I recently had the pleasure of spending a couple afternoons talking bullets with Dick Thompson. What a fine gentleman. I regret that I didn't take any pics of the actual event(s), but I have some other photos of the bullets trapped in Imageshack that I'll post here when I figure out the hitch. I learned a ton and forgot about the camera!

Over the last year or so I have been slowly digesting the mountainous pile of casting info on sites like Castboolits and this one, while at the same time acquiring bit by bit the odd mold, pot or small batch of lead to eventually begin casting. I find it really interesting, a mix of physics alchemy and magic, and the knowledge base held by some guys out there is just off the charts. Dick is one of those guys and he is gracious enough to share what he knows, along with some great stories of how he came to know it.

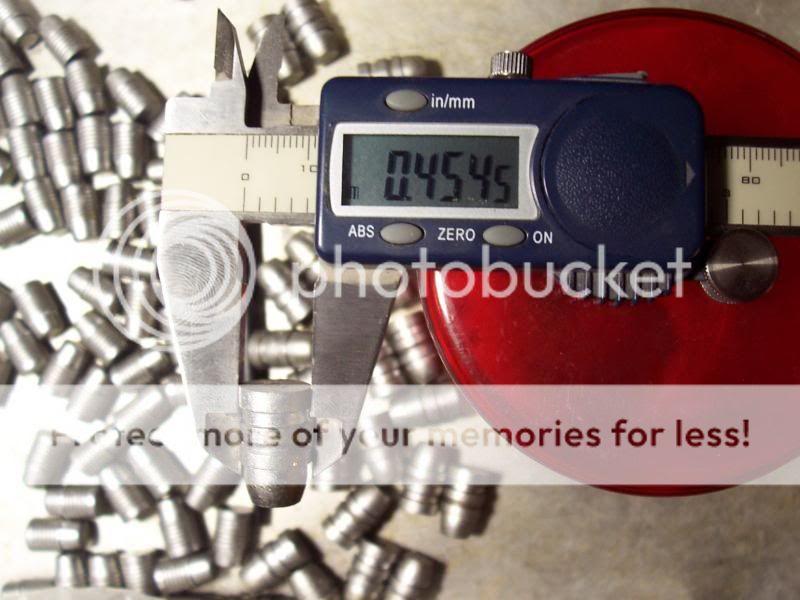

Through a series of pm's Dick had shared that he sized the bullets from an old Lyman 356402, a 120gr cone, at anywhere from .355 to .358 to fit the .380, 9mm, .38 Super and .38spl/.357mag. I really liked the idea of one mold serving multiple calibers and Dick offered to sell some of those bullets sized .356 and .358 to see how they shot in my guns. Since he Winters some here in AZ I was able to pick the bullets up and that's how I came to meet up with Dick.

The drive out to Wickenburg takes you through some beautiful featured desert terrain. Lots of ridges and vegetated gullies and the whole scape piling north toward the Bradshaws. It was a lovely day for the drive and after about 4 phone calls and as many laps through oldtown (lost ) I finally arrived at Dick's place. We greeted and chatted around the bench out front and I felt immediately welcomed. We talked bullets and casting to your load and he showed me around his Star Lube Sizer, effectively dashing my pan lube plans right into the rocks haha. What a neat machine. Wish I'd never seen one haha. Dick invited me to come by anytime and he'd load up a pot and teach me to cast. I accepted that invitation!

) I finally arrived at Dick's place. We greeted and chatted around the bench out front and I felt immediately welcomed. We talked bullets and casting to your load and he showed me around his Star Lube Sizer, effectively dashing my pan lube plans right into the rocks haha. What a neat machine. Wish I'd never seen one haha. Dick invited me to come by anytime and he'd load up a pot and teach me to cast. I accepted that invitation!

Going inside I met Dicks lovely wife and got to check out some baskets that she had woven largely out of pine needles. Wow! What a talent! There were pieces of cross sectioned walnut shell woven in and one had an antler woven into its base. It is one of the things I wish I took a picture of as words don't do it justice. Beautiful. We sat and Dick broke out a photo album with lots of hunting pics and stories. In one pic Callshot was grinning over a big moose. In another Dick's sons were posed with a couple of bucks that would be in the running at any Cabelas beauty pageant.

Other highlights of the day were trying on the Barranti Northwest Hunter rig #01 (feels/fits great!) and handling the 2DXD and Sixshot's .327 Blackhawk. He had some .327 Sledgehammer slugs loaded up and we checked them for fit in the cylinder of my SP101. Plenty of room.

Dick gave me a handful of the Sledgehammers to try in the SP. I believe those hollow point slugs were cast in 2 parts and were loaded over 12-ish gr H110. They later shot great through my 101! As I left we made loose plans to cast some Sledgehammers the next week and I drove home with a head full of information to ponder.

