JFB

Hunter

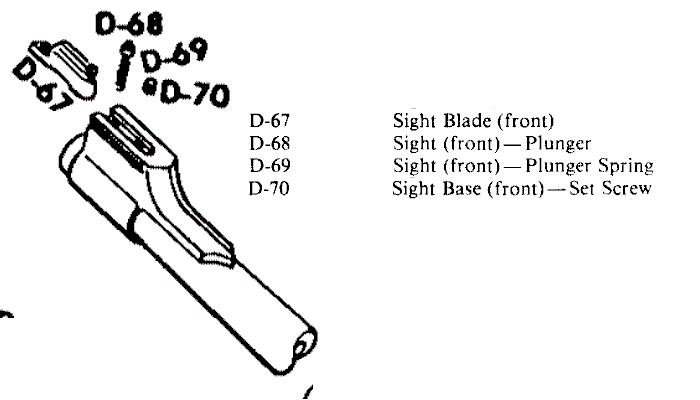

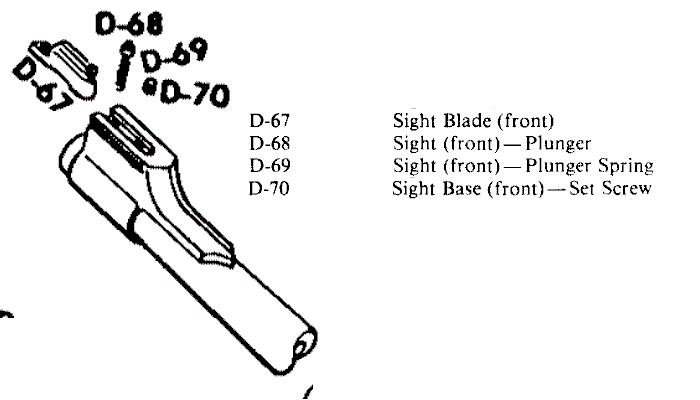

any tips on how to remove the front sight blade from an M77

I tried by depressing the plunger with a 1.5mm allen key and pushing on the bead with a plastic screw driver handle.

Not a good Ideal as the tip of the brass bead broke off

I tried by depressing the plunger with a 1.5mm allen key and pushing on the bead with a plastic screw driver handle.

Not a good Ideal as the tip of the brass bead broke off