TINCANBANDIT

Single-Sixer

- Joined

- Jan 3, 2014

- Messages

- 216

The charging handle was not the best looking one I have seen. I could have easily bought one for $30-$50, but some of those aftermarket ones add weight to the reciprocating assembly which can cause extraction issues.

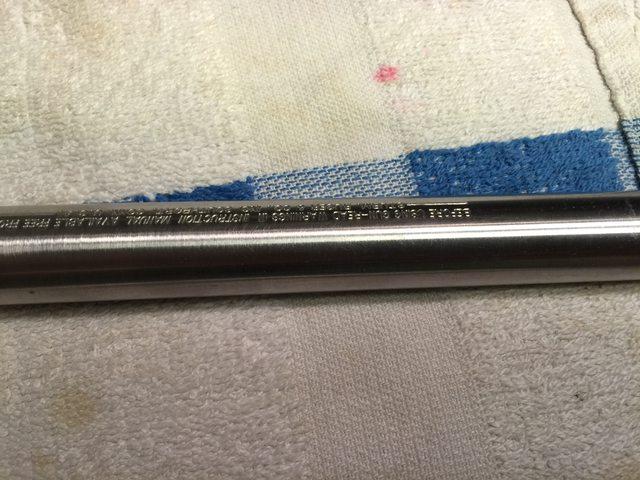

Here is what it looked like when I started, you can see the machine marks in the back of the handle

After removing the machine marks I polished it to a 600 grit

Then I did the same to the front

After polishing on the buffer

The handle is made of steel, so I will need to keep and eye on it and polish it from time to time.

Here is what it looked like when I started, you can see the machine marks in the back of the handle

After removing the machine marks I polished it to a 600 grit

Then I did the same to the front

After polishing on the buffer

The handle is made of steel, so I will need to keep and eye on it and polish it from time to time.