Yes it can and fairly easily. The RIPSystem is a simple retrofit:

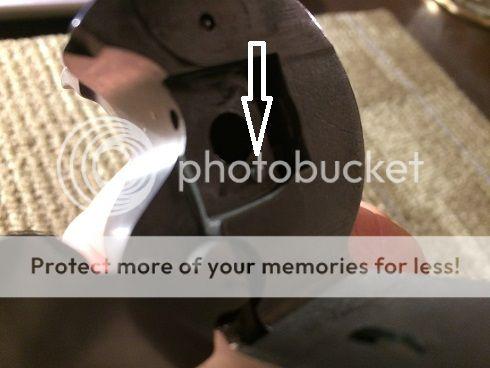

You can see the device (3 parts) in the recoil shield to the lower left of the cyl pin hole shown below:

Photo by Hossbreed44.

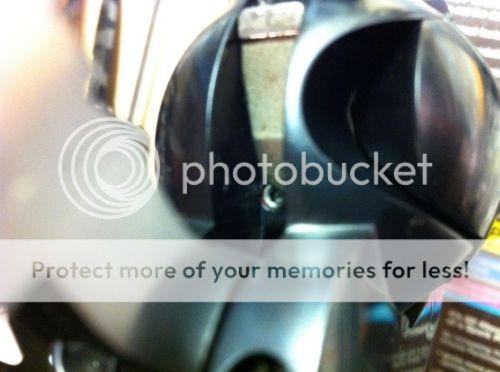

Hex retaining screw in hammer channel for spring and indexing pawl button:

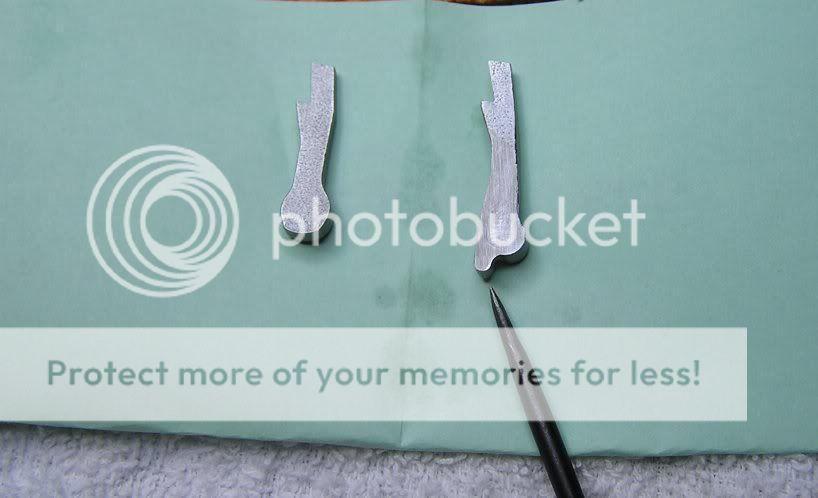

Ruger free spin pawl on the right:

Divot for free spin pawl shown on the left used on NM Flat Tops and New Vaqueros with the reverse indexing system using the Ruger free spin pawl:

Other related notes:

1. The NM BH with more than 6 chambers and Single 7 aren't necessarily designed to align the chambers at the click, but they do because of their different # of chambers 'geometry':

On the .327 BH, because of the eight holes with large loading chute and small cartridges, it also works.

On the .22 S7 because of the 7 holes in the small cyl it can also work when the loading chute is properly shaped but it's a closer fit.

2. Most S7s line up as they come. But the final shaping and polishing of the loading chute is done by hand so they vary. Ruger fixes the ones that don't align: on the side of the loading chute where the rim drags, they do a slight fitting improvement and re-polish. Most owners do it themselves.

It's a simple installation that any smith or anyone can do that can drill a hole and tap threads.

Needed is two drill sizes and a tap: basically drill one hole thru the hammer channel, counter drill the same hole with a smaller drill and tap threads in the counter drilled hole only. It helps to have a gun with it, to determine exact location to drill, hole sizes and depth.

You'll need to "free spin" the regular cyl pawl the 5 minute way described in #1 below Or purchase and install Ruger's or Power Customs free spin cyl pawl for another $30 or so, #2 below.

If you do #1 below you do not need to purchase the Ruger pawl or modify the trigger guard under the frame.* Just purchase and install three little parts listed below by their correct Ruger names that comprise the New Vaq and NM Flat Top Blackhawk cylinder alignment indexing pawl. $10 in parts, must have skill to drill small hole and tap threads in the hole. Refer to a New Vaquero or Flat Top Blackhawk for the proper location and size of the hole.

