out of shape, I suggest you do the same, it's not that hard. Once the spring is under the Trigger Bar you'll need to push the double loop part into its cutout final location.

Step 10: Check for Function

Before attaching the Camblock and Slide Stop, check the FCH assembly for proper function. You should be able to push the Trigger Bar forward and set it in place, and then release it. If it seems fine it probably is, if something breaks or comes loose or won't budge something's wrong probably. Take a picture of it if you can and post it here on this thread and we'll help you out, if not continue onto the next step.

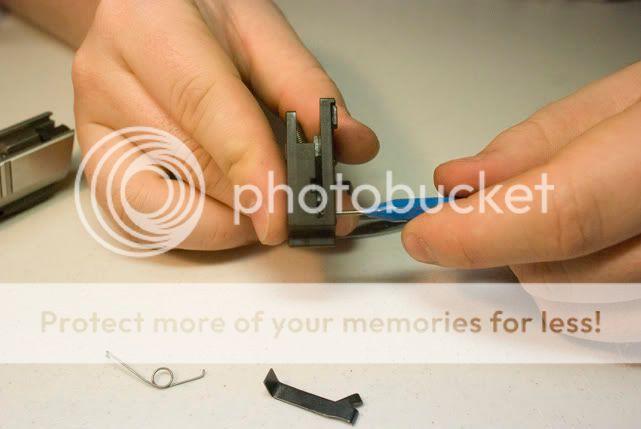

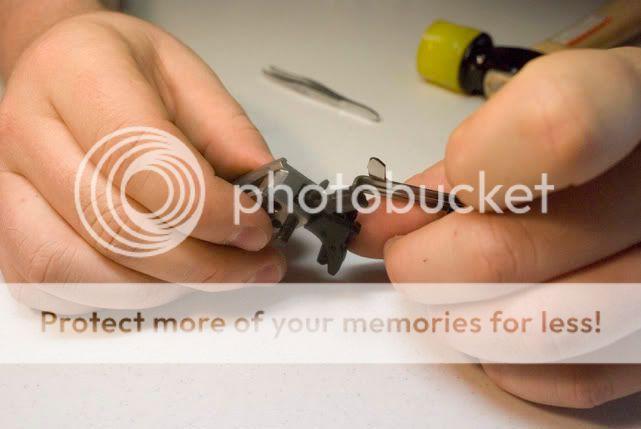

Step 11: Camblock/Slide Stop Lever Installation

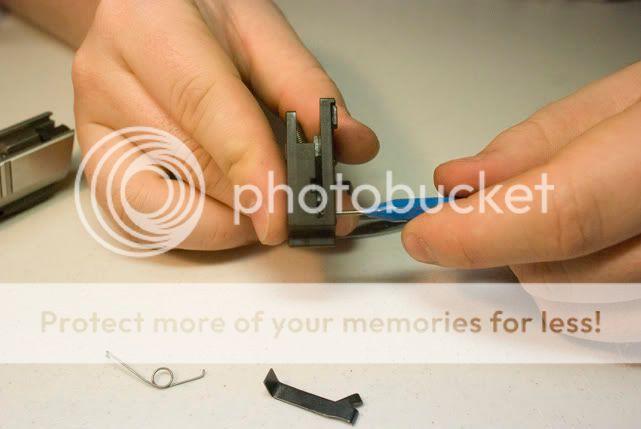

This part can be tricky as a few details need to be addressed.

First take the Trigger Pivot Pin and start it on the left side of the Camblock.

Now making sure that the loose spring end is inside the metal of the Camblock, push the pin in further capturing the Slide Stop Lever.

Push the Pin back out a bit so it sits flush with the inside edge of the Slide Stop Lever, so the trigger can be put into place. Set the Trigger in place and align the holes/pin and drive the pin flush.

Now you have reassembled the internal components of the Fire Control Mechanism(s)

Step 12: Finish Assembly

Go back to the Frame/Internal How-To and skip down to the Reassembly portion and finish putting your SR9 together. Hit the range and check for functionality before putting the SR9 back into your Self/Home Defense lineup. I hope this helped a bunch of you guys out, enjoy your SR9 guys/gals!

Please use this thread for Help or Suggestions ONLY. Anyone who wishes to discuss the legality of removing the Mag DC, I respectfully ask that you create a new thread and discuss it there. I want this to remain a How-To/Help thread only.

