20 August 2019

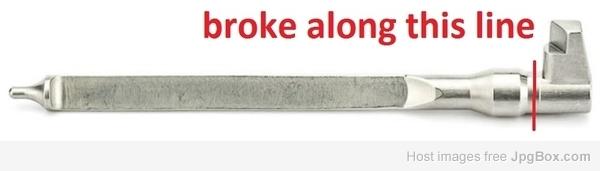

I just installed a new Glend Arms firing pin in my Mini-14.

I found a website which said, "The factory will fit one with .020" protrusion, but for absolute reliability, .025" or .030" is superior."

I did some filing-to-length and the maximum measured protrusion on the new pin is now .027". Yesterday I did 100 rounds of test fire, no problems.

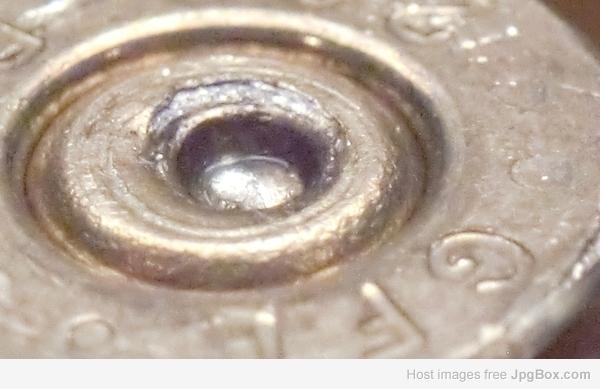

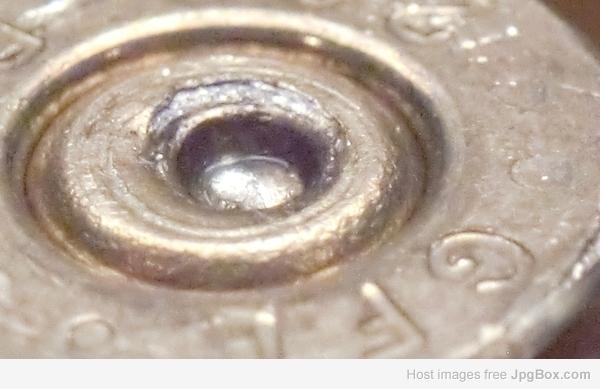

Here's some pictures of the dimple in the primer, does this seem excessive ?? I have no experience with "how deep is too deep" and would welcome some insight.

.

I just installed a new Glend Arms firing pin in my Mini-14.

I found a website which said, "The factory will fit one with .020" protrusion, but for absolute reliability, .025" or .030" is superior."

I did some filing-to-length and the maximum measured protrusion on the new pin is now .027". Yesterday I did 100 rounds of test fire, no problems.

Here's some pictures of the dimple in the primer, does this seem excessive ?? I have no experience with "how deep is too deep" and would welcome some insight.

.