Hi Mike,

That's disappointing isn't it? There are no SBH hammers made with the larger base. And new SBHs, standard Blackhawks, and Single Sixes look just like yours.

That's why I prefer the Montado hammers shown above, but they seem to be unobtainable these days. They have the larger diameter bases. The only hammers with the proper diameter bases to fit the newer grip frames are those newly designed hammers since 2005; New Vaqueros (including the checkered Montado hammer) and Flat Top Blackhawk hammers.

Here's the story and the reason:

The grip frame 'ear' height varies a bit as the frames get newer but there was one specific big height increase. To simplify production in about 1998, Ruger began a 1/16" height increase of the standard cylinder frame-to-grip frame mating surfaces on both sides of the hammer to match the Bisley model cyl frames so that any style grip frame could be assembled to any main frame. Therefore the 'ears' on all plow handle and birdshead grip frames had to be made 1/16" taller as well. So there's basically two sizes of grip frame ears: the earliest is short, .530" pre 1998 and the latest is the tall .590" after 1998; measured from the very top edge of the grip panel to the top of the ears.

That's why it's important that any acquired grip frame be a similar vintage to the Ruger that you want to put it on. If the ears are too tall for the main frame they can be dressed down to flush, but if too short for a newer main frame, it's more work to dress down the main frame and blued guns have to be touched up with cold blue.

The other problem is, Ruger has not seen fit to enlarge the bases of any of the existing hammer designs to match the grip frames with taller ears! If I use a small base hammer, I fit the grip frame ears to the hammer. I have to do this every time I install a newer grip frame such as the N Vaq and Flat Top XR3 style steel grip frames or newer XRE-RED steel grip frames on older New Models and Old Model Rugers. That's what I would recommend for your flat top.

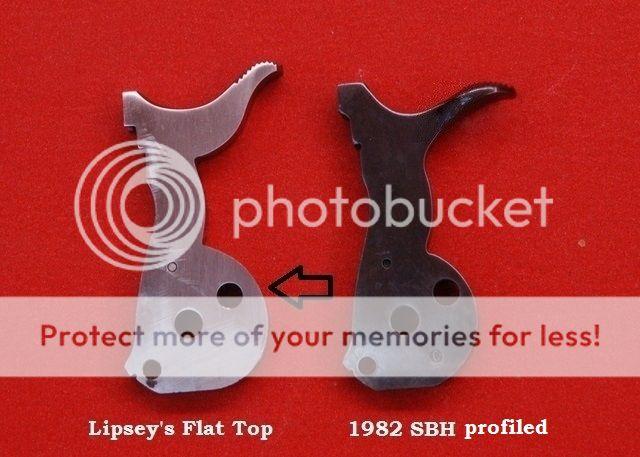

Small base hammers are 1.071" – 1.076".

New 2005 design with large base are 1.122" – 1.130" and with narrow shank.

Measured on the centerline of the two large holes from back of hammer base to over the full cock notch.

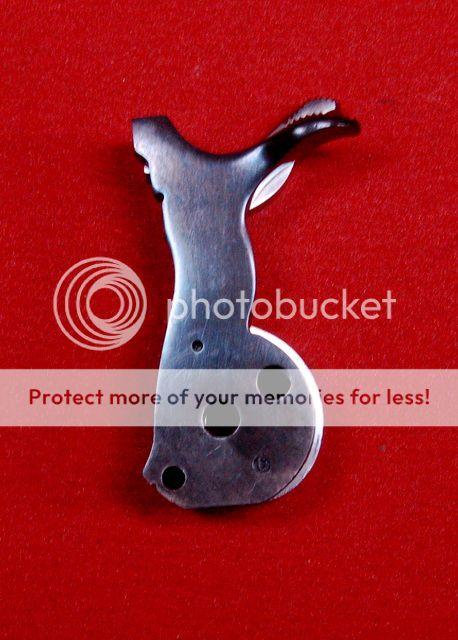

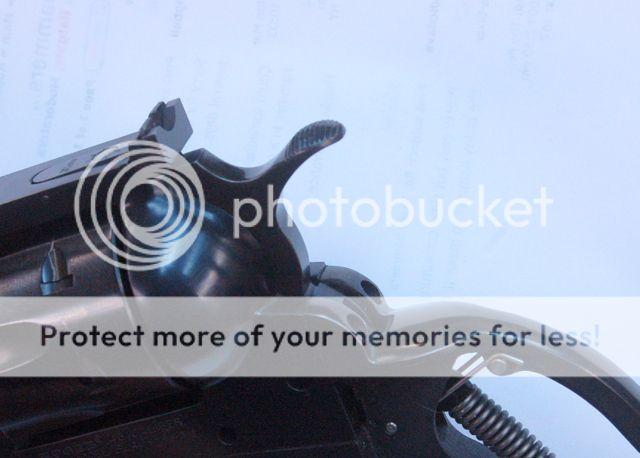

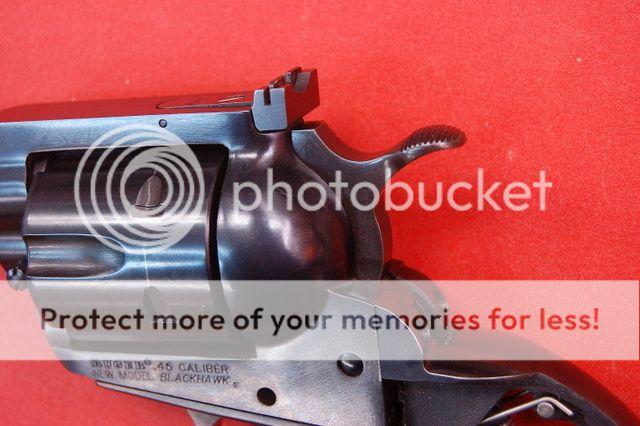

As shown in your photos above, narrower shank hammers (except Montado hammers) coincide with the larger base hammer design on the New Vaqs and the 1st anniversary new mid-size in 2005 flat tops and 2006 and later large frame flat tops, and in my opinion are much better looking. I know of no other reason for it other than the improved looks. For many years I was relieving the shanks by hand as is the Montado hammer on my 44 Spl flat top above.

44 Spl Vaquero mid-frame Sheriff Model, using a new Flat Top Blackhawk hammer with large base and narrow shank. Also Colt ejector, Belt Mtn Colt-style base pin. Ugly web behind trigger radiused.

Hope this helps,