Special thanks to my father for taking the Pictures, those curious we used a Nikon D80 with 2 different lenses, we swapped after the first couple steps of the Mag DC removal. I couldn't tell you what they were, I'm not a photography buff. He's my Photographer for any and all of my GOOD gun photos.

Anyone who wishes to use my photos for reference later on, feel free to do so, I really don't mind.

Thanks all,

Josh

Ok guys/gals, this first post contains 5 sections, SR9 Field Strip, SR9 Magazine Disassembly, Magazine Disconnect Removal, SR9 Detail Strip to Internal Compenent Assemblies, and finally SR9 Internal Detail Strip with polish points. Since this is a VERY lengthy write-up, I have labeled above the "How-To's" of this post, and color coded them, below starting with the Magazine Disassembly, each section will be a different color. Hope this helps many more than it confuses.

The Second Post of this thread will show the tools I used for those interested.

WARNING!!

Any and ALL precautions should be taken when removing ANY parts from ANY firearm. NEVER do any work without re-testing the functionality of the weapon. These pistols are tough and rugged, but not meant to be mishandled or neglected. Common Sense goes a VERY long way. If you are ever unsure about tearing into your firearm, please take it to a gunsmith and have them do the wanted work. I am and will not be held responsible for ANY misinterpretation or misuse of these How-To's.

Thank you,

Josh

Here we go!

NOTE: ALL Part Numbers I refer to will be from the NEW Part Listing provided by Ruger with my Retrofitted/Recalled SR9. For Retrofitted SR9 Pistols with Serial No. Prefix 330-XXXXX and new SR9 Pistols with Serial No. Prefix 331-XXXXX.

Click any Photo for a full size version of the 640 size preview I've made, the large photo SHOULD open in a new tab or window depending on your browser and settings.

Field Stripping the SR9

SR9 Video Field Strip How-To

Step 1, make SURE the gun is UNLOADED!....Triple check this step. I find it much easier when assembling and disassembling the SR9 to have an empty magazine to push up the ejector so you don't ever have to reach inside the gun.

Step 2, With an empty mag in place pull the slide back to it's easily locked position, another reason I say to use an empty magazine.

Step 3, Push from the right side of the frame the #51 - Takedown Pin Assembly with your finger tip and pull the pin from the left side using the flat, if you can't get it out with your fingertips just use a flathead screwdriver or a dime, something to gently pry out the pin. It's design was kept simple to be easily pulled after breaking it free from the right side.

Step 4, Push the Ejector down, this keeps the gun from cocking and allows you to simply remove the slide without any extra steps. You can use a pencil eraser (what the Manual suggests), or your finger, it's your choice.

Step 5, Pull the slide back and let it come forward, UNDER YOUR FORCE, do not Sling Shot OR use the Slide Release. Doing so could send the slide flying off the frame and dropping onto the ground if your not careful. Just control it's release and let it come off under your control.

Step 6, With the Slide off you can now pull the #27 Guide Rod Assembly out and then remove the #15 Barrel - 9mm from the Slide.

This concludes the Field Strip procedure. Refer to your part listing and Exploded View for part information on this, there are pictures in your manual of this procedure.

Magazine Disassembly

Here's the How-To for taking apart your SR9 Magazines, Old AND New Design, it doesn't matter. The only possible discrepancy is if your in a Capacity Limited State, meaning you have the 10 Round Magazines. Though They should be VERY similar if not the same procedure to take apart.

Here is the difference between the Old and New design magazines. The Old one is the U shaped catch, while the new one has a rectangular notch. I received the new one after the recall and the 2 old ones I have were with the gun at it's purchase.

I suggest taking apart one at a time, so you can use the other to reference how your progress is coming. The Follower should fit only one way in the ammo opening.

First, empty the magazine(s).

Locate the Assembly Pin in the bottom of the base plate. The way they assemble these mags is that on the bottom of the Spring there's a metal base plate before the plastic plate. The Metal plate has a nub that sticks out and fits in to the hole in the plastic plate.