"Reverse Indexing Pawl System" parts:

Names of parts, Ruger Part #s & Brownell Part #s (about $15 total)

Ejector/chamber Alignment Pawl (not to be confused with the Cyl pawl)………..KMVQ04502….780-001-292ah

Cylinder rotation Stop Spring……………………………………………………………………………..KMVQ04500….780-001-293ah

Cylinder Rotation Alignment Pawl & Spring Retention Screw…………………………….KMVQ04501….780-001-294ah

Free spin cyl pawl* (for mid/large size frame only)……………………………………………KMVQ00701….780-001-296WB

*must modify existing pawl or use Power Custom pawl for single six frame size.

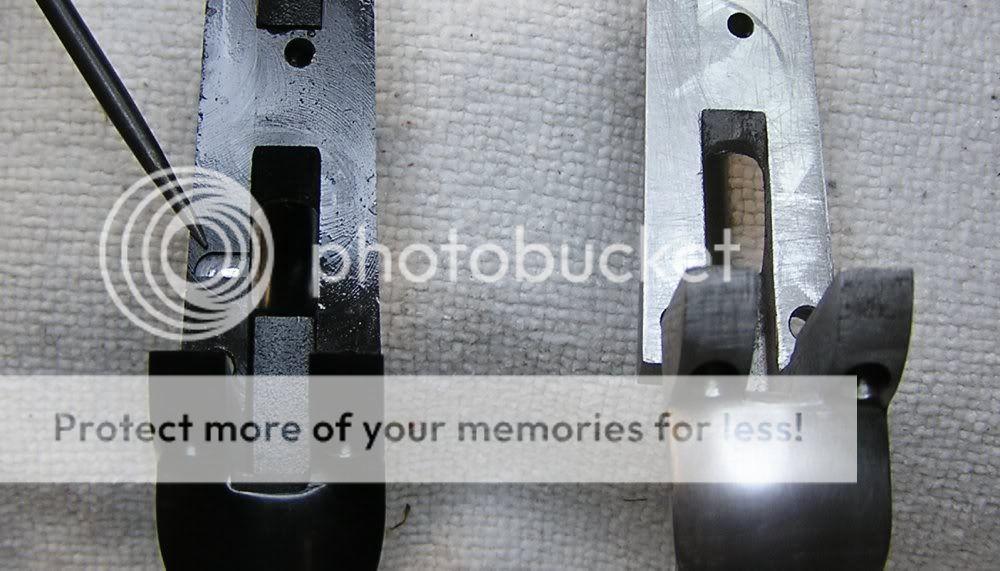

If you choose to use a Ruger free spin pawl, here's how I cut the divot. Use a thin cut-off blade in a Dremel tool. With grip frame in a vice, and your old grip frame nearby for reference, hold the Dremel with two hands for control. And replicate the divot in the new grip frame. Be cautious not to let the cut extend to the outside edge of the trigger guard strap or it will show when assembled. You can also clamp the Dremel tool in the vice at an angle and hold the trigger guard strap instead.

Simpler solution alternatives with or w/o using the Ruger RIPS parts:

If you do this in conjunction with Solution #1 or #2 below, you will not need to order and fit a new Ruger free spin cylinder pawl or grind a needed small divot in the top of the trigger guard strap (under the frame) required for the factory cyl pawl. Cylinder chambers will align with loading gate opening exactly like the New Vaq., NM Flat Tops and the Old Models.

Solution 1. Modify your pawl to a free wheel cylinder pawl. No cost and almost no skill required (also see FAQs below):

http://marauder.homestead.com/files/FreeSpin.html

Your cylinder will freewheel in both directions with loading gate opened. The most immediate benefit of course for New Models is proper alignment of the chamber with the loading gate opening for loading/unloading. But there are additional benefits: if you have a round that might have a high primer before or after firing, pulled bullet from recoil, or other problem that makes the cylinder tight to turn, you don't have to pull the cylinder with live round in it to unload it. It's much safer to just turn the cylinder in reverse and unload problem rounds thru the loading gate. Therefore, I free spin Old Models as well. I prefer this to solution #2.

Solution 2. Install a Power Custom replacement 1/2 cock hammer about $125. By cocking the hammer to 1/2 cock the NMs will work just like OM Rugers by aligning the chamber and loading gate. You can also do this on New Vaq and NM Flat Tops if you want them to operate the same as Old Models. You can also purchase the entire Powers kit: hammer, trigger, pawl and transfer bar; see their website.

Why don't all New Model Rugers have this system???

Only the New Vaqueros and NM Flat Top Blackhawks introduced in 2005 added the Reverse Indexing Pawl System (RIPS). Their machining/production lines were designed and set up to include the RIPS. But existing model production lines are not and very expensive to reprogram/change, not to mention the production downtime required while all that takes place.

The 2019 .22 Wrangler has an economy version with just a free spin cyl pawl.