Lee Martin

Hunter

I started documenting a 5-shot conversion on my forum and thought the Ruger crowd may be interested too. Just like my OM .44 Special and Buffalo Seville, I'll cover each and every step in doing one.

As I've gotten older, I've fallen out of love with barrel bands on revolvers. Used to adore bands, but now my eyes don't take to them. Plus my preferred barrel length on Blackhawks is 6.0". The conversion will be the sister gun to this .500 Linebaugh:

The differences will be:

1) 6.0" straight taper barrel

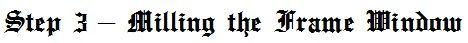

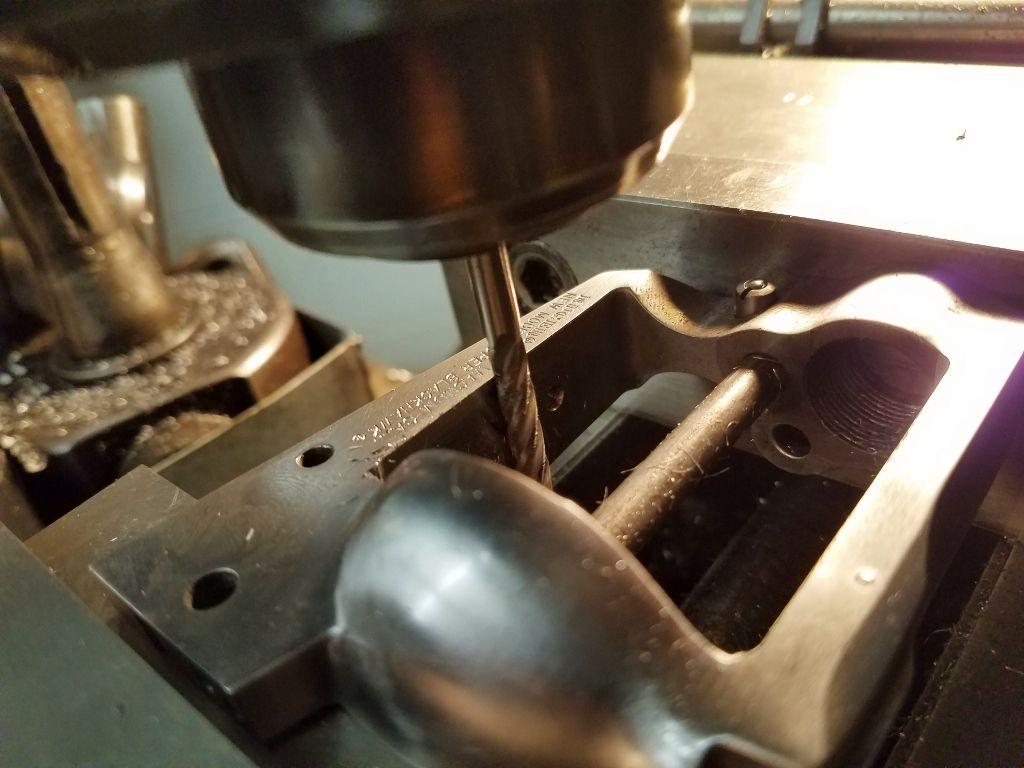

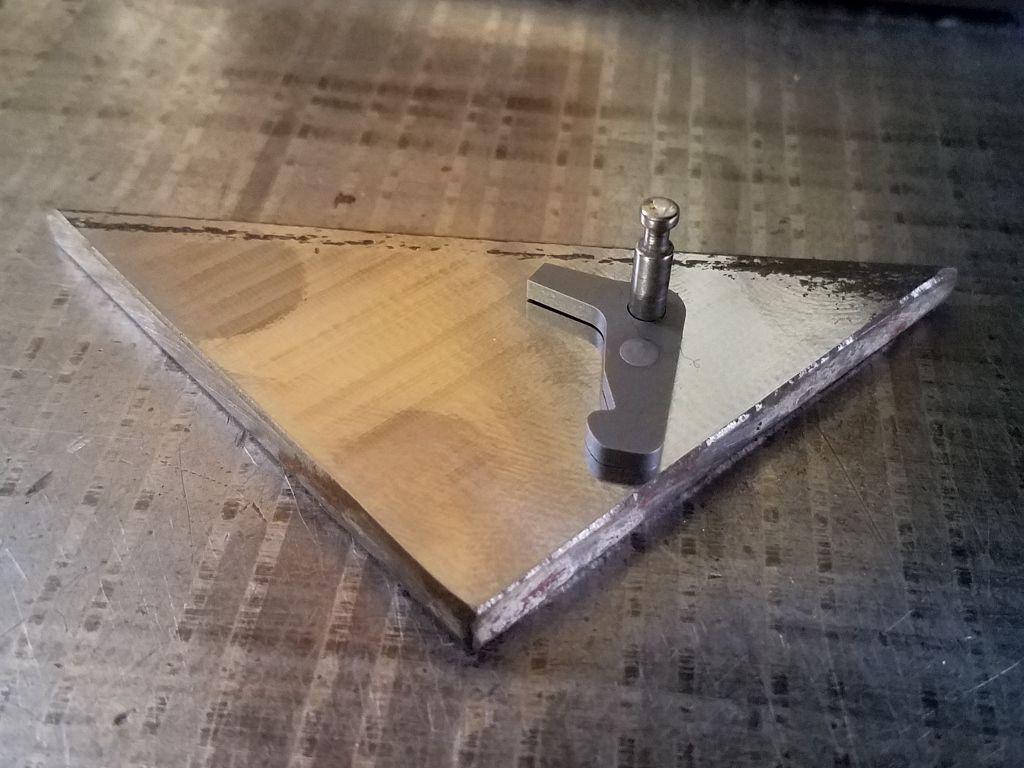

2) Frame window opened 0.060"

3) Recessed cylinders (not a huge fan of them, but will do so here)