To remove the Plastic Plate, take a small punch or pin and push the Metal nub while trying to push the plastic plate towards the front of the magazine. Once you get the pin out of the Plastic hole you can put down the tool. Keep one hand over the bottom so the Spring doesn't shoot out of the Mag Case, and ease the plastic cover plate off the bottom still pushing towards the front. The Spring should shoot the metal plate out with it, it's attached, but it comes off easily.

Pull the spring out with the follower, it is attached at the other end of the spring. Wipe out the inside of the case and clean what you would like to. Reverse the process to re-assemble the Magazine.

It's a very simple process, but a necessary one. Especially for those of us with old style magazines, when the noses of FMJ rounds catch the mag latch while loading mags, the shaving can pile up in the magazine. I've heard a few people here who cleaned them out and were amazed at what was in them.

Magazine Disconnect Removal How-To

I will take you from a Field Stripped SR9 to a Stripped Slide with or without your #18 Magazine Disconnect in place. For this, aside from your Field Stripped SR9, you will need a utensil for compacting the #19 Striker Cover Spring by pressing the #20 Striker Cover Plunger. For this procedure I used a mini-plug off of an old headset, not the 1/8" plug size, but the much smaller one, it worked perfectly. Anything under 0.100" (1/10th of an Inch) should fit, Paper Clip, Bobby Pins, etc.....

Step 1 - Getting Acclimated to the Parts.

Locate the #17 Striker Blocker, #18 Magazine Disconnect and the Metal Tab on the #22 Striker itself. These are pointed to by the 3 Brass Rods, in order I listed from Left to Right in the photo.

Step 2 - Setting the Striker for Removal.

Press the Magazine Disconnect (Referred to as Mag DC from here on out) and while holding it in, push the metal tab on the Striker as far as it can go in, you shouldn't see the tip of the striker on the breechface as the Striker Blocker is doing it's job, blocking the striker. Release the Mag DC and press in the Striker Blocker, again while holding the Striker Blocker, push the Striker as far as it can go, you should now see the tip of the Striker in the Breechface.

Step 3 - Striker Cover Removal.

Once the Striker is clear of the #21 Striker Cover, take your small diameter tool and press the #20 Striker Cover Plunger as far in as you can make it go. You while doing so you should try to slide the Cover off towards the bottom of the Slide. Once you get it moving you can stop pressing the Plunger and continue to slide the Cover off. The Plunger and it's Spring can fly out, but I haven't had them jump out of the Slide yet. The Spring is stuck inside I figure.

Step 4 - Striker and Mag DC Removal.

Remove the Striker from the slide, you may feel some resistance from the Mag DC applying friction against your removal of the Striker. It should come right out. Be careful when you get the Striker past the Mag DC as the Mag DC can jump out, nothing crazy but it can startle you, it did me my first time at this.

Step 5 - Slide Assembly.

Reinsert the Striker, be sure to press the Striker Blocker like before to set the Striker as far forward as possible. Then press in the Cover Plunger and re-install the Cover. Insert your Barrel and Guide Rod Assembly and your done after you re-assemble your pistol Slide to the Frame.

Congrats, you have just removed your Magazine Disconnect from your SR9.

NOTE: the Mag DC was designed by Ruger to be removable by you the owner/user. It has been speculated that removal could hurt you in Court if you ever had to use the SR9 in a Self/Home Defense case. It hasn't been used to our knowledge yet and may never be used. I have mine removed, IMHO removal of the Mag DC does nothing to any normal operational features of the gun, making it no more or less safe a weapon than it was from the factory. If I plan to use the gun, I'm going to use it, and store it to my own accordance with regards to my personal safety. I doubt any Lawyer will see things my way, but Gun Safety is Common Sense stuff, if you can't handle that, you shouldn't be looking to modify ANY part of your weapon. I accept ZERO responsibility for the misuse or neglect of your SR9 in EVERY situation it is used. You, the end user, are solely responsible for the safety of yourself and others around you.

If your looking for a lighter trigger, I DO NOT suggest you take a pair of cutters to your striker spring. I know it's stout but it was designed that way with an intent. Cutting springs weakens them but also can shorten their life. Do this the wrong way and you can break your Striker Spring Cup or Striker Shaft (both plastic pieces).

