VictorLouis said:

The .44 Special aligns the chamber on the click. The .45 Colt does not, just like a SBH. Is that normal? Is it a function of the larger bore diameter?

Yes that's normal.

No it's not a function of the larger bore diameter.

You're comparing to different action designs, see below.

Why some New Models chambers align and some don't:

New Model Rugers are designed for loading/unloading with the hammer down. It's a safety feature of the NM transfer bar safety system that does not allow the hammer to be half cocked for loading.

Therefore the cyl pawl is not properly located to click when the cyl chambers are aligned with the loading chute. All of the New Models (except Bearcat) are designed so the hammer can't be brought to half cock for loading/unloading and there is no half cock notch on the hammers, therefore the cyl pawl isn't moved and the cyl doesn't get positioned to line up the chambers with the loading trough when loading/unloading the cyl.

As you know on the OMs the hammer is on half cock for loading/unloading which positions the cyl pawl properly to click and stop reverse rotation of the cyl which aligns the chambers with the loading chute.

That's why Ruger has designed the Reverse Indexing Pawl System (RIPS) for new medium and large frame single action products since 2005; the Flat top BHs and New Vaqueros. The Wrangler small frame has a simple free spin cyl.

NOTE and just FYI: After market hammers with a half cock notch are available for New Models from Power Custom. The transfer bar loading gate/hammer lockout is modified so the hammer can be cocked to the half cock position and therefore the chambers do align at the click.

Also the Reverse Indexing Pawl System can be installed in any NM Ruger.

Only the New Vaqueros and NM Flat Top Blackhawks introduced in 2005 added the Reverse Indexing Pawl System (RIPS). Their machining/production lines were designed and set up to include the RIPS. But existing model production lines are not and very expensive to reprogram/change, not to mention the production downtime required while all that takes place.

The 2019 .22 Wrangler has a free spin cyl.

But the good news is that the RIPSystem is a simple retrofit as well:

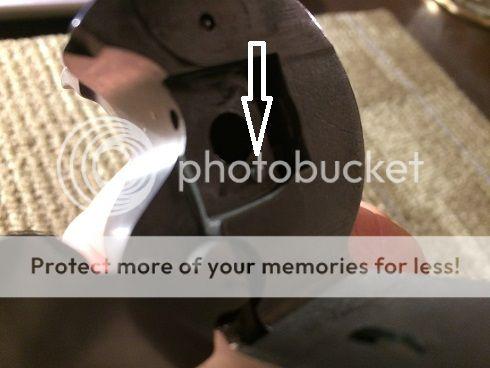

You can see the device (3 parts) in the recoil shield to the lower left of the cyl pin hole shown below:

Photo by Hossbreed44.

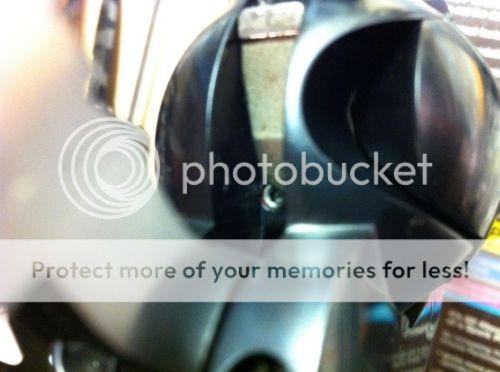

Hex retaining screw in hammer channel for spring and indexing pawl button:

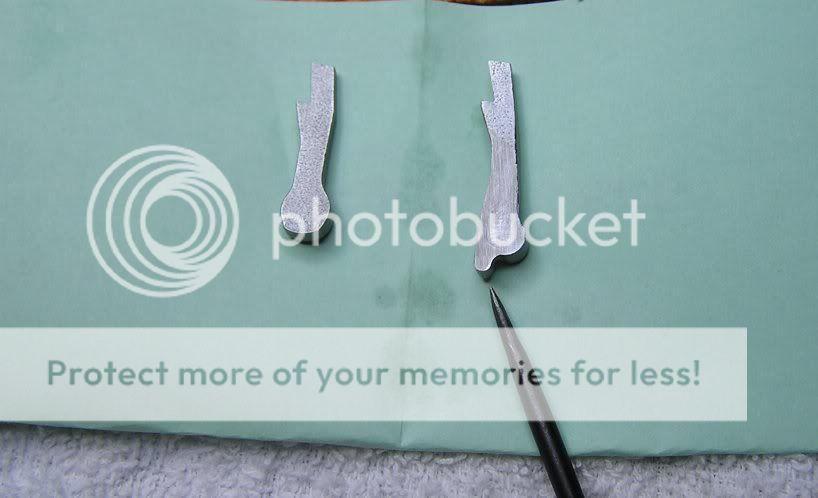

Ruger free spin pawl on the right:

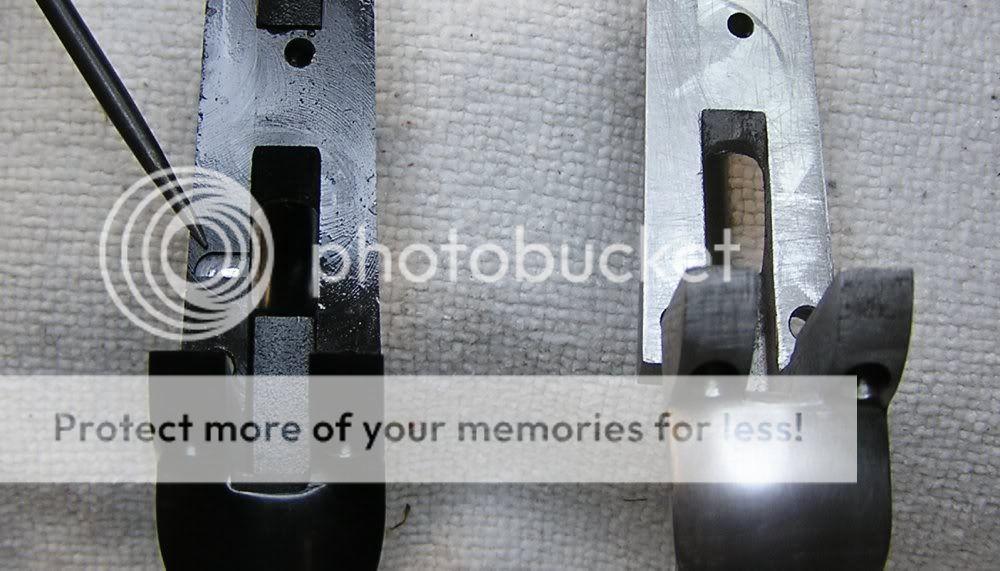

Divot for free spin pawl shown on the left used on NM Flat Tops and New Vaqueros with the reverse indexing system using the Ruger free spin pawl:

Other related notes:

1. The NM BH with more than 6 chambers and Single 7 aren't necessarily designed to align the chambers at the click, but they do because of their 'geometry":

On the BH because of the eight holes with large loading chute, it works.

On the S7 because of the 7 holes in the small cyl it can also work when the loading chute is properly shaped but it's a closer fit.

2. Most S7s line up as they come. But the final shaping and polishing of the loading chute is done by hand so they vary. Ruger fixes the ones that don't align: on the side of the loading chute where the rim drags, they do a slight fitting improvement and re-polish. Most owners do it themselves.

I hope that helps,