I'm kinda surprised to see this kind of response here. Guys weld stainless every day - I have a staff of 104 fitters and welders under me alone that do it EVERY DAY...

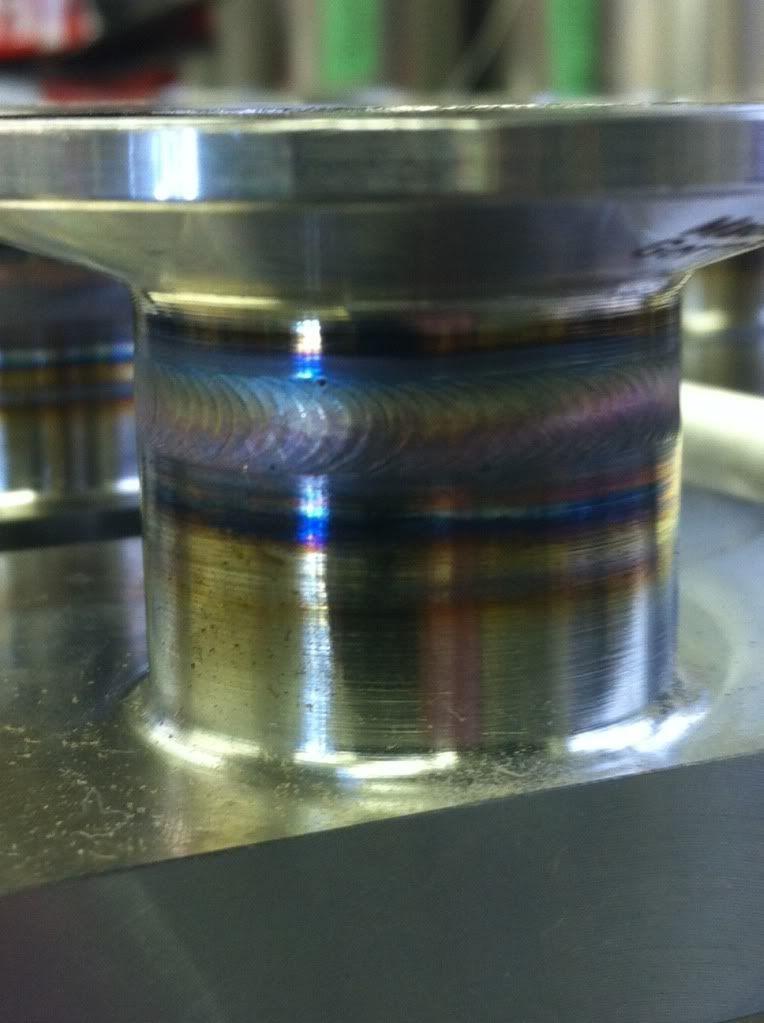

It's a bit more complicated than welding carbon steel, and there's certainly no reason for a guy like Hamilton Bowen to take on a job like that when he keeps his calendar full with "standard" customization work, but welding stainless steel isn't prohibitively onerous. I'm a TERRIBLE welder compared to my guys, but they showed me some of the tricks and I've done a bit of stainless welding with success. Ruined ONE ruger grip frame, but worked on the other. If you knock out the temper, you just gotta retemper it. From what I understand (and experienced first hand) if it's going to crack from improper heating, it's probably going to do so right away. Having access to industrial Xray 'proofing' equipment helps, of course, to prove that things are in order before you put load on them. The bigger challenge, that the boys are telling me at least, would be knowing the exact alloy that Ruger uses in their frames. Knowing that, they're telling me it'd be no sweat.

"Sooting" from the weld is a matter of polishing afterwards. No big deal compared to the weld and reprofiling job itself.