Kind of went off on a tangent. In the very first post of the thread, I had a 9mm NM cylinder that for some reason had been messed with at the gas ring clearance. After taking note of the more correct remedies, I chose short term to insert a .029 shim to gain .001 cylinder shake with .005 to .006 at the barrel.

There was some discussion about OM and NM cylinders.

DGW pointed out that OM cylinders have a different chamber circle than NM and that if one could get the end shake, barrel to chamber clearances correct with an OM cyl in a NM, the chambers would still be misaligned with the barrel.

Now the tangent:

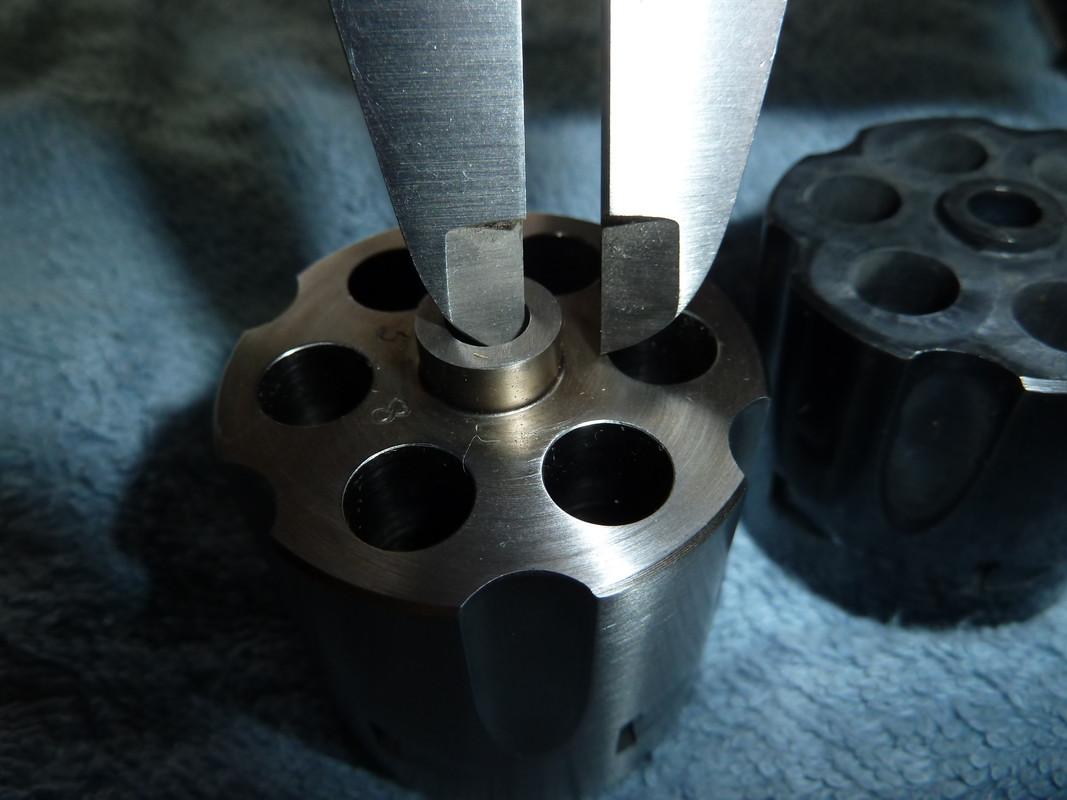

Since I have both an OM and NM .357, thought I would see for myself. The last series of three pics were to compare an OM and NM cylinder swap. The attempt to measure was to discover for myself that OM and NM cylinders have different chamber spacing circles, radii. OM chambers appear to be on a tighter circle, shorter radius.

Not pictured but also noted that an OM cyl has an overall diameter that is significantly less than a NM cylinder. And finally, if both cylinders are removed from the respective guns and slipped on to a common base pin, the difference in chamber spacing is readily apparent as is overall diameter.

So the warning, that even though one might be able to fit an OM-357 (or 9mm) cyl into a NM gun, the chambers would never be on centerline with the barrel at the firing position.

Apology to DGW from me for snipping his quote.

Just a NM guy venturing into the OM world...

DGW1949 said:

Please note that regardless of how the excessive end-shake is addressed, an OM-357 cylinder will still not work in a "big framed" NM gun. Reason is...the chambers will not align with the barrel close enough to allow the gun to be safely fired.

In other words, the distance from the base pin hole to the chamber is different on the two (differently-sized) guns, as-is the distance from the pin hole to the centerline of the barrel. PLUS the chambers are closer together in the OM cylinder.

None of that has anything to do with how long the cylinder is, or end shake, or B-C gap. On the other hand though, it has everything to do with aligning the cartridge to the barrel.

DGW