coop2564

Bearcat

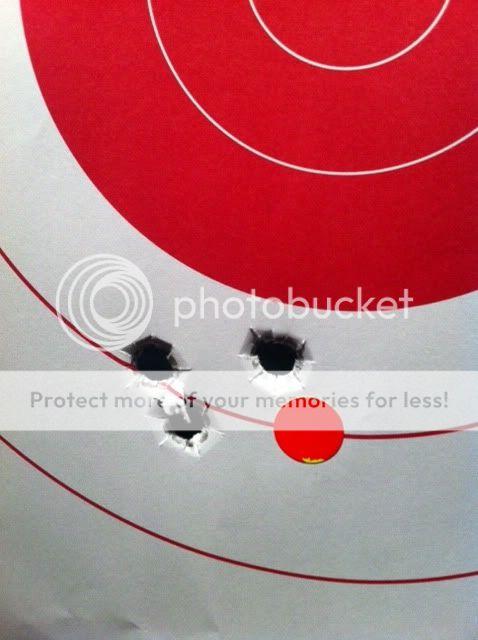

I have a NM BH 2007 model that best groups I can get are 3-4" from bench at 25yds, mostly 4". Having read older post I see where its common in 45 colt to have tight throats, so I took a .452 XTP last night after cleaning the cyl well and couldn't push thru, not even lightly tapping with end of screw driver. So im guessing if I want better than 4" in need to have it reamed. What are your thoughts and if someone has had it done did it improve accuracy and what is the cost? FYI I have done the DIY trigger job and its at 2.2lb but still slight creep, dont think its the problem.