If you're adventurous and want a lighter/smoother trigger, I do suggest you try polishing, it's more work but safer if done patiently and with care, your trigger will feel much better than just lopping spring coils. I compare these two methods to food, Cutting springs is like a TV dinner, its quick and easy and only leaves you somewhat satisfied. Polishing parts is like cooking a nice thick steak, it takes longer and more effort is required to get it right but you should really enjoy the final product.

Any time you change something on your gun I suggest you hit the range and put a good bit of rounds through it to ensure everything is in working order. Always test your work for full functionality. This goes for both How-To's of this post (Mag DC and Detail Strip)

Again I am not responsible for anyone's shadetree gun smithing gone wrong. I am not a Smith, I am not an engineer, I do not claim to be either. I simply grasp concepts pretty well and have a mind for tinkering with things. I like find ways to apply what I learn through things like these How-To's.

With that said, lets try and tackle a detail strip to the frame and main components.

Detail Strip

Step 1 - Getting Acclimated again.

Take your Field Stripped SR9 and locate the 4 Pins that will be driven out from the RIGHT SIDE of the Frame. They are from Left to Right in the photo below, #56 Fire Control Housing Pin; #53 Camblock Pin, Upper; #52 Camblock Pin, Lower; #50 Camblock Pin, Front

Step 2 - Pin Removal.

Drive out the 3 Camblock Pins, the Front pin drives out fairly easily. The Upper and Lower pins require a little more force, use a small hammer or mallet to help, use Brass Punches to drive these out, they are retained by the #31 Camblock Pin Retainer, the #30 Camblock Pin, Front Retainer is an O-Ring essentially that holds the Front Camblock Pin in place. Remove these from Right to left.

Please Note: Pins #52 and #53 are different. The retaining grooves are in different locations. Pin #53's groove is closest to the end. Both grooves are to fit the left side of the frame. The pin on the left is #53 and the right is #52. Pin #50 isn't shown in the pic but the groove is slightly off-centered, and should fit the left side of the frame as well, it fits part #30, Camblock, Front Retainer; a simple O-Ring. Thanks to Hawkeye for pointing this out to me.

For the Fire Control Housing Pin, use the same punch and press, from the right side, while finding the sweet spot on the #42 Ejector. There is 2 noticeable positions, up and down, but in the right spot the pin can come out. There is some machine work on that pin, mainly a couple flat ground spots. On the Pin's head, the largest outside diameter part, there is a flat, this is important later, I'll remind you when.

Step 3 - Separation.

Using a small flathead screw driver or smaller pocketknife blade, gently pry the slide rails of the Camblock from the frame, Gently! Hold the frame with the Left side facing down, so the #31 Camblock Pin Retainer can fall out onto your surface, and not get lost. While doing this try and pry out the Fire Control Housing Assembly, DO NOT PULL THE ASSEMBLY OUT BY THE SAFETY LEVERS!! There is a chance mentioned in the other detail strip post that you could get the detents off and have a fun time re-aligning them. I forget exactly but it is still easy to pull the Assembly out without using those handy safety levers. You can gently pull on the Ejector, but if you can see the lip behind the safety levers you can get it started there, and in the back of the housing there's the pivot point for the safety levers, there's a lip just above them, and you can pry there as well. Once it gets past it's keeper spots it comes out fairly easily.

All of the guts are linked together after removal still. Further disassembly is required for those who wish to really detail clean or polish parts.

This is as far as I took my SR9 apart today. If you have the tools required you can go further than what I did and get the Fire Control Housing Assembly broken down and separate the trigger from the Trigger Bar.

Re-assembly....gently put the assemblies back in their proper locations. Be mindful to not forget the little wire Camblock Retainer, it is a spring by nature, but not a traditional wound one. You'll have to set it in place and finagle the spring in place while inserting the Camblock into the Frame, don't rush it and you'll be fine. Set the Fire Control Housing back in it's place and remember that the Ejector needs to be sort of halfway in between it's Up/Down positive set positions. Take the machined pin and make sure that while inserting it you wiggle the Ejector a bit to get it in the right position, as soon as the pin inserts most the way you can stop wiggling. Remember earlier when I mentioned I'd remind you about those flats on the pin's head? Now's that time, the Pin's Head Flat needs to be vertical, and with the flat towards the back end of the frame. (sorry I forgot to get a picture of this part). Look at your Exploded View to see what I mean, the flat is vertical (like a backwards uppercase "D"). Aligned like this the pin should freely push all the way in with minimal tools and force required. If you can't get the pin in without pressing it in, your doing it wrong. I ran into this problem last night and as soon as I looked at the Exploded View I adjusted it and tadaa!

