Aggie01

Blackhawk

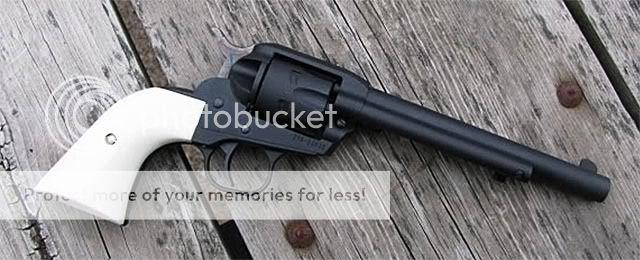

I think the perfect place for the XR3 is on a Single Six.

I have been accumulating spare NM steel XR3's for a while, and have finally gotten around to outfitting all of my Single Sixes with one.

Final fitting is not done on any but one, and it still hasn't been refinished. Not my best picture, but this morning all three of the Old Models were in various parts boxes. I had a local machinist knock out a batch of adapters for me and have spent the afternoon/night fitting and tweaking. Kinda fired up. I have owned the top left for at least two years and this is the first time it has had a gripframe or action on it.

Top Left: OM - 4.625", wearing Ruger takeoff ivory polymer ( it wasn't born with that barrel length)

Middle Left: OM - adjustable sight 5.5: Ruger takeoff ivory polymer

Bottom Left: OM - 5.5", wearing NC Ordance rosewood

Top Right: 32 Mag - 4.625" - born a bisley, and everything but the frame swapped out for Vaquerito parts. Wearing C Schultz stabilized buckeye burl (material provided by yours truly - and finished to be provided by yours truly sometime this summer).

Middle Right: 32 mag, 5.5" , wearing C Schultz American Holly

Bottom Right: 5.5" Convertable prewarning NM, wearing grips I picked up on this forum with no pedigree.

I have been accumulating spare NM steel XR3's for a while, and have finally gotten around to outfitting all of my Single Sixes with one.

Final fitting is not done on any but one, and it still hasn't been refinished. Not my best picture, but this morning all three of the Old Models were in various parts boxes. I had a local machinist knock out a batch of adapters for me and have spent the afternoon/night fitting and tweaking. Kinda fired up. I have owned the top left for at least two years and this is the first time it has had a gripframe or action on it.

Top Left: OM - 4.625", wearing Ruger takeoff ivory polymer ( it wasn't born with that barrel length)

Middle Left: OM - adjustable sight 5.5: Ruger takeoff ivory polymer

Bottom Left: OM - 5.5", wearing NC Ordance rosewood

Top Right: 32 Mag - 4.625" - born a bisley, and everything but the frame swapped out for Vaquerito parts. Wearing C Schultz stabilized buckeye burl (material provided by yours truly - and finished to be provided by yours truly sometime this summer).

Middle Right: 32 mag, 5.5" , wearing C Schultz American Holly

Bottom Right: 5.5" Convertable prewarning NM, wearing grips I picked up on this forum with no pedigree.