Lee Martin

Hunter

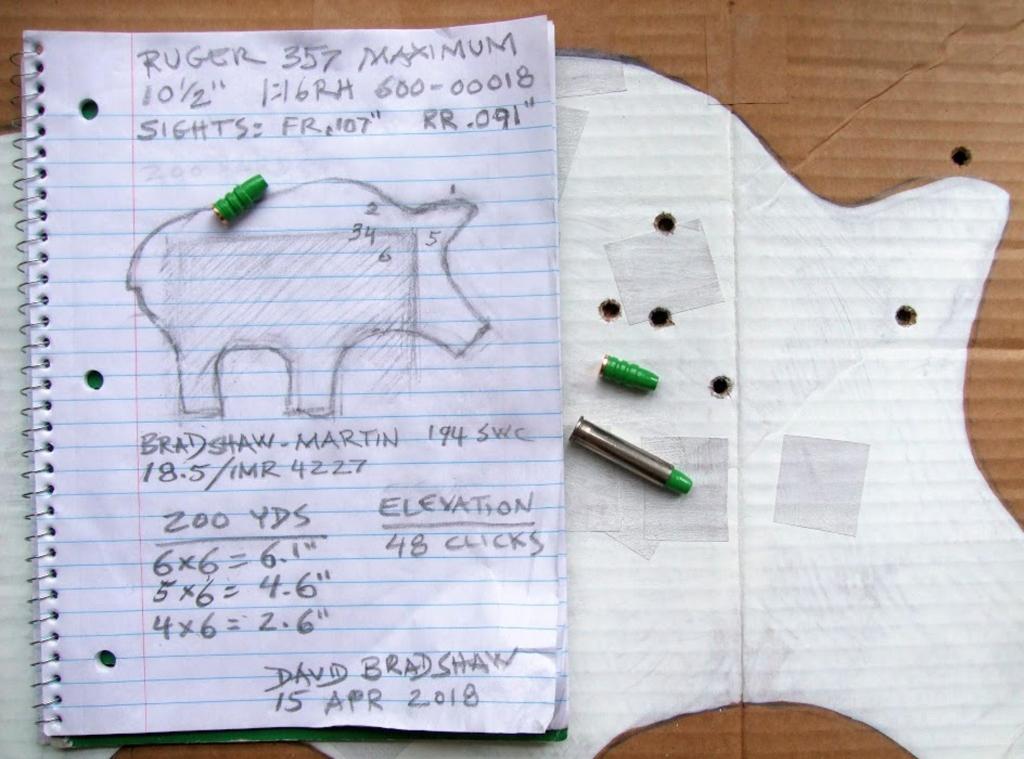

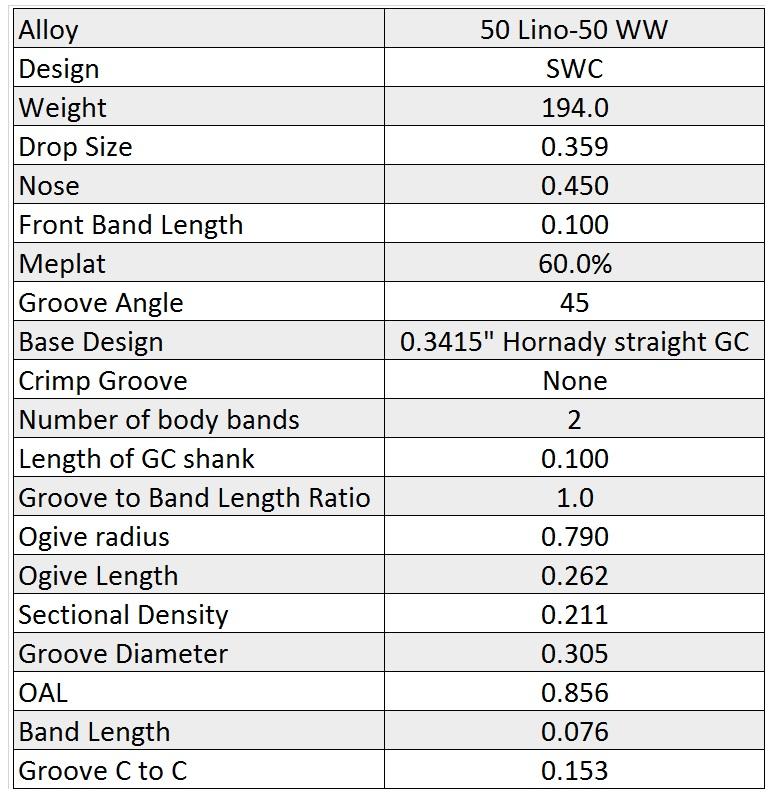

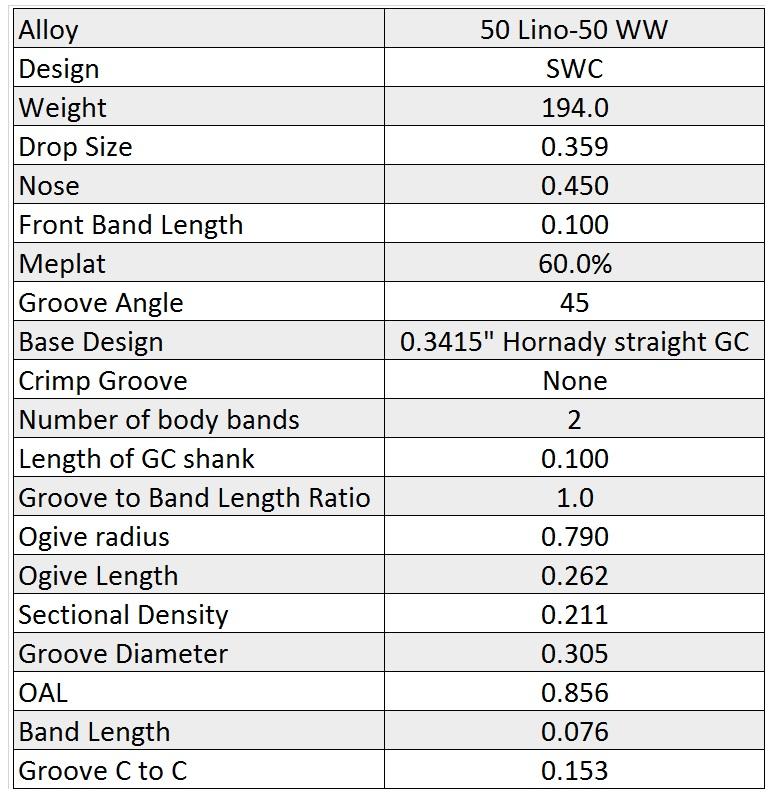

Over the past 7 years, David Bradshaw and I have amassed a few hundred hours of phone conversation. Predictably, a large part of that time has centered on the .357 Maximum. David was pivotal in the development of the cartridge and the gun. He worked alongside Bill Ruger Sr. and Jr. to make the Maximum a reality. I had an affinity for the Max long before meeting Bradshaw. In December 2017, I decided to commemorate his involvement with a special project. It began by me asking him a simple question – "if you were to design a bullet specifically for the Ruger Maximum, what would it be?" A half-dozen conversations later, the 194 grain Bradshaw-Martin SWC GC was born. The specifications are shown below. Let me add, the design was not casually landed on. David put a lot of thought into the bullet we're now introducing. In January I placed an order with Mountain Molds. Six days later it was on my doorstop. Tip of the hat to Dan for this outstanding 2-cavity block.

The Mountain Mold:

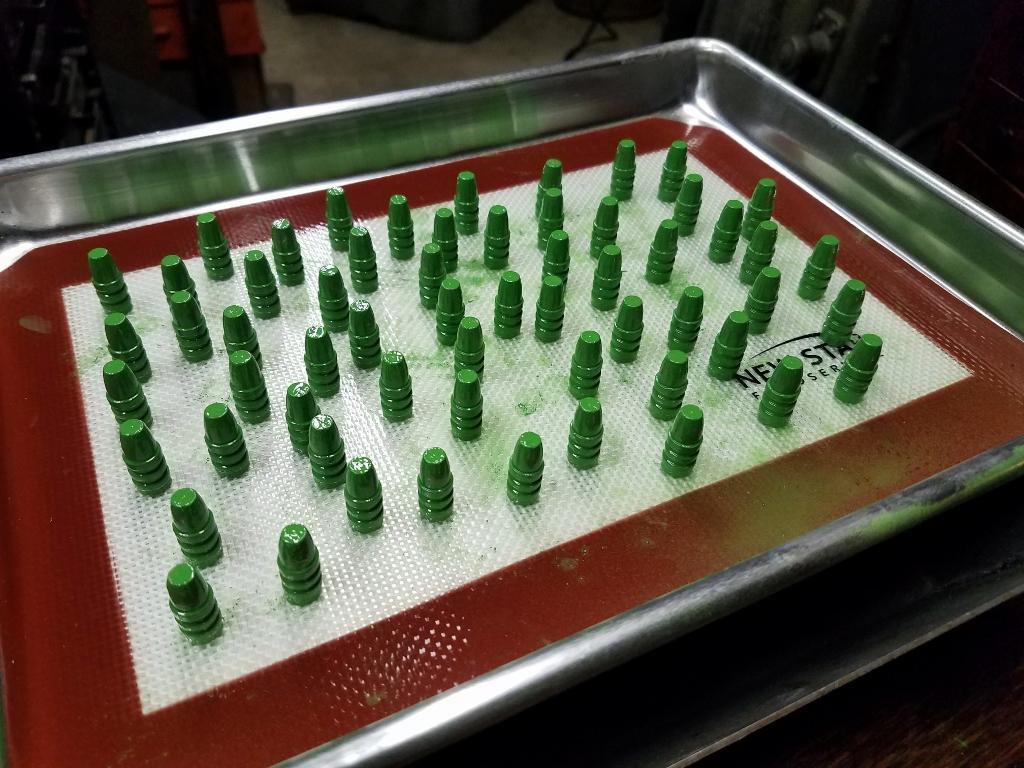

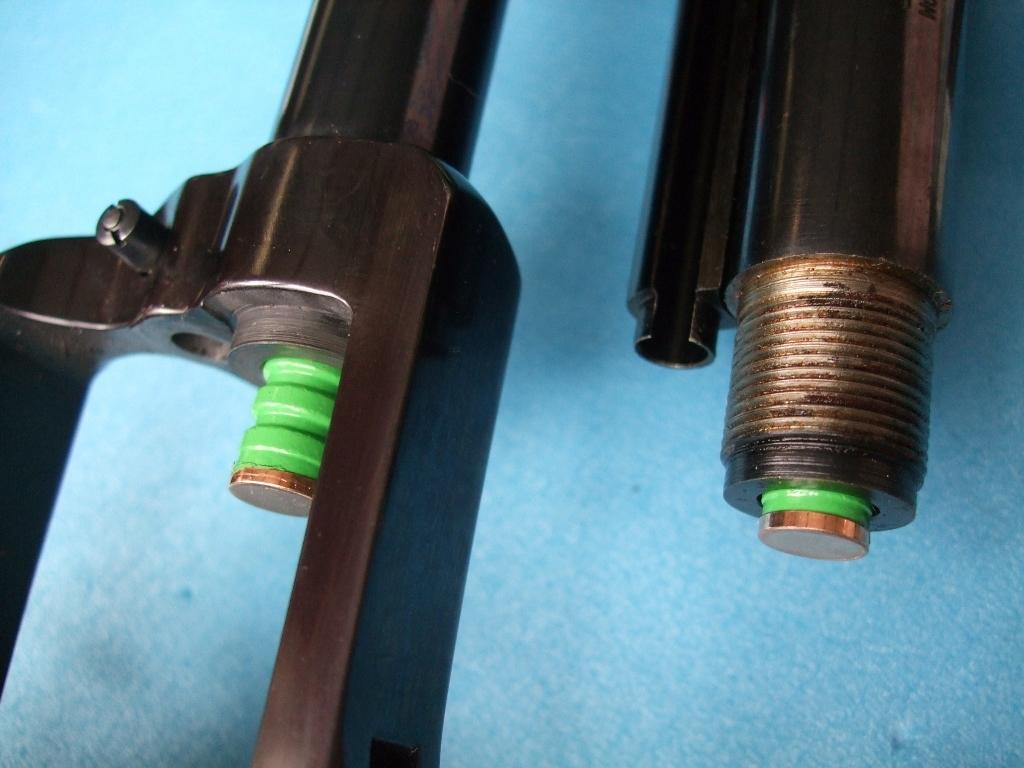

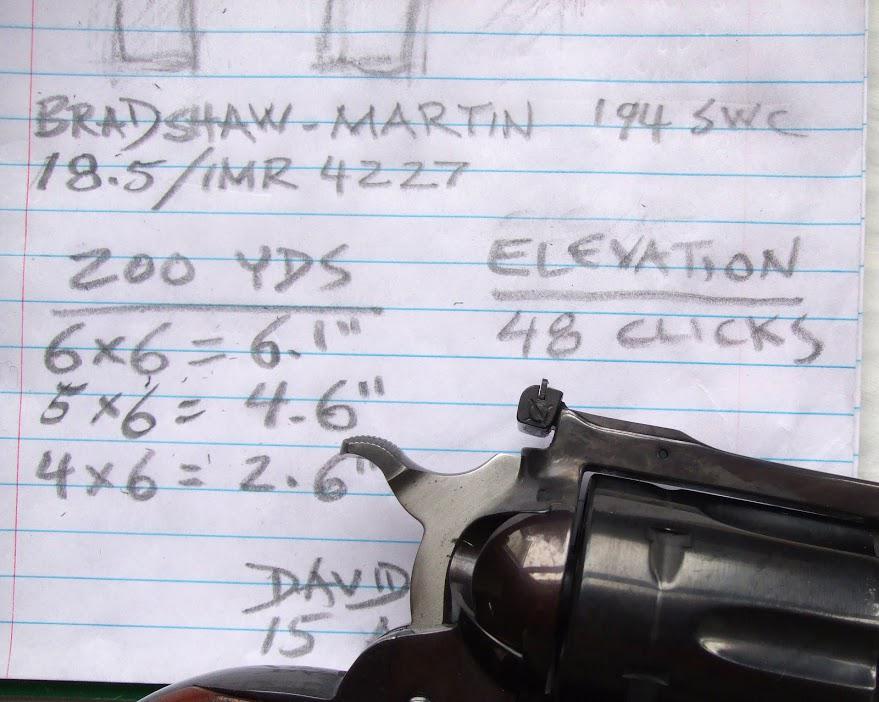

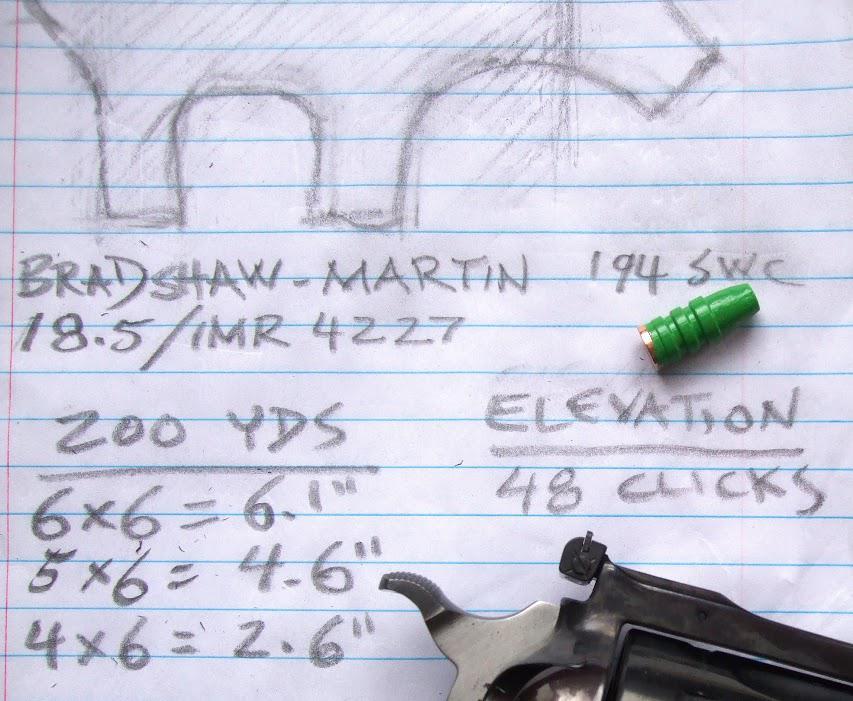

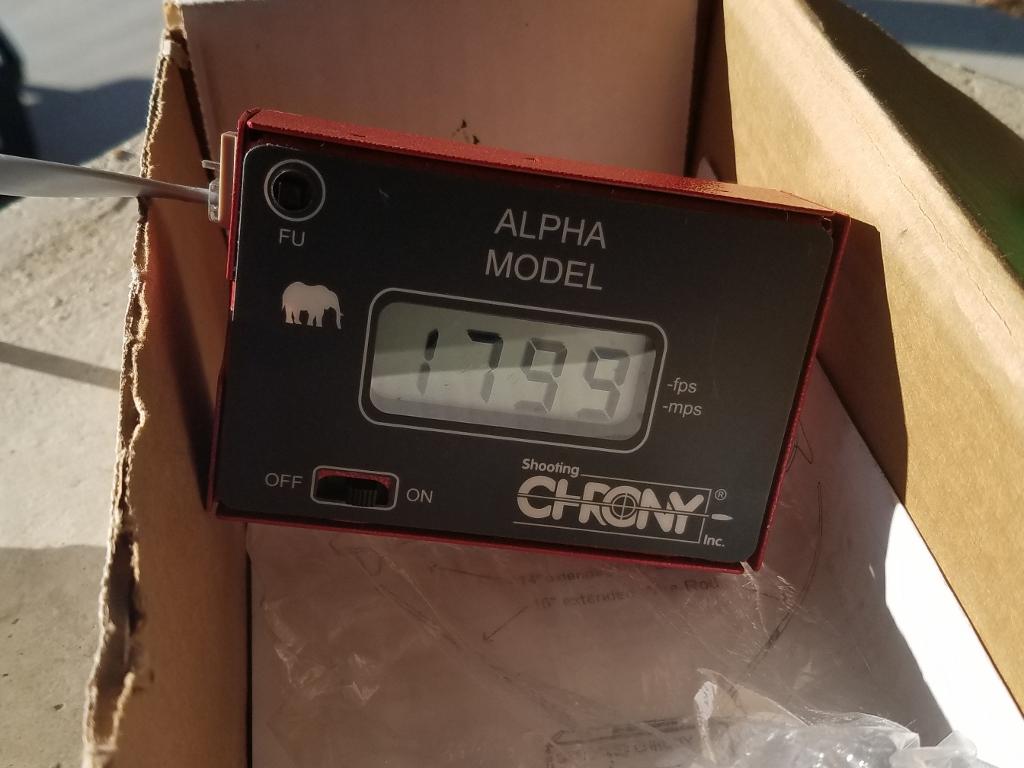

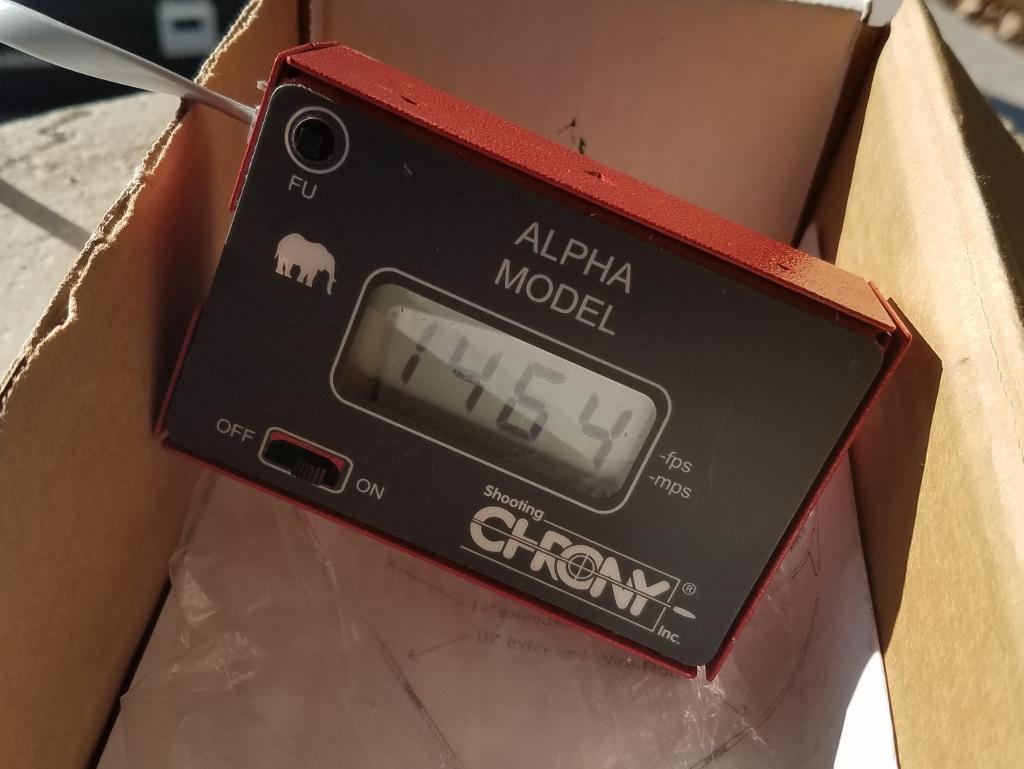

So far I've cast around 1,000 of these, all from 25-1 lead/tin alloy. The powder coating is Eastwood's brand lime green, gas-checked with Hornady straights. David and I agreed to publish this after the bullet was tested at 100 and 200 yards. Those results will be shared in subsequent posts. It's only fitting that I now turn the thread over to David. He'll explain the 'why' behind the 194 gr Bradshaw-Martin SWC GC.

The Mountain Mold:

So far I've cast around 1,000 of these, all from 25-1 lead/tin alloy. The powder coating is Eastwood's brand lime green, gas-checked with Hornady straights. David and I agreed to publish this after the bullet was tested at 100 and 200 yards. Those results will be shared in subsequent posts. It's only fitting that I now turn the thread over to David. He'll explain the 'why' behind the 194 gr Bradshaw-Martin SWC GC.