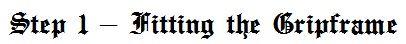

4) Jack Huntington Bisley mod with walnut panels

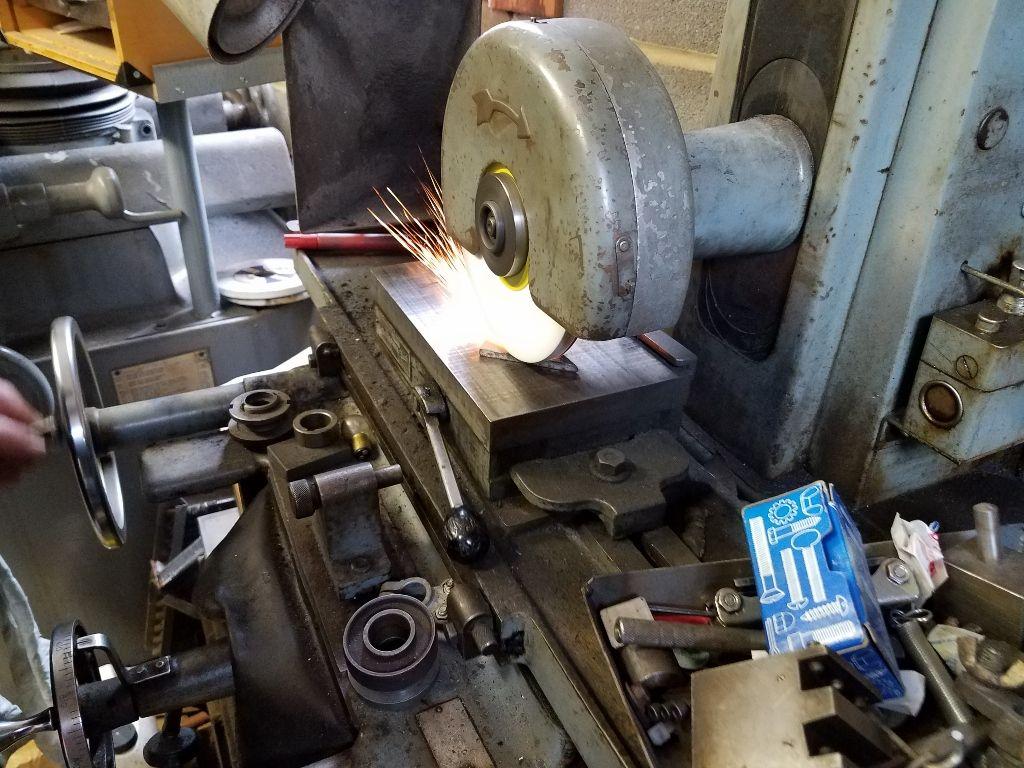

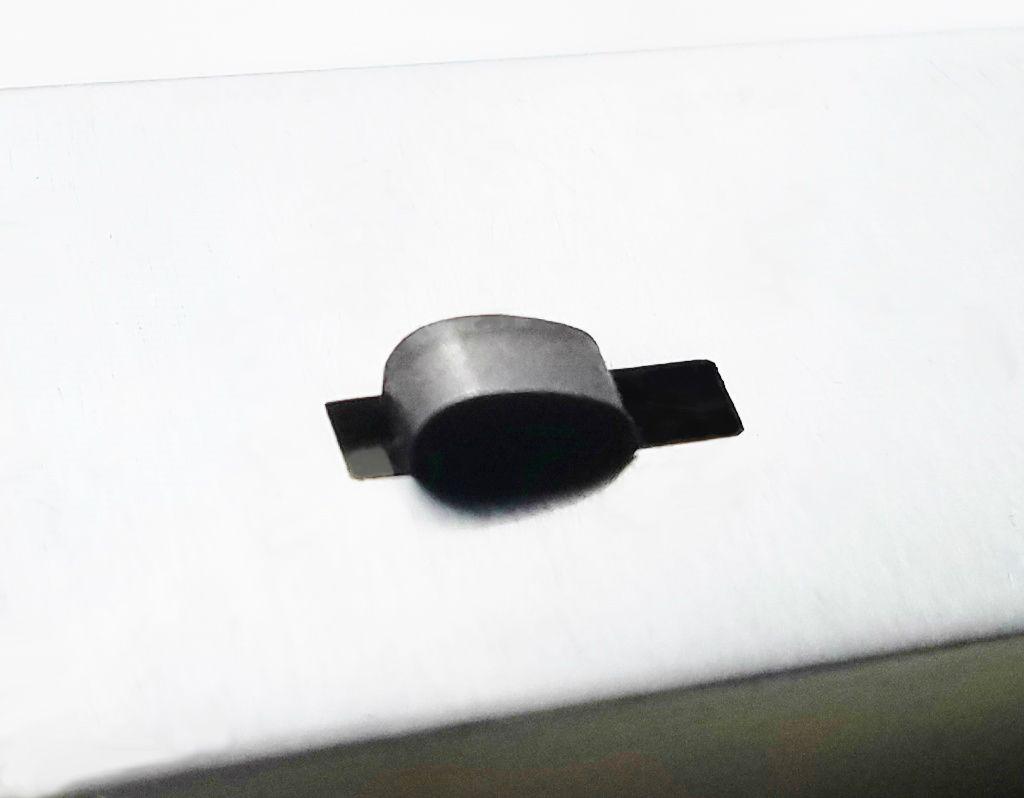

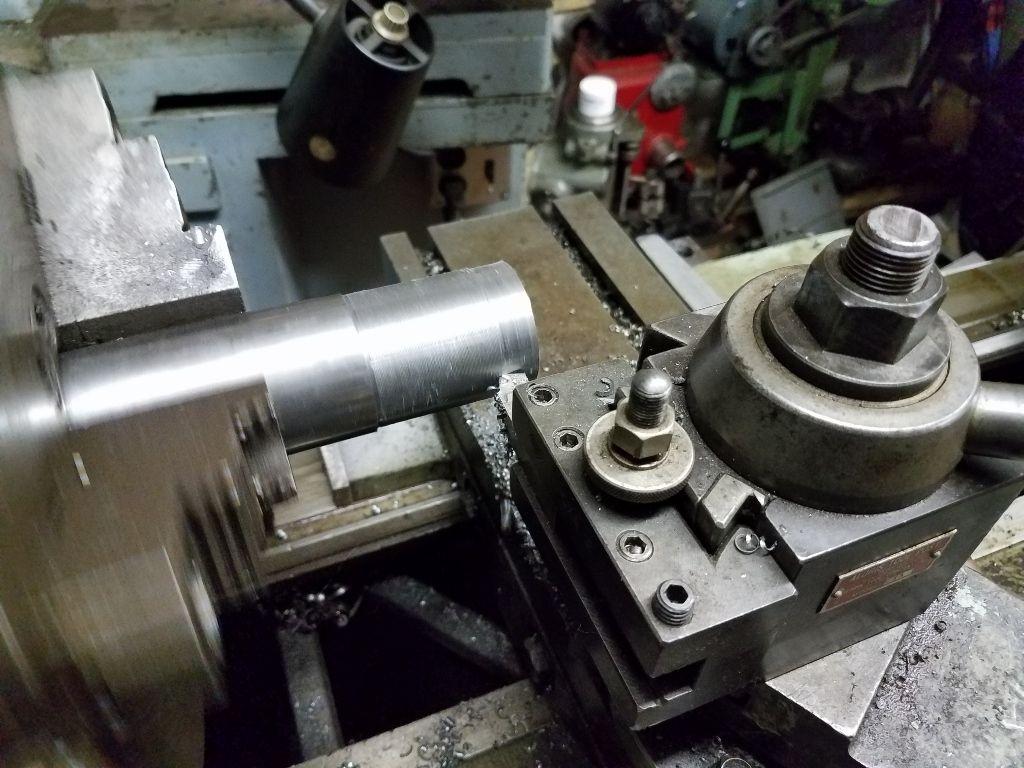

I'll discuss and photo document every step. From fitting an oversized bolt, milling the frame window, adding a stronger gate spring, making the cylinder, pawl and hammer/bolt timing, ratchet geometry, line indexing vs. line boring, heat treating, centering the barrel and cutting the cone, and making the front sight. It may take a week or two to get started, but it's coming. This first post is a placeholder....if it goes on the internet, I'm committing to the article. I hope folks find it informative.

As I've gotten older, I've fallen out of love with barrel bands on revolvers. Used to adore bands, but now my eyes don't take to them. Plus my preferred barrel length on Blackhawks is 6.0". The conversion will be the sister gun to this .500 Linebaugh:

The differences will be:

1) 6.0" straight taper barrel

2) Frame window opened 0.060"

3) Recessed cylinders (not a huge fan of them, but will do so here)

4) Jack Huntington Bisley mod with walnut panels

I'll discuss and photo document every step. From fitting an oversized bolt, milling the frame window, adding a stronger gate spring, making the cylinder, pawl and hammer/bolt timing, ratchet geometry, line indexing vs. line boring, heat treating, centering the barrel and cutting the cone, and making the front sight. It may take a week or two to get started, but it's coming. This first post is a placeholder....if it goes on the internet, I'm committing to the article. I hope folks find it informative.