2Dogs' design .327 Sledgehammer w/ 100gr RN, 85gr Hydra Shock and 385gr HP .475 for luck

The next week I drove back up with some wheel weight ingots and Dick plugged in his Lee pot and walked me through the whole process. This thread is getting pretty long winded, but to cut to the quick of it, Dick showed me how to lube and care for my molds and how to handle them properly to avoid damage. We talked about mixing your alloy to match your intended load, about water quenching ww alloy for a hardness @ 20 and how you could reheat ww bullets up to @ 400f for a spell and then water drop them for a hardness @ 15. We discussed the reasons and options for fluxing and talked about managing heat and timing for both mold and pot to get your bullets to drop just right. We talked about the pros and cons of sizers and the ups and downs of tumble lubing and doing things on the cheap etc etc. Throughout the day Dick patiently explained everything and never seemed in a hurry. Safety was always addressed and several times as a question came to my mind he would already be touching on the answer. The info flowed quite naturally. I had a fantastic time and was casting some myself by the end of it all. What a treat. We mounted the Star to the bench and sized/lubed them up right then and there. Dick was an excellent teacher and host and the day just flew by. Again I drove back home with a head full of details and 184 250gr WFN bullets for my 41's.

Not much neck tension left in this brass

Since then I have fired up my pot 3 times, have broken in my molds and am learning more every time I sit down to it. Casting is really fulfilling and I am so stoked to be learning.

MP 41 #258 mold drops 225gr slugs. These are slightly different than LAH's 41-230-K slug. Top row cold rejects, middle decent, bottom row frosting up.

MP 41 #258 225gr and MP 45-270-SAA 285gr

A huge and hearty THANK YOU to Sixshot for taking the time to school me. It was a pleasure learning from you and I'll always appreciate that. My gear and whole neighborhood is safer for your time. Hope we can do it again sometime Dick and then go shoot 'em! Cheers buddy!!

Over the last year or so I have been slowly digesting the mountainous pile of casting info on sites like Castboolits and this one, while at the same time acquiring bit by bit the odd mold, pot or small batch of lead to eventually begin casting. I find it really interesting, a mix of physics alchemy and magic, and the knowledge base held by some guys out there is just off the charts. Dick is one of those guys and he is gracious enough to share what he knows, along with some great stories of how he came to know it.

Through a series of pm's Dick had shared that he sized the bullets from an old Lyman 356402, a 120gr cone, at anywhere from .355 to .358 to fit the .380, 9mm, .38 Super and .38spl/.357mag. I really liked the idea of one mold serving multiple calibers and Dick offered to sell some of those bullets sized .356 and .358 to see how they shot in my guns. Since he Winters some here in AZ I was able to pick the bullets up and that's how I came to meet up with Dick.

The drive out to Wickenburg takes you through some beautiful featured desert terrain. Lots of ridges and vegetated gullies and the whole scape piling north toward the Bradshaws. It was a lovely day for the drive and after about 4 phone calls and as many laps through oldtown (lost

Going inside I met Dicks lovely wife and got to check out some baskets that she had woven largely out of pine needles. Wow! What a talent! There were pieces of cross sectioned walnut shell woven in and one had an antler woven into its base. It is one of the things I wish I took a picture of as words don't do it justice. Beautiful. We sat and Dick broke out a photo album with lots of hunting pics and stories. In one pic Callshot was grinning over a big moose. In another Dick's sons were posed with a couple of bucks that would be in the running at any Cabelas beauty pageant.

Other highlights of the day were trying on the Barranti Northwest Hunter rig #01 (feels/fits great!) and handling the 2DXD and Sixshot's .327 Blackhawk. He had some .327 Sledgehammer slugs loaded up and we checked them for fit in the cylinder of my SP101. Plenty of room.

Dick gave me a handful of the Sledgehammers to try in the SP. I believe those hollow point slugs were cast in 2 parts and were loaded over 12-ish gr H110. They later shot great through my 101! As I left we made loose plans to cast some Sledgehammers the next week and I drove home with a head full of information to ponder.

2Dogs' design .327 Sledgehammer w/ 100gr RN, 85gr Hydra Shock and 385gr HP .475 for luck

The next week I drove back up with some wheel weight ingots and Dick plugged in his Lee pot and walked me through the whole process. This thread is getting pretty long winded, but to cut to the quick of it, Dick showed me how to lube and care for my molds and how to handle them properly to avoid damage. We talked about mixing your alloy to match your intended load, about water quenching ww alloy for a hardness @ 20 and how you could reheat ww bullets up to @ 400f for a spell and then water drop them for a hardness @ 15. We discussed the reasons and options for fluxing and talked about managing heat and timing for both mold and pot to get your bullets to drop just right. We talked about the pros and cons of sizers and the ups and downs of tumble lubing and doing things on the cheap etc etc. Throughout the day Dick patiently explained everything and never seemed in a hurry. Safety was always addressed and several times as a question came to my mind he would already be touching on the answer. The info flowed quite naturally. I had a fantastic time and was casting some myself by the end of it all. What a treat. We mounted the Star to the bench and sized/lubed them up right then and there. Dick was an excellent teacher and host and the day just flew by. Again I drove back home with a head full of details and 184 250gr WFN bullets for my 41's.

Not much neck tension left in this brass

Since then I have fired up my pot 3 times, have broken in my molds and am learning more every time I sit down to it. Casting is really fulfilling and I am so stoked to be learning.

MP 41 #258 mold drops 225gr slugs. These are slightly different than LAH's 41-230-K slug. Top row cold rejects, middle decent, bottom row frosting up.

MP 41 #258 225gr and MP 45-270-SAA 285gr

A huge and hearty THANK YOU to Sixshot for taking the time to school me. It was a pleasure learning from you and I'll always appreciate that. My gear and whole neighborhood is safer for your time. Hope we can do it again sometime Dick and then go shoot 'em! Cheers buddy!!