I'm a big Ruger fan and especially a No.1 fan and I'm really glad to have found this site!!! For my first post I thought I'd share a little project with you. I hope you like it as much as I did.

Whenever I frequent my area gun shops I like to look over their racks to see what they've bought or traded for. In February of 2008, low and behold I found a Ruger No.1, model 1-B in 30-06, on the used and abused rack. After fondling the rifle and examining the years of use and some abuse (mostly to the wood finish) I adopted this Ruger as my new pet for the mere sum of $325.00.

This rifle has a serial number prefix of #130, and from looking the number up on Ruger's website I found that the rifle was built late 1975 or sometime during early 1976. It is a pre-warning barrel but not a Liberty stamped barreled model. This serial number sequence does have the original and fully adjustable 3 screw trigger, that I adjusted to a very clean and crisp three pounds.

Originally I bought this rifle as a loaner or a donor rifle to re-barrel, thinking that this rifle as is might not shoot well due to old age and neglect. The finish on the wood looked scratched up and plain rough in a lot of places ..woof! The bluing was in fair shape except for what looked liked bloody fingerprints had removed. There sure was a lot of bore cleaning to do also!

While this Ruger hung out in my safe for a few months I contemplated what direction to take this rifle. The finish on this rifle had with age developed a sort of orange tint, and appeared to be "on the wood" instead of "in the wood." In the early 70's Ruger started using a spray polyurethane and that's why the finish had a glossy "on top" of the wood appearance.