Once the FC Housing is in place you may find that the 3 Camblock pin holes do not align properly. I found that if you push the Trigger bar forward and 'cock' the Trigger (you can simply pull the trigger forward as well) and then try to push the Camblock more into the frame it allows you to align all the holes. Drive the two Upper and Lower Camblock Pins in, the Groove in the 3 pins here go on the Left side of the Frame. Drive them Flush as you can get them, they need to be seated into the Takedown Pin pocket so the Takedown Pin can properly seat in the frame to clear the slide while cycling. Insert the Front Camblock Pin and adjust it flush as you can and your done with the Frame. Re-assemble the SR9 and dry fire the gun a few times to ensure proper cycling and to really make sure everything is fine, go hit the range.

SR9 DETAIL STRIP

Note: Your SR9 must be disassembled to the Frame and Main Internal Assemblies. If you haven't done this, please scroll up to the above section on doing so. After you have please come back to here and continue. This portion will get about 90% of your internal components apart, I haven't removed the Trigger from the Trigger Bar, the Trigger Bar Spring from the Fire Control Housing, the Inner Trigger (the Trigger Safety) from the Main Trigger, or removing the components for the Magazine Release. I will add these at a later time after I obtain smaller tools and a vise with the ability to hold the plastic pieces. I will also add a How-To on the FULL disassembly of the Slide and it's components at a later date. I don't want to damage any of the metal roll-pins by unecessarily forcing something out.

Step 1: Pin Location

There are 2 pins that will need to be driven out. On the left is #29, the Trigger Pivot Pin and on the right is #47, the Ejector Pivot Pin.

Step 2: Camblock/Slide Stop Removal

Drive out pin #29 from the right and #28, the Camblock; #33, the Slide Stop Lever Assembly should separate from the Trigger and the rest of what's still connected to the Trigger.

Step 3: Ejector Pin Removal and Safety Lever Flip

Drive out pin #47 from the right, it fits a little tight, but be gentle, it's all plastic on that housing and nothing needs to be broken or bent. The Ejector should still be in place, leave it for now.

Next, push the #46, Thumb Safety Assembly down, like your pushing past the fire detent if it were still a fully assembled gun. Careful as #48 Safety Detent Plunger and #49 Safety Detent Spring can come out a bit once the spring is released. NOTE: #48 and #49 are labeled as being 2 parts each, but labeled as the Safety Detent Plunger and Safety Detent Spring. There is another Plunger/Spring assembly that is underneath the Ejector, below the Ejector Pivot pin's hole we just drove out. This second Plunger/Spring assembly can fall out, my first strip didn't have it out, the second with these photos did.

Once the Detent/Spring is out you can simply pull the Safety Lever Assembly out of the Fire Control Housing (FCH), it snaps in and out of the back of the FCH. I left it in there for a few steps, however, it's specific removal is not a critical one, as long as it's been flipped and it's Detent Plunger/Spring has been removed your OK.

Step 4: Trigger Bar Separation

To 'loosen' the Trigger Bar, work it loose from its position, it's only held by #41 Trigger Bar Spring, and is sitting between the Safety Lever and #44, Trigger Bar Reset. Since the Safety Lever is out of the way the Trigger Bar is only resting there by the force of the spring, gently lift it away from the FCH and gently remove it from the spring. DO NOT FORCE IT, just manipulate its position until you get it off.

Step 5: Main Disassembly of the Fire Control Housing

The #42, Ejector can now be removed, just pull it forward and it should come out with little force required. #43 Trigger Bar Lift Spring should come out easily as well. #44 Trigger Bar Reset should come out easy but you may need to use a pair of tweezers to pull it out, do not pry, just lift it straight out from the FCH. Remember that the second Detent/Plunger may come out with the removal of the Ejector.

I did not remove the #41 Trigger Bar Spring, the pin needed to push it out is very small, and my smallest punch was a 1/16". It's removal isn't terribly necessary, unless your replacing it.

