Hondo44

Hawkeye

The first thing to check is to make sure the cyl lock in the bottom of the cyl window goes all the way down to allow the cyl to spin when you open the loading gate. If not, check that the loading gate spring tip (the big heavy 'V' shaped spring) is not sticking out to the front of where it pushes up on the loading gate shaft. If so, remove cyl and snap it back in place. Then replace cyl and see if it rotates properly.

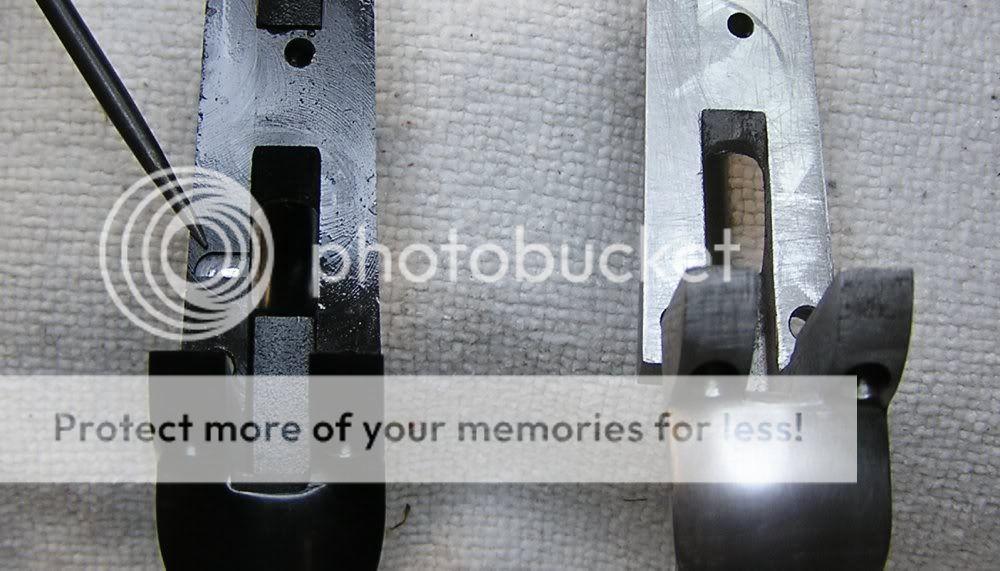

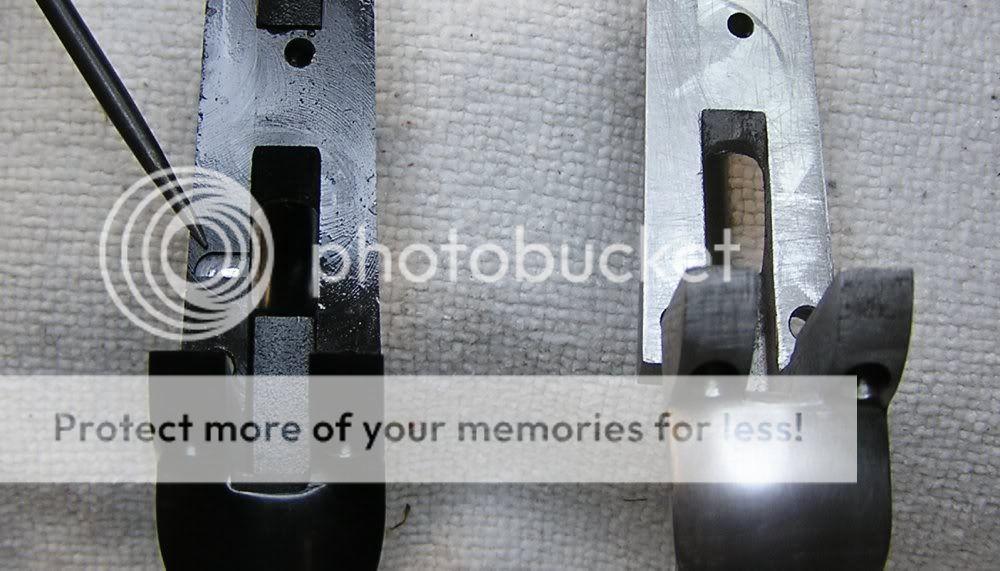

If that's not the issue, it's the cyl pawl. Take off the grip frame and look for a mark where the tit on the bottom end of the pawl contacts the top of the grip frame. Is the mark in the little relief cut you made in the grip frame like the white spot shown below on the grip frame on the left?

If you can't see a mark, coat the relief cut with a black indelible felt tip pen. Install the grip frame with only two screws; ones beside the hammer and the long one behind the trigger guard. Now cycle the action several times and open and close the loading gate several times.

Pull off the grip frame and check for the mark in the black ink. Is it in the relief cut? If yes, did you make the relief cut too deep or too shallow? Compare to relief cut in your original grip frame. Adjust relief cut accordingly.

If the mark is not in the relief cut, correct the cut so that it is. Assemble and recheck.

If that's not the issue, it's the cyl pawl. Take off the grip frame and look for a mark where the tit on the bottom end of the pawl contacts the top of the grip frame. Is the mark in the little relief cut you made in the grip frame like the white spot shown below on the grip frame on the left?

If you can't see a mark, coat the relief cut with a black indelible felt tip pen. Install the grip frame with only two screws; ones beside the hammer and the long one behind the trigger guard. Now cycle the action several times and open and close the loading gate several times.

Pull off the grip frame and check for the mark in the black ink. Is it in the relief cut? If yes, did you make the relief cut too deep or too shallow? Compare to relief cut in your original grip frame. Adjust relief cut accordingly.

If the mark is not in the relief cut, correct the cut so that it is. Assemble and recheck.