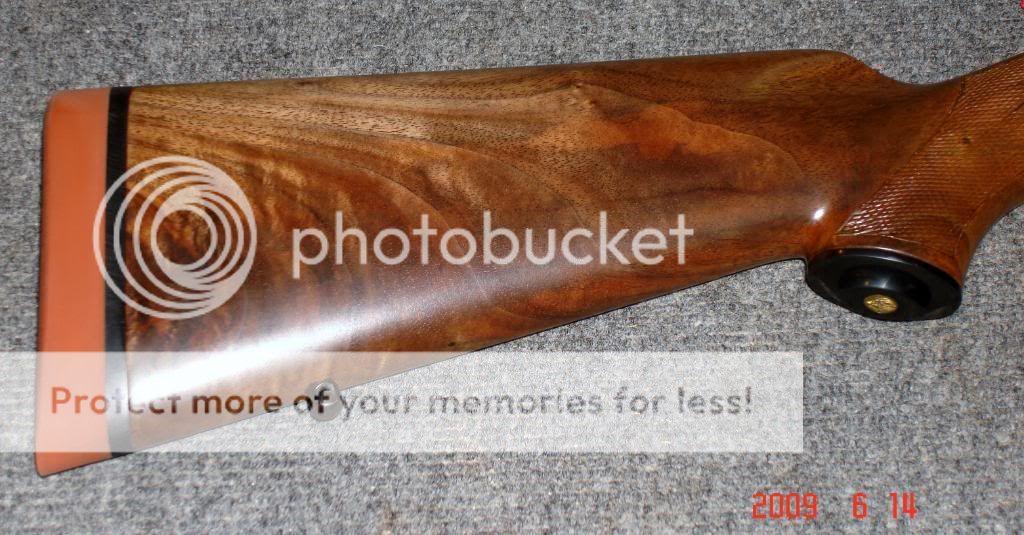

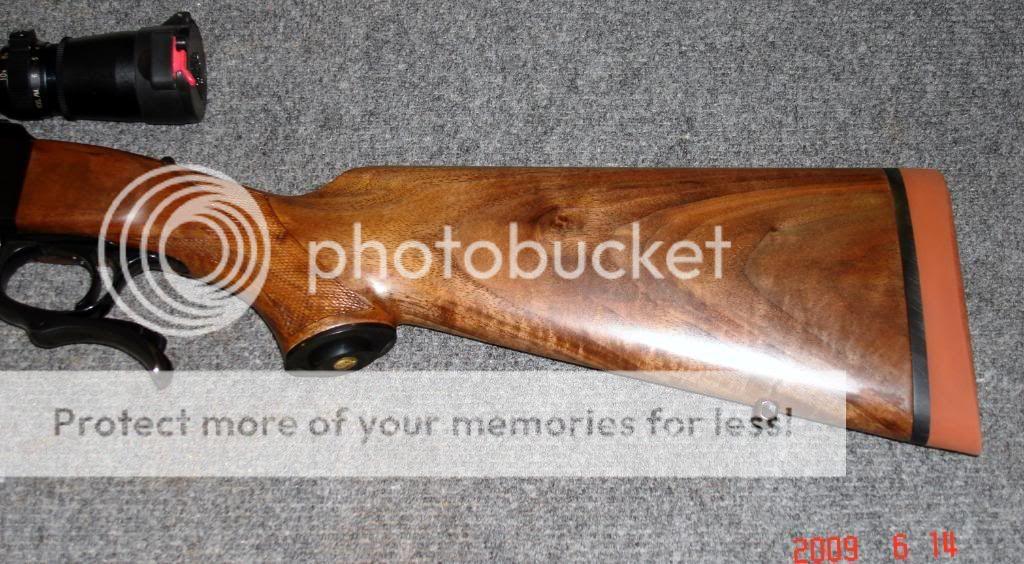

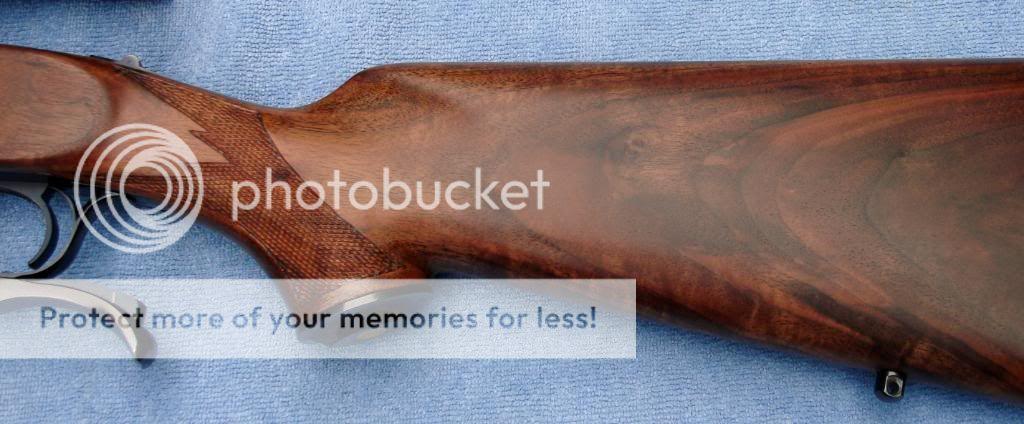

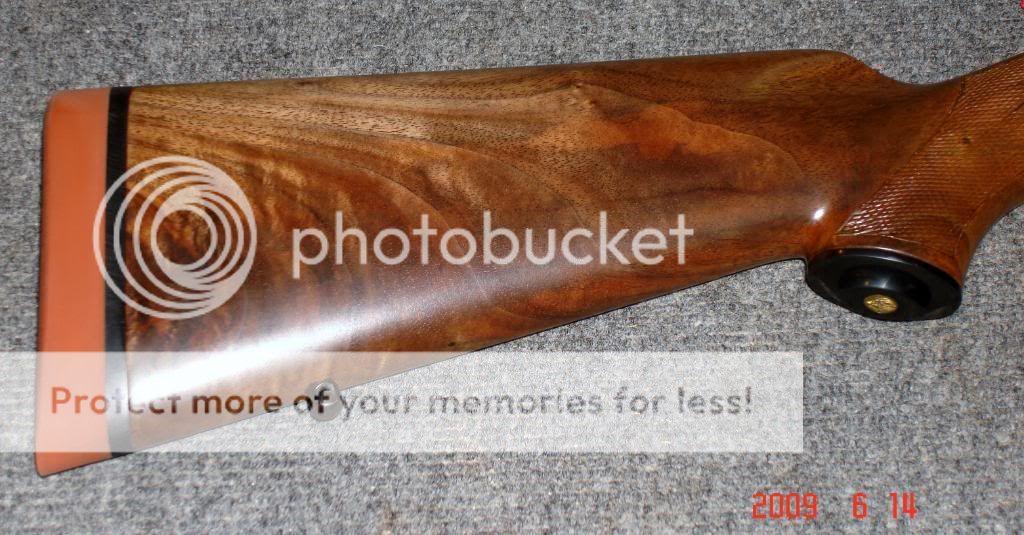

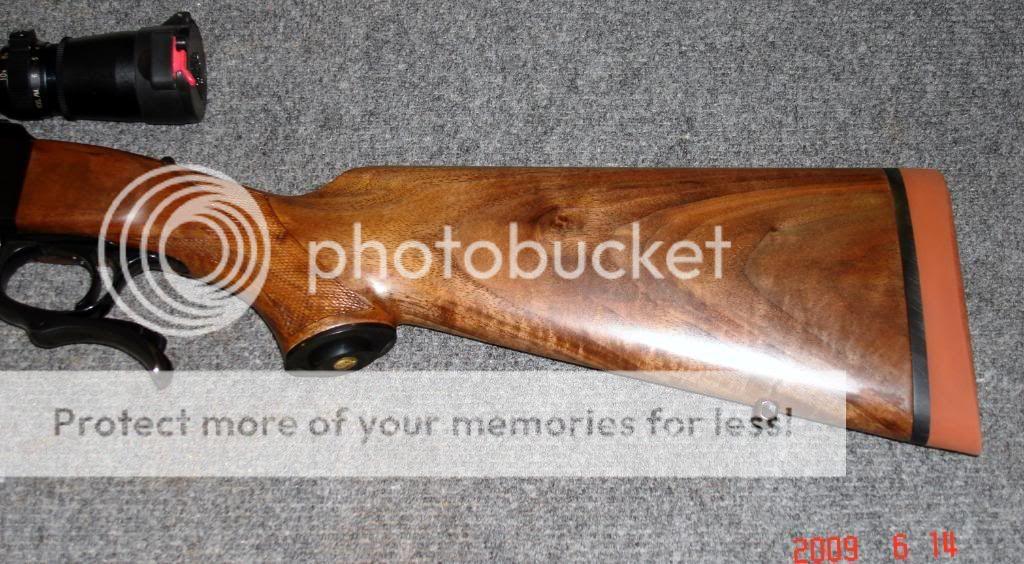

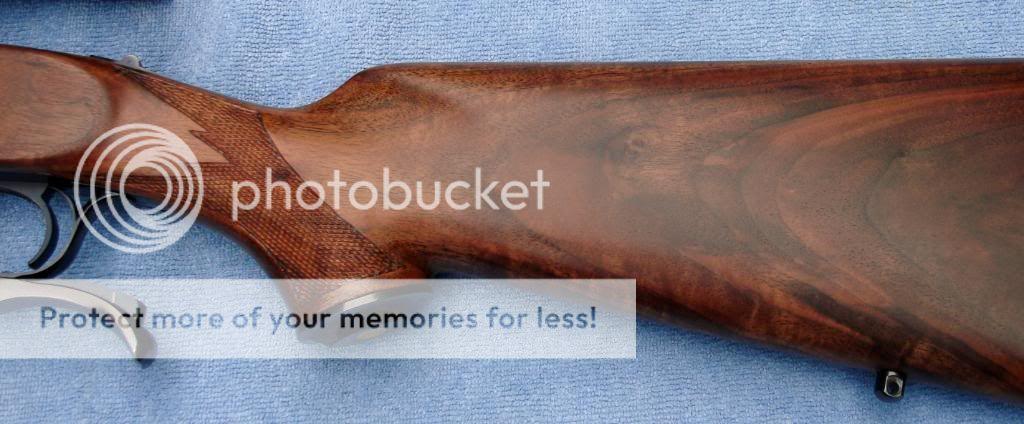

I stripped off the old finish, sanded the stock, and gave the bare-naked wood a hand rubbed lovingly applied oil finish. I love the look and warmth of an oil finished rifle stock best AND they are so easy to repair should it be necessary.

I put a Loopy VX-III 3.5 X 10 X 40 on the rifle that I had lying around Soon it was off to the range to test fire this newly restored Ruger No.1. Was I ever in for a pleasant surprise!!! I had some "cheap" factory ammo to test fire the gun with and some more pricey fodder to stuff in the barrel. When I looked through the spotting scope to check the first group I refused to believe my eyes!!! After four more groups were shot I had an aggregate group size that hovered at about ONE INCH! That's a no brainer... this rifle will be left as is, no re-barrel for this baby yet. Aw shucks, I'll just have to find another donor rifle for that re-barrel project.

I was pleased with the outcome of my project! You can judge for yourself from the pictures provided.

Whenever I frequent my area gun shops I like to look over their racks to see what they've bought or traded for. In February of 2008, low and behold I found a Ruger No.1, model 1-B in 30-06, on the used and abused rack. After fondling the rifle and examining the years of use and some abuse (mostly to the wood finish) I adopted this Ruger as my new pet for the mere sum of $325.00.

This rifle has a serial number prefix of #130, and from looking the number up on Ruger's website I found that the rifle was built late 1975 or sometime during early 1976. It is a pre-warning barrel but not a Liberty stamped barreled model. This serial number sequence does have the original and fully adjustable 3 screw trigger, that I adjusted to a very clean and crisp three pounds.

Originally I bought this rifle as a loaner or a donor rifle to re-barrel, thinking that this rifle as is might not shoot well due to old age and neglect. The finish on the wood looked scratched up and plain rough in a lot of places ..woof! The bluing was in fair shape except for what looked liked bloody fingerprints had removed. There sure was a lot of bore cleaning to do also!

While this Ruger hung out in my safe for a few months I contemplated what direction to take this rifle. The finish on this rifle had with age developed a sort of orange tint, and appeared to be "on the wood" instead of "in the wood." In the early 70's Ruger started using a spray polyurethane and that's why the finish had a glossy "on top" of the wood appearance.

I stripped off the old finish, sanded the stock, and gave the bare-naked wood a hand rubbed lovingly applied oil finish. I love the look and warmth of an oil finished rifle stock best AND they are so easy to repair should it be necessary.

I put a Loopy VX-III 3.5 X 10 X 40 on the rifle that I had lying around Soon it was off to the range to test fire this newly restored Ruger No.1. Was I ever in for a pleasant surprise!!! I had some "cheap" factory ammo to test fire the gun with and some more pricey fodder to stuff in the barrel. When I looked through the spotting scope to check the first group I refused to believe my eyes!!! After four more groups were shot I had an aggregate group size that hovered at about ONE INCH! That's a no brainer... this rifle will be left as is, no re-barrel for this baby yet. Aw shucks, I'll just have to find another donor rifle for that re-barrel project.

I was pleased with the outcome of my project! You can judge for yourself from the pictures provided.