Step 6: Completely Apart

Congrats, if you've made it this far without substantial blood loss or kept a good deal of change in your pocket from your swear jar you've done well. I'm not responsible for those of you who did loose much blood. If you lost a couple bucks into your swear jar, don't sweat it, curse some more and go buy a cold one on me

Step 7: Beginning FCH Reassembly

Replace the Ejector Detent Plunger/Spring assembly, you may need the tweezers for this.

While pressing in the Plunger, install the Ejector, once the edge of the Ejector is over the Plunger, you should be able to remove your pin/punch and slip the Ejector over the Plunger. After you get the Ejector in, replace it's pin, from left to right. The pin's overall width is less than the FCH width so it won't sit flush. I left mine sitting flush on the left side only. Refer to Step 1 of this section for the pin's location.

Snap in the Safety Lever Assembly but leave it flipped towards the back of the FCH.

Step 8: Trigger Bar Installation

Pull the Ejector forward, or push it down, however you prefer to call it, it has to be forward or the Trigger Bar cannot be installed properly. Orientate the FCH and Trigger Bar as they would sit as if fully assembled, rotate the Trigger Bar as if it were connected. Also flip the FCH so the spring falls out leaving it hooked end exposed to easily install the Trigger Bar. To install the Trigger Bar, you'll have to either flip the TB around so you see how it should connect to it spring or do some trial and error until you get it right. DO NOT FORCE ANYTHING on this part of reassembly. It's an easy part to get right or wrong, have patience and you'll get it right, this is a hard step to explain.

Step 9: Trigger Bar Reset and Lift Spring Install

Install the Trigger Bar Reset, there's a notch on both sides of the hole it fits into, it should slide right in, DO NOT FORCE IT. Once the TB Reset is in place, you'll need to position the Trigger Bar like it would sit if it were fully assembled. Now you'll flip the Safety Lever to it's Fire Detent, rotate it from the bottom of the FCH, you'll have to press in the Safety Detent Plunger/Spring and slide the Lever over the Plunger. It should snap into place once you get it there. The Safety Lever also retains the Trigger Bar Reset and captures the Trigger Bar between the Safety Lever and Trigger Bar Reset.

For the Lift Spring you'll put the end that has a sharp bend right at the end in the FCH letting the double looped spring part over the molded part it fits in. You'll have to manipulate the Lift Spring to fit under the Trigger Bar, it may take a little force, I used my fingers and not pliers or anything that could bend the spring out of shape, I suggest you do the same, it's not that hard. Once the spring is under the Trigger Bar you'll need to push the double loop part into its cutout final location.

Step 10: Check for Function

Before attaching the Camblock and Slide Stop, check the FCH assembly for proper function. You should be able to push the Trigger Bar forward and set it in place, and then release it. If it seems fine it probably is, if something breaks or comes loose or won't budge something's wrong probably. Take a picture of it if you can and post it here on this thread and we'll help you out, if not continue onto the next step.

Step 11: Camblock/Slide Stop Lever Installation

This part can be tricky as a few details need to be addressed.

First take the Trigger Pivot Pin and start it on the left side of the Camblock.

Now making sure that the loose spring end is inside the metal of the Camblock, push the pin in further capturing the Slide Stop Lever.

Push the Pin back out a bit so it sits flush with the inside edge of the Slide Stop Lever, so the trigger can be put into place. Set the Trigger in place and align the holes/pin and drive the pin flush.

Now you have reassembled the internal components of the Fire Control Mechanism(s)

Step 12: Finish Assembly

Go back to the Frame/Internal How-To and skip down to the Reassembly portion and finish putting your SR9 together. Hit the range and check for functionality before putting the SR9 back into your Self/Home Defense lineup. I hope this helped a bunch of you guys out, enjoy your SR9 guys/gals!

Please use this thread for Help or Suggestions ONLY. Anyone who wishes to discuss the legality of removing the Mag DC, I respectfully ask that you create a new thread and discuss it there. I want this to remain a How-To/Help thread only.

Special thanks to my father for taking the Pictures, those curious we used a Nikon D80 with 2 different lenses, we swapped after the first couple steps of the Mag DC removal. I couldn't tell you what they were, I'm not a photography buff. He's my Photographer for any and all of my GOOD gun photos.

Anyone who wishes to use my photos for reference later on, feel free to do so, I really don't mind.

Thanks